86

CRANKSHAFT POSITION (CKP)

SENSOR

Resistance

1. Set the meter selector to the OHMS position and test

as follows:

2. The meter reading must be within specification.

AC Voltage

NOTE: The battery must be at full charge for these

tests.

1. Set the meter selector to the AC Voltage position and

test as follows:

2. Crank the engine over using the electric starter. The

meter reading must be within specification.

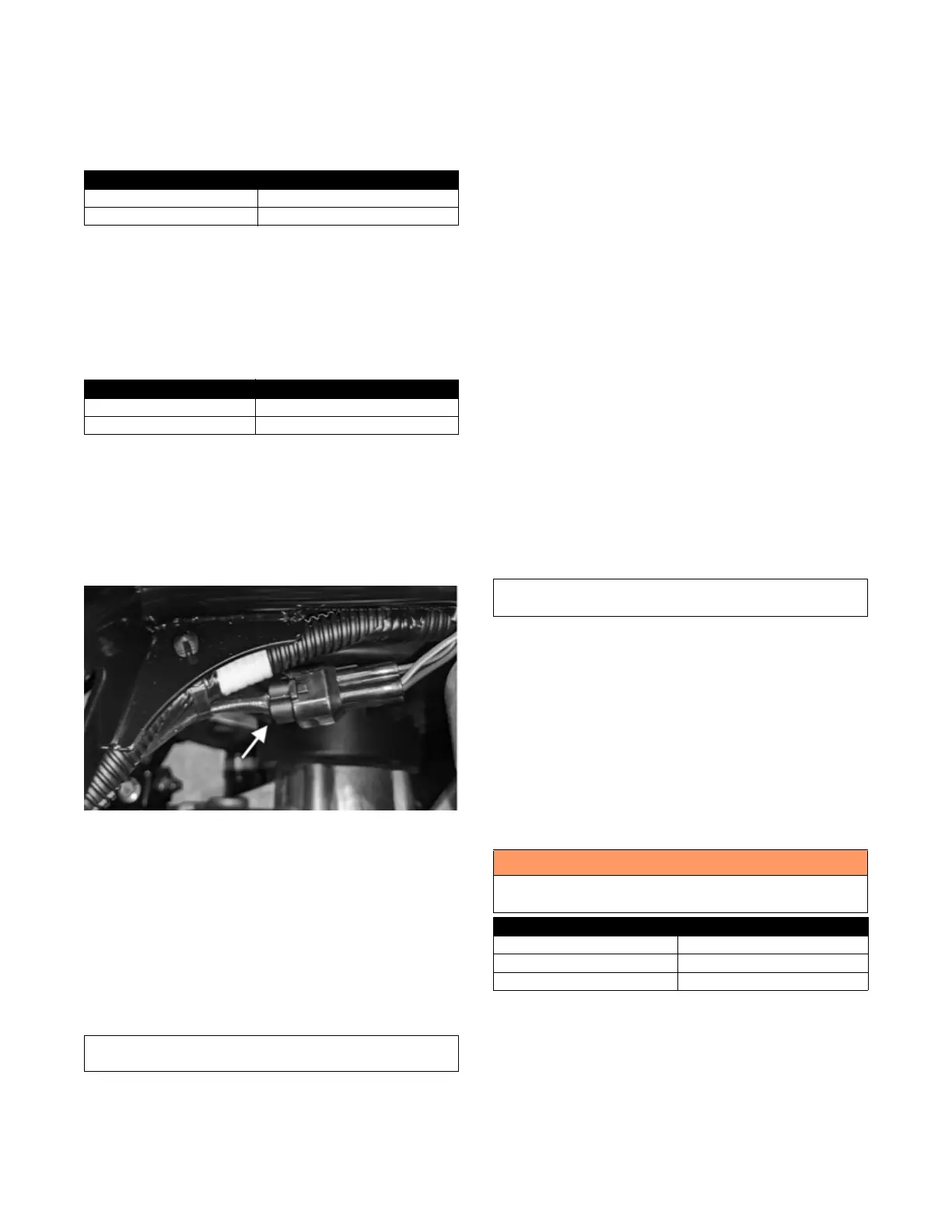

OXYGEN (O2) SENSOR

The sensor is located in the exhaust pipe.

1. Remove the seat. Unplug the connector located on

the rear left side of the ATV.

OHA105

2. On the sensor side of connector, connect the black

(negative) test lead to one white wire pin; then connect

the red (positive) test lead to the other white wire pin.

3. With the meter in the OHMS position, the reading

should be between 6.7-10.1 ohms.

NOTE: If the meter does not read as specified,

replace sensor.

MANIFOLD ABSOLUTE PRESSURE/

INLET AIR TEMPERATURE (MAP/IAT)

SENSOR

NOTE: Preliminary checks may be performed on

this component using the diagnostic mode on the LCD

gauge (see EFI Diagnostic System in this section).

NOTE: The ambient temperature of the engine and

in the intake and exhaust system must be at room

temperature (approximately 68° F/20° C) when per-

forming this test or an incorrect reading will occur.

1. Disconnect the MAP/IAT connector from the sensor

located on top of the throttle body.

2. Select DC Voltage on the tester and turn the ignition

switch to the ON position.

3. Connect the black tester lead to the black/pink wire

and the red tester lead to the orange/blue wire. The

meter should read 4.5-5.5 DC volts. If the meter does

not read as specified, check the ECM connector or

wiring.

4. Connect the MAP/IAT to the harness; then using

MaxiClips, connect the red tester lead to the

brown/white wire and the black tester lead to the

black/pink wire. With the engine running at idle

speed, the meter should read approximately 2.5 DC

volts (MAP sensor signal).

5. Connect the red tester lead to the green/red wire.

With the engine at idle, the meter should read

approximately 2.9 DC volts.

NOTE: If the meter does not read as specified,

replace the sensor.

ENGINE COOLANT TEMPERATURE

(ECT) SENSOR

NOTE: Preliminary checks may be performed on

this component using the diagnostic mode on the LCD

gauge (see EFI Diagnostic System in this section).

1. Connect the meter leads (selector in OHMS position)

to the sensor terminals.

2. Suspend the sensor and a thermometer in a container

of cooking oil; then heat the oil.

NOTE: Neither the sensor nor the thermometer

should be allowed to touch the bottom of the con-

tainer or inaccurate readings will occur. Use wire

holders to suspend the sensor and thermometer.

3. If the readings are not as indicated ± 10%, the sensor

must be replaced.

4. Install the sensor and tighten securely.

5. Connect the leads.

SPEED SENSOR

NOTE: Prior to testing the speed sensor, inspect the

three-wire connector on the speed sensor for contami-

nation, broken pins, and/or corrosion.

WIRE COLOR RESISTANCE

Red to White 200 Ohms

Black to Brown 200 Ohms

WIRE COLOR VOLTAGE

Red to White 2.0 AC Volts

Black to Brown 2.0 AC Volts

Component data can be retrieved using the Dealer

Diagnostic System. Utilize the Sensor Data screen.

Component data can be retrieved using the Dealer

Diagnostic System. Utilize the Sensor Data screen.

! WARNING

Wear insulated gloves and safety glasses. Heated oil

can cause severe burns.

TEMPERATURE RESISTANCE

-20° C (-4° F) 18.8k Ohms

40° C (105° F) 1.14k Ohms

100° C (212° F) 155 Ohms

Loading...

Loading...