Unpacking and Setting up the System 2–7

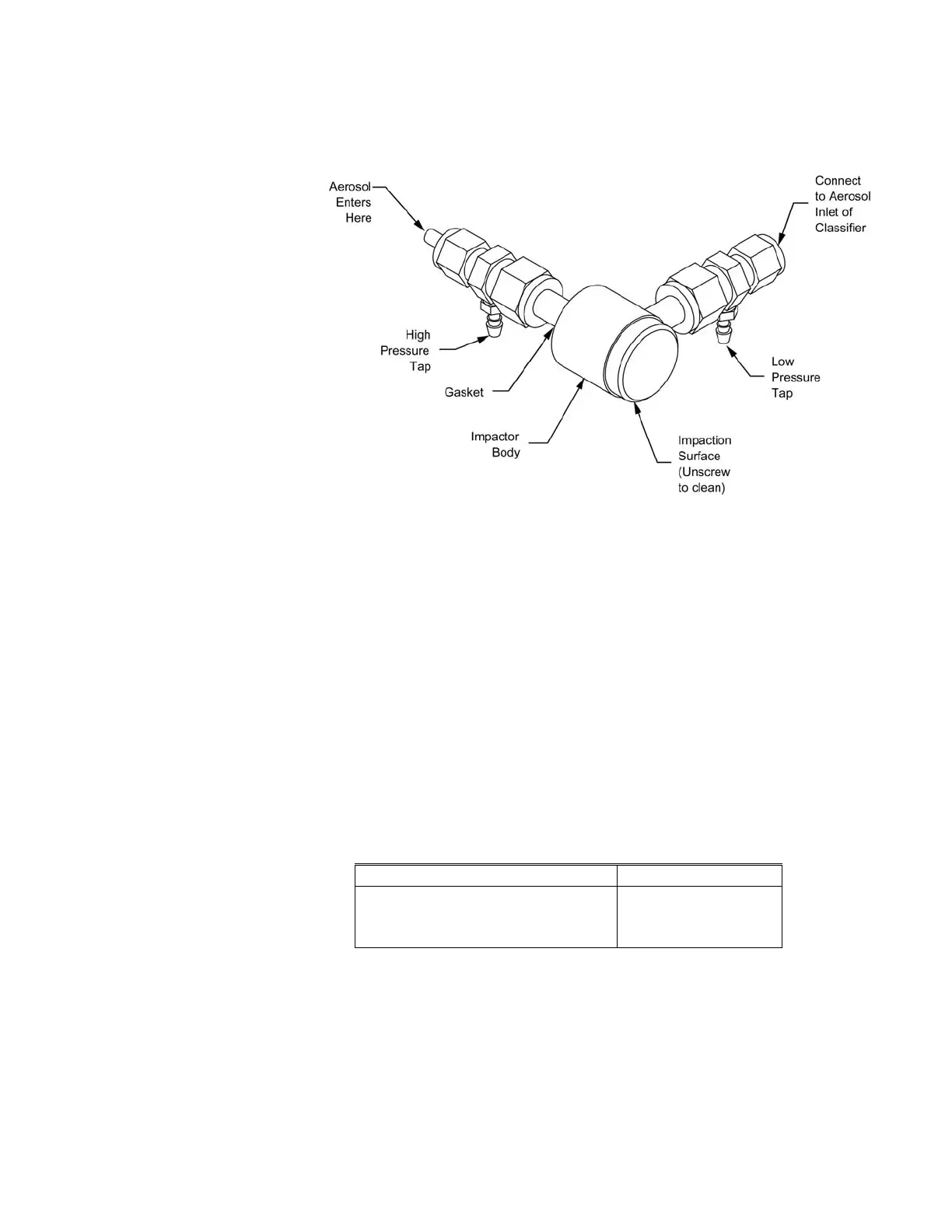

side of the impactor (fitting with low pressure tap) is attached to the

aerosol inlet of Classifier (Figure 2-4).

Figure 2-4

Impactor Inlet

There are three nozzle sizes to choose from. The nozzle size and flow

rate determine the largest particle size that can be sampled within

each SMPS measuring size range. For best results, use Table 2-2 to

determine the correct nozzle to use for the flow you set. Each nozzle

is interchangeable and can be screwed into the impactor body with

a gasket to seal the thread. Using the Classifier display, you can

view the flow rate directly from the pressure drop measured across

the impactor. The Classifier stores an internal calibration curve for

each impactor size and serial number. Only use the impactor

nozzles that come with the Classifier because the calibration curves

stored in the Classifier are unique for the nozzles.

