88

XR172

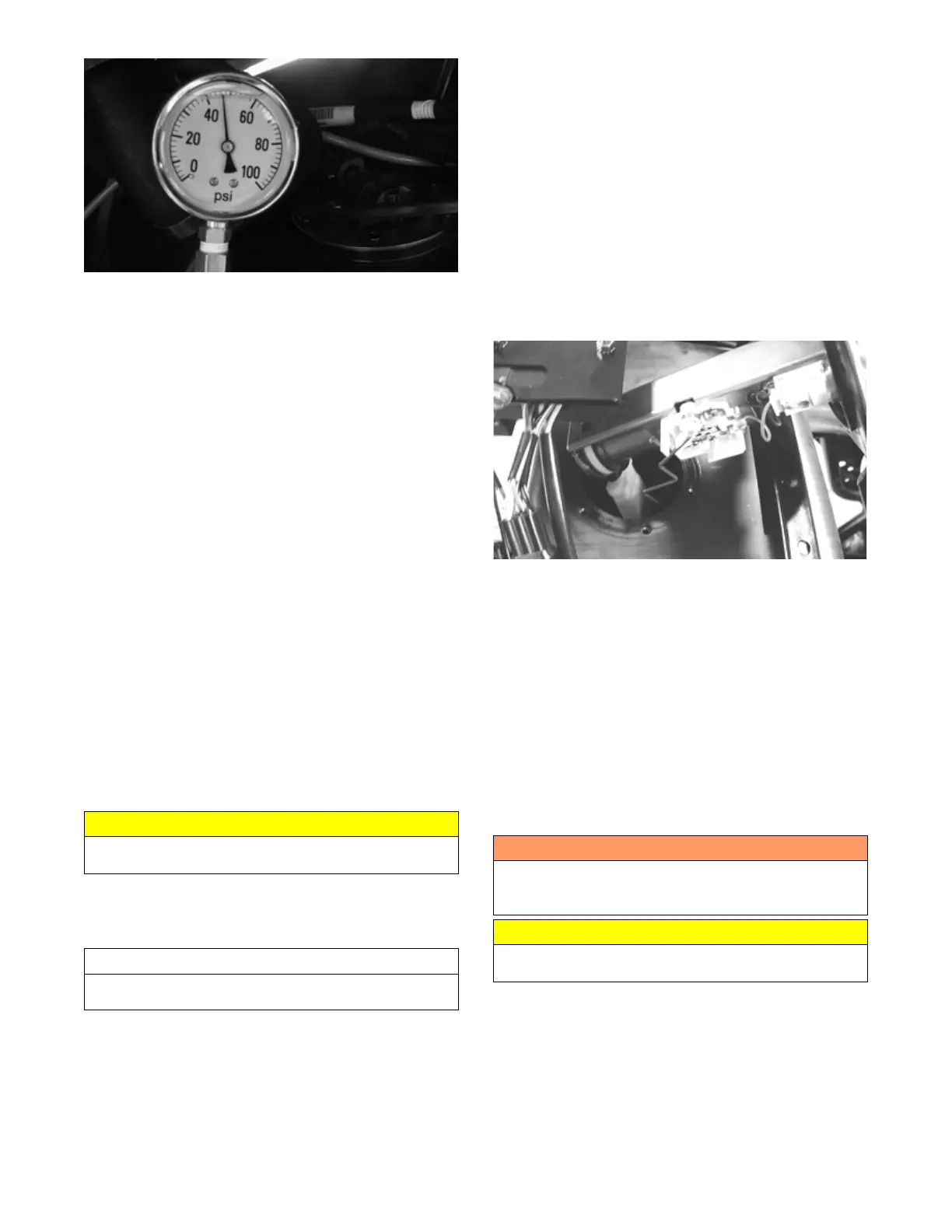

NOTE: The fuel pump will cycle 5-10 seconds after

the ignition key is turned on.

5. If the pump is producing fuel pressure that is out of

specification, check all electrical connectors and verify

the pump is getting proper voltage (battery voltage).

6. Connect a meter to the power supply leads with the red

tester lead to the red wire and the black tester lead to the

black wire; then turn the ignition switch to the ON posi-

tion. The meter should read battery voltage.

NOTE: Low voltage will produce a low fuel pressure

reading.

7. If normal battery voltage is present and the ground

wire has been checked for continuity to chassis,

replace the fuel pump. If no voltage is present, deter-

mine if the fuel pump fuse, relay, wiring, tilt sensor,

or ECM is causing no voltage.

NOTE: If the gauge is flashing FUEL OFF, the tilt sen-

sor system has intentionally deactivated the fuel system.

Removing

1. Disconnect the gasline hose and fuel pump connectors.

2. Remove the screws securing the fuel pump to the gas

tank; then make a reference mark on the fuel pump and

tank.

3. Lift out the fuel pump assembly; then guide the pump

and float lever through the opening in the gas tank.

4. Using duct tape or other suitable means, cover the

fuel pump opening.

Inspecting

1. Inspect the fuel screen and blow clean with low pres-

sure compressed air.

2. Move the float lever and check for free movement.

The float assembly should return to the lower posi-

tion without force. If not, replace the fuel pump

assembly.

3. Test the fuel level sensor by connecting a meter to

the fuel level sensor leads; then select OHMS. The

meter should show 5 ohms at full fuel position and

95 ohms at empty fuel position.

NOTE: If readings are erratic, clean the resistor

wiper and resistor with clean alcohol and retest. If

still not correct, replace the fuel level sensor.

Installing

1. Mark the new fuel pump with a reference mark in the

same location as the removed pump; then place the

new gasket on the pump.

2. Remove the material covering the fuel pump open-

ing; then carefully guide the fuel pump into position

taking care not to damage the float or float lever.

KX190

3. Rotate the fuel pump until the match marks align;

then install the mounting screws and tighten securely

using a crisscross pattern.

NOTE: It is critical to install the fuel pump with the cor-

rect orientation to ensure adequate float lever clearance.

4. Connect the wires, fuel hose, and spring clamp; then

turn the ignition switch to the ON position. Note that

the fuel pump runs momentarily and the fuel gauge

indicates the proper fuel level.

5. With the transmission in neutral and brake lever lock

engaged, start the engine and check for normal oper-

ation. Check for any fuel leaks.

TILT SENSOR

Tilt sensor is located on front of the steering post frame

bracket. Remove seat, front fender and storage box to

access.

Supply Voltage

1. Disconnect the three-wire connector from the sensor;

then select DC Voltage on the meter and connect the

red tester lead to the orange wire (C) and the black

tester lead to the pink/black wire (A).

CAUTION

Take care not to damage the float or float arm or

replacement of the entire assembly will be necessary.

AT THIS POINT

If the pump has failed earlier test and must be replaced,

proceed to INSTALLING.

! WARNING

Incorrect installation of the tilt sensor could cause sud-

den loss of engine power which could result in loss of

vehicle control resulting in injury or death.

CAUTION

Do not drop the tilt sensor as shock can damage the

internal mechanism.

Loading...

Loading...