87

1. Set the meter selector to the DC Voltage position.

2. With appropriate needle adapters on the meter leads,

connect the red tester lead to the orange lead; then

connect the black tester lead to the black lead.

OHA102

3. Turn the ignition switch to the ON position.

4. The meter must show battery voltage.

5. Leave the black tester lead connected; then connect

the red tester lead to the pink/white wire.

6. Slowly move the ATV forward or backward; the

meter must alternate between 0 volts and battery

voltage.

NOTE: If the sensor tests are within specifications,

the LCD gauge must be replaced (see Steer-

ing/Body/Controls).

To replace a speed sensor, use the following procedure:

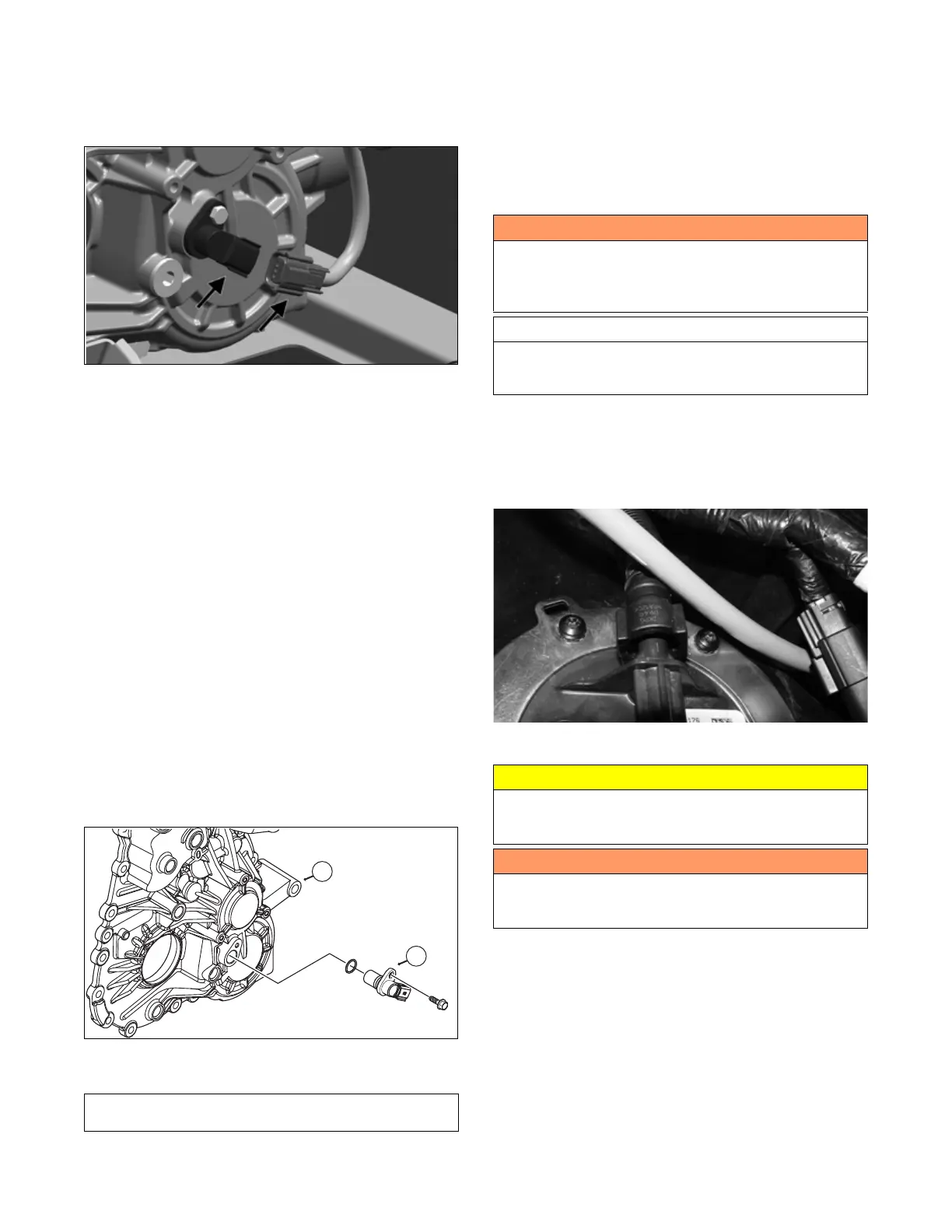

1. Disconnect the three-wire connector from the speed

sensor harness or from the speed sensor (B); then

remove the cap screw securing the sensor to the tran-

saxle (A).

2. Remove the sensor from the sensor housing account-

ing for an O-ring.

3. Install the new speed sensor into the transaxle (A) with

new O-ring lightly coated with multi-purpose grease;

then secure the sensor (B) with the cap screw (threads

coated with blue Loctite 242). Tighten securely.

OHA101

FUEL PUMP/FUEL LEVEL SENSOR

NOTE: Preliminary checks may be performed on

this component using the diagnostic mode on the LCD

gauge (see EFI Diagnostic System in the Electrical

System section).