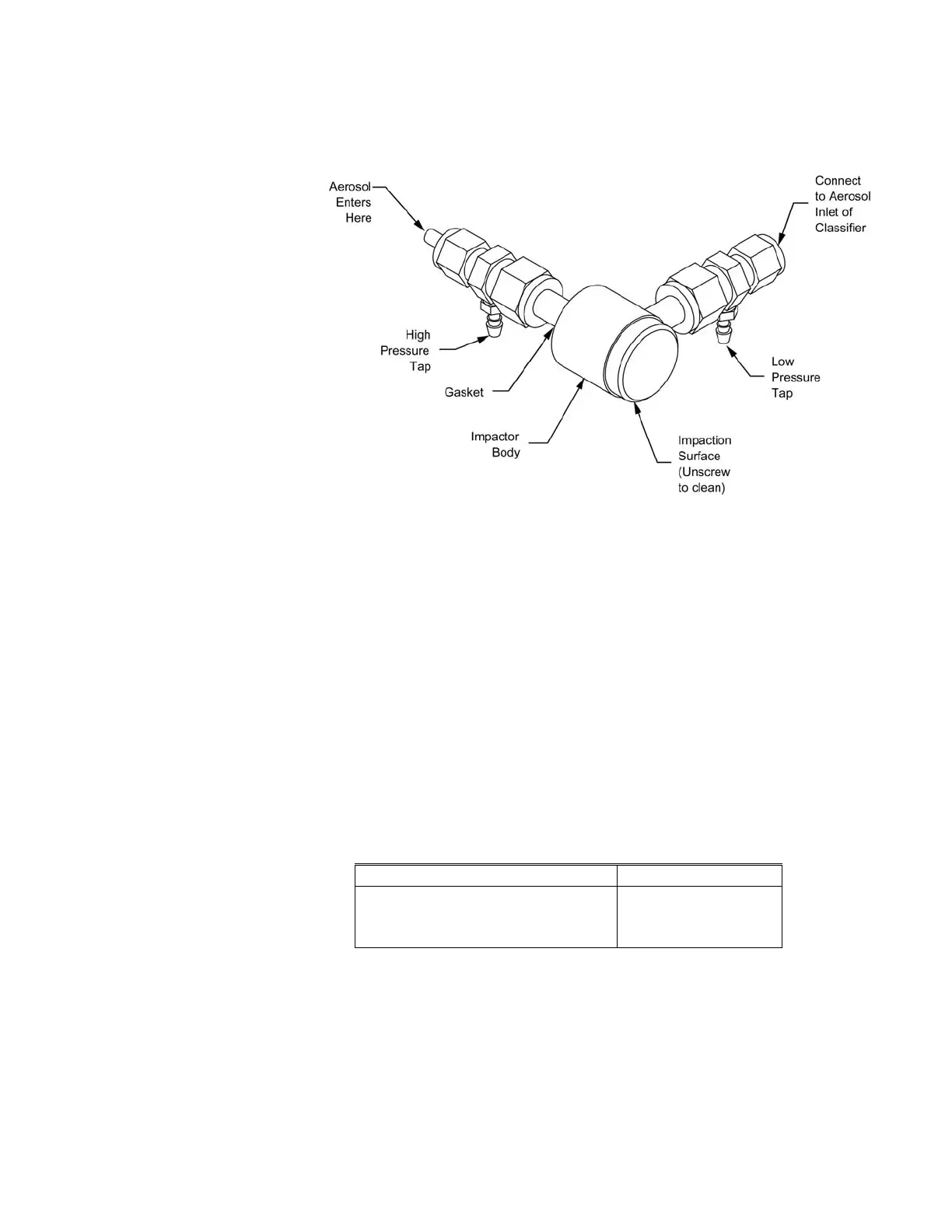

Table 2-2

Typical Flow Range for Each Impactor Nozzle

Aerosol Inlet Flow Range (L/min) Nozzle Size (cm)

0.2 to 0.8 0.0457

0.3 to 1.0 0.0508

0.6 to 2.1 0.071

When you have selected a nozzle size you need to physically install

it in the impactor body and then set the corresponding nozzle size

on the front panel of the Classifier.

Loading...

Loading...