7-1

CHAPTER 7

Troubleshooting

This chapter tells how to troubleshoot the Classifier.

Detecting Particles When the Collector-

Rod Voltage is Not Switched on

When the collector-rod voltage is not on, the airstream flowing out

of the Monodisperse Flow connector should be particle-free. If

particles are detected in the airstream, the Classifier may have one

or more of the following problems:

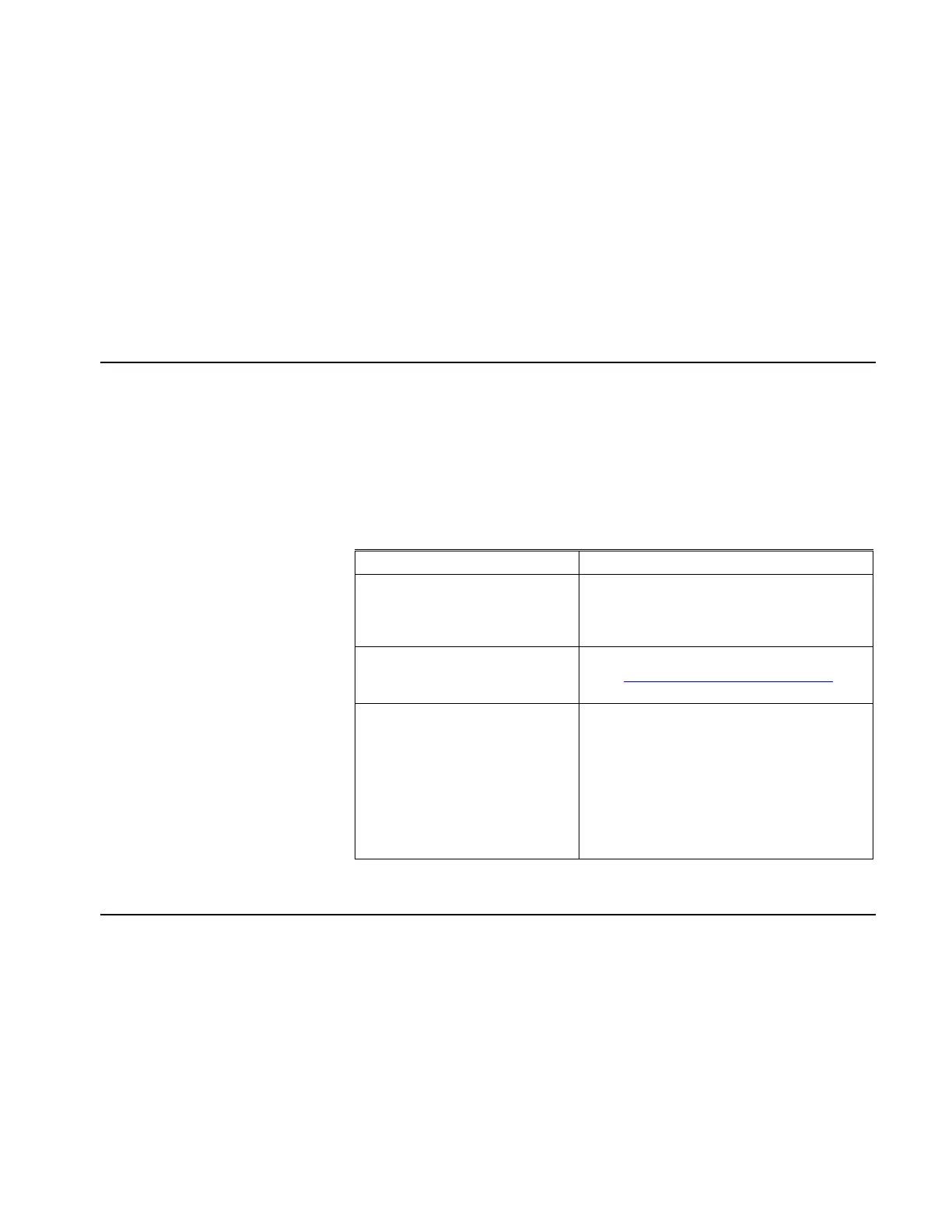

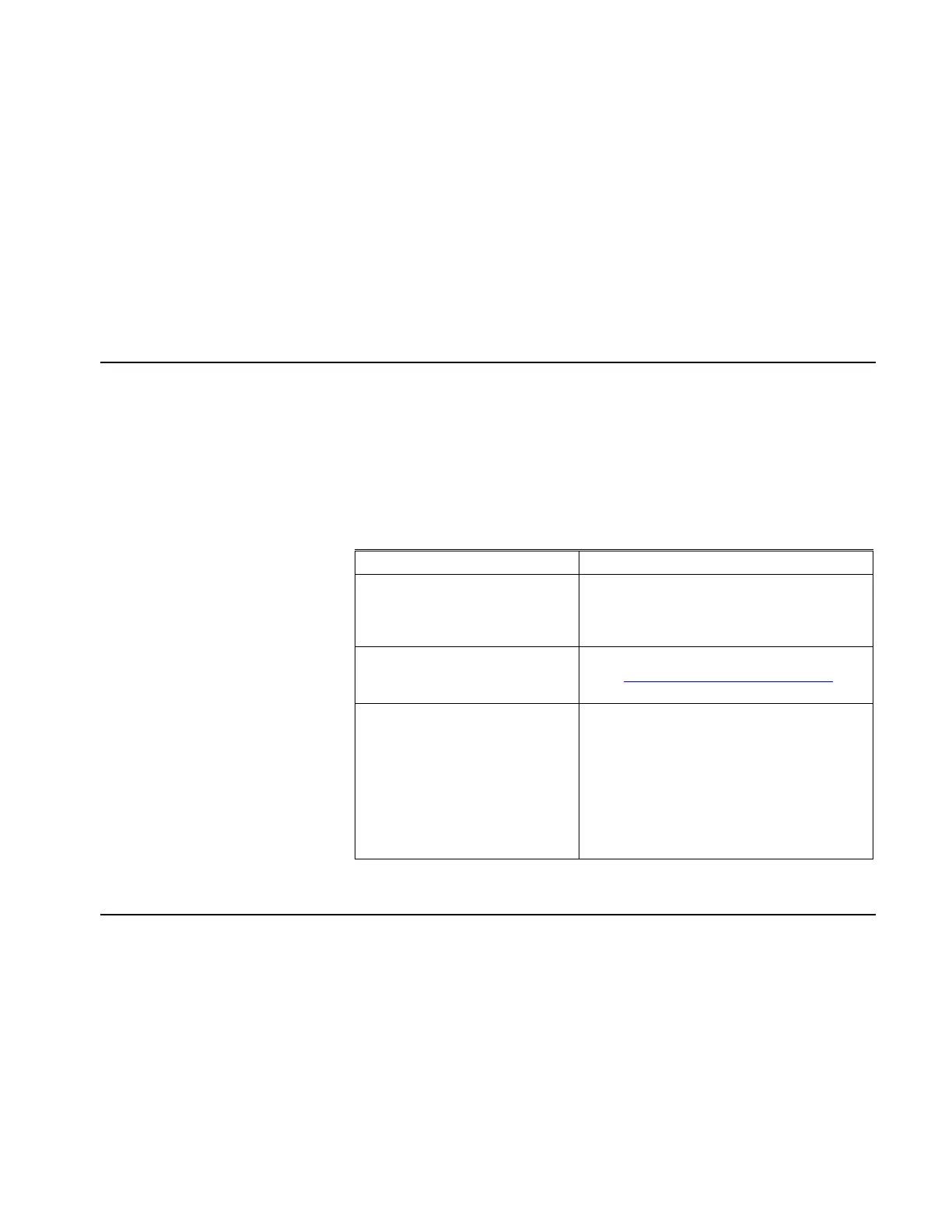

Problem Solution

The ratio of aerosol to clean-

sheath air flow is too high

The imbalance ratio can occur if the

ratio of aerosol to clean-sheath-airflow

exceeds 1:10. Change flows so that ratio

is below 1:10.

The sheath-air filter has a

leak

Replace the sheath-air filter cartridge

(see “Replacing the Filter Cartridges

” in

Chapter 6).

Turbulent flow has developed

in the differential mobility

analyzer

If particles still appear after these

checks, decrease sheath and

polydisperse flows so that the total flow

rate inside the analyzer is less than 10

liters per minute. If particles disappear

using these steps, it suggests that

turbulent flow has developed in the

analyzer at normal flow rates. Contact

TSI for repair information.

Testing for Leaks

Whenever an air leak is suspected or a significant part of the

airflow system has been reassembled, perform a leak test to assure

proper performance. Begin by isolating the DMA from the Classifier

using these steps:

1. Disconnect all tubing from the DMA.

Loading...

Loading...