The electric fuel pump, fuel level sensor, and fuel pump

float are not serviceable components. If any component

fails, it must be replaced.

Testing

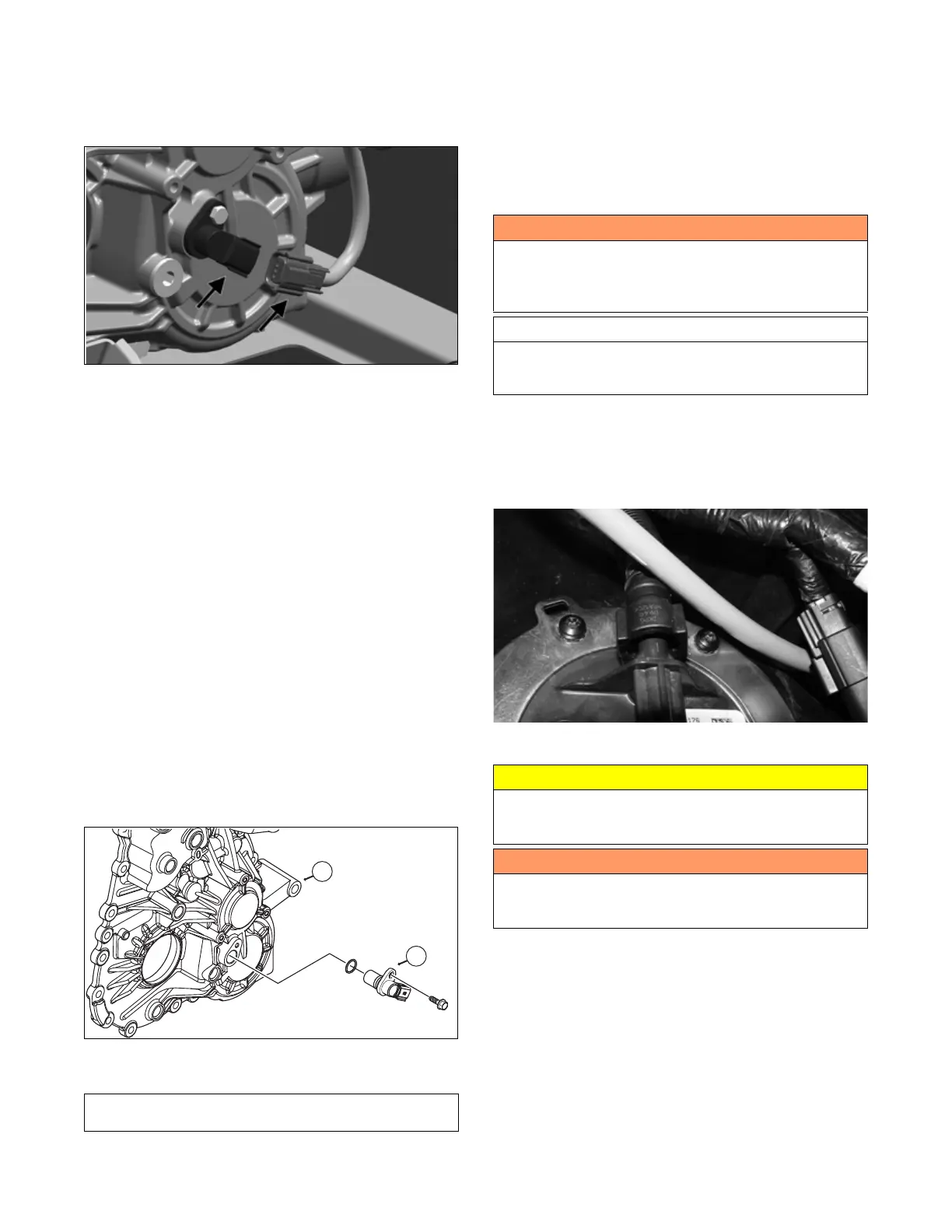

1. Blow any debris from the fuel pump connection

using compressed air.

2. Disconnect the quick connect fitting by pushing it

toward the fuel pump fitting; the press the quick con-

nect button(s) and remove the gasline hose.

XR171

3. Install Fuel Pressure Tester in-line between the fuel

pump and the gasline hose.

4. Turn the ignition switch to the ON position. The fuel

pressure should build until the pump shuts off. Pres-

sure should read 3.0 kg-cm

2

(43 psi).

Component data can be retrieved using the Dealer

Diagnostic System. Utilize the Sensor Data screen.

! WARNING

Whenever any maintenance or inspection is made on

the fuel system during which there may be fuel leakage,

there should be no welding, smoking, open flames, etc.,

in the area.

AT THIS POINT

Prior to removing the electric fuel pump, the following

check should be performed to determine that removal

is necessary.

CAUTION

Failure to push the fitting toward the fuel pump will

result in damage to the fitting causing the gasline hose

to be replaced.

! WARNING

Gasoline may be under pressure. Place an absorbent

towel under the connector to absorb any gasoline spray

when disconnecting.

Loading...

Loading...