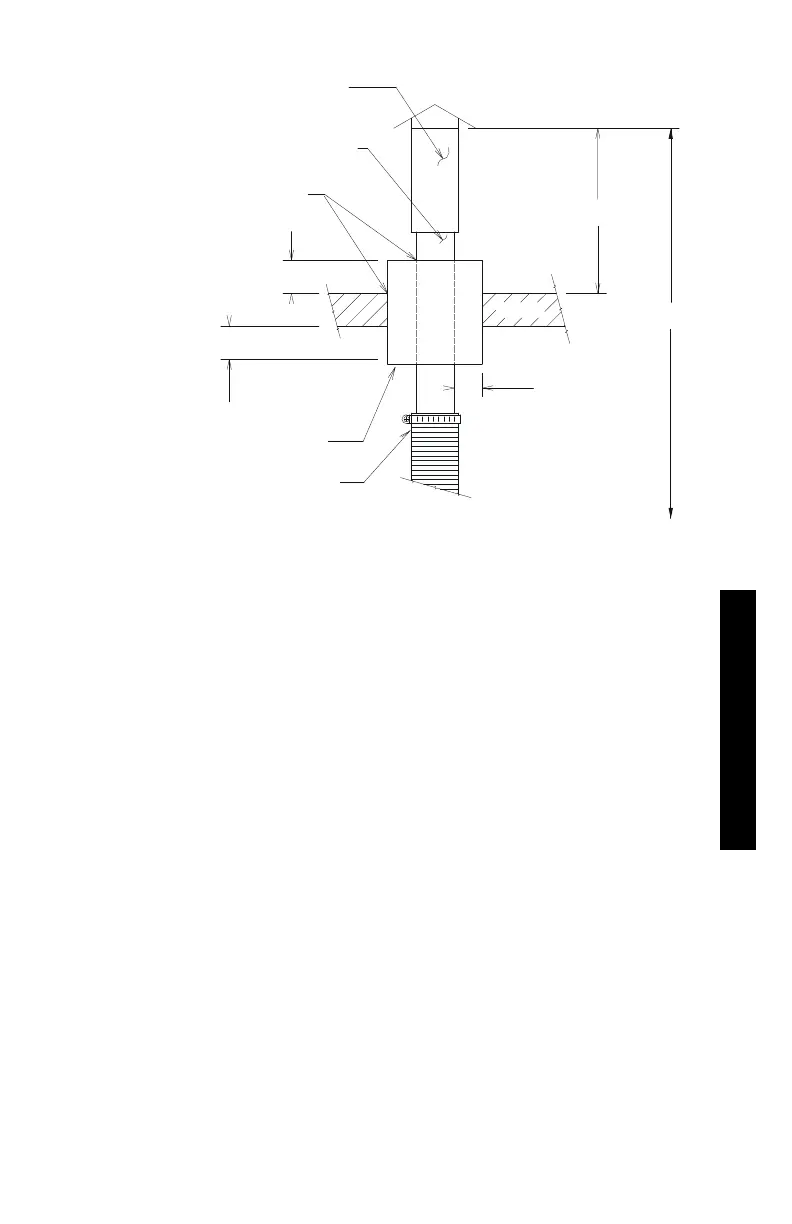

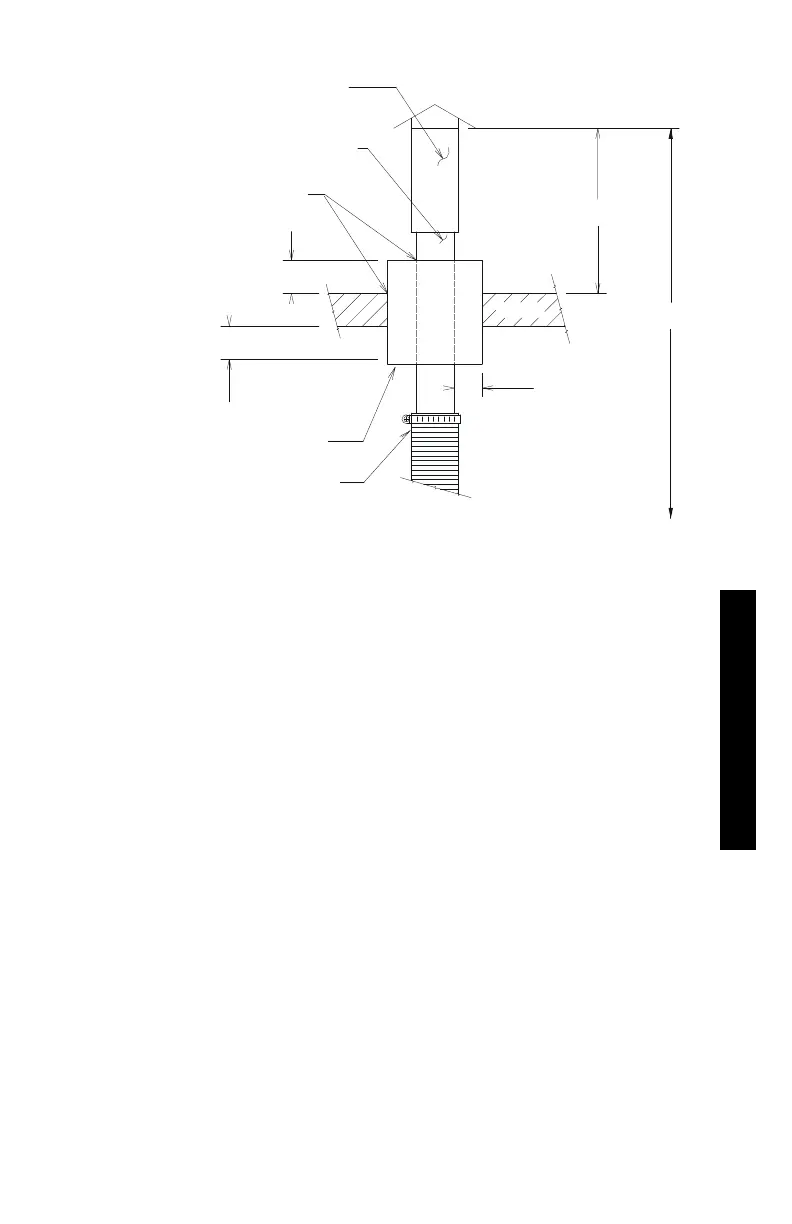

Troxler NTO 3–9

3. INST

LLATION

ROOF

6" (SEE NOTE 2)

4" DIA GALVANIZED METAL DUCT

(REMOVE ANY DAMPER FROM DUCT)

9" (SEE NOTE 1)

36" MIN

(SEE NOTE 3)

4" DIA

ALVANIZED METAL

AP

(REMOVE ANY DAMPER FROM CAP)

SEAL AGAINST MOISTURE (SEE NOTE 5)

GALVANIZED METAL THIMBLE

4" DIA FLEXIBLE METAL DUCT W/ CLAMP

15' MAX LENGTH(PROVIDED BY TROXLER)

15 FT MAX

(SEE NOTE 6

9" (SEE NOTE 1)

NOTES:

1. Galvanized metal thimble must extend at least 23 cm (9 in.)

above and below roof.

2. Galvanized metal thimble must provide at least 15 cm (6 in.) of

clearance between the duct and the nearest combustible

material.

3. The point where exhaust exits the cap must be at least 91 cm

(36 in.) above the roof.

4. The minimum thickness of all galvanized metal parts is 28

gauge, or that which is called for in local building codes,

whichever is thicker.

5. Seal all joints between thimble and roof and between thimble

and duct with a high-temperature caulk.

6. The overall length of all ducts should not exceed 4.6 m (15 ft)

from the top of the oven to the point of exhaust.

7. Do not locate exhaust point near air intakes for building. Refer

to local building codes and/or a licensed HVAC contractor for

recommended/required distance.

8. No component shall have a damper, screen, louver, or other

such device that may become clogged with soot over time.

9. Refer to local building codes and/or a licensed HVAC contractor

for more details.

Figure 3–4. Roof Penetration

Loading...

Loading...