2.5 Safety-related Electrical Interfaces

Max joint

speed in

normal

mode

[rad/s]

[s]

time

0.5240.024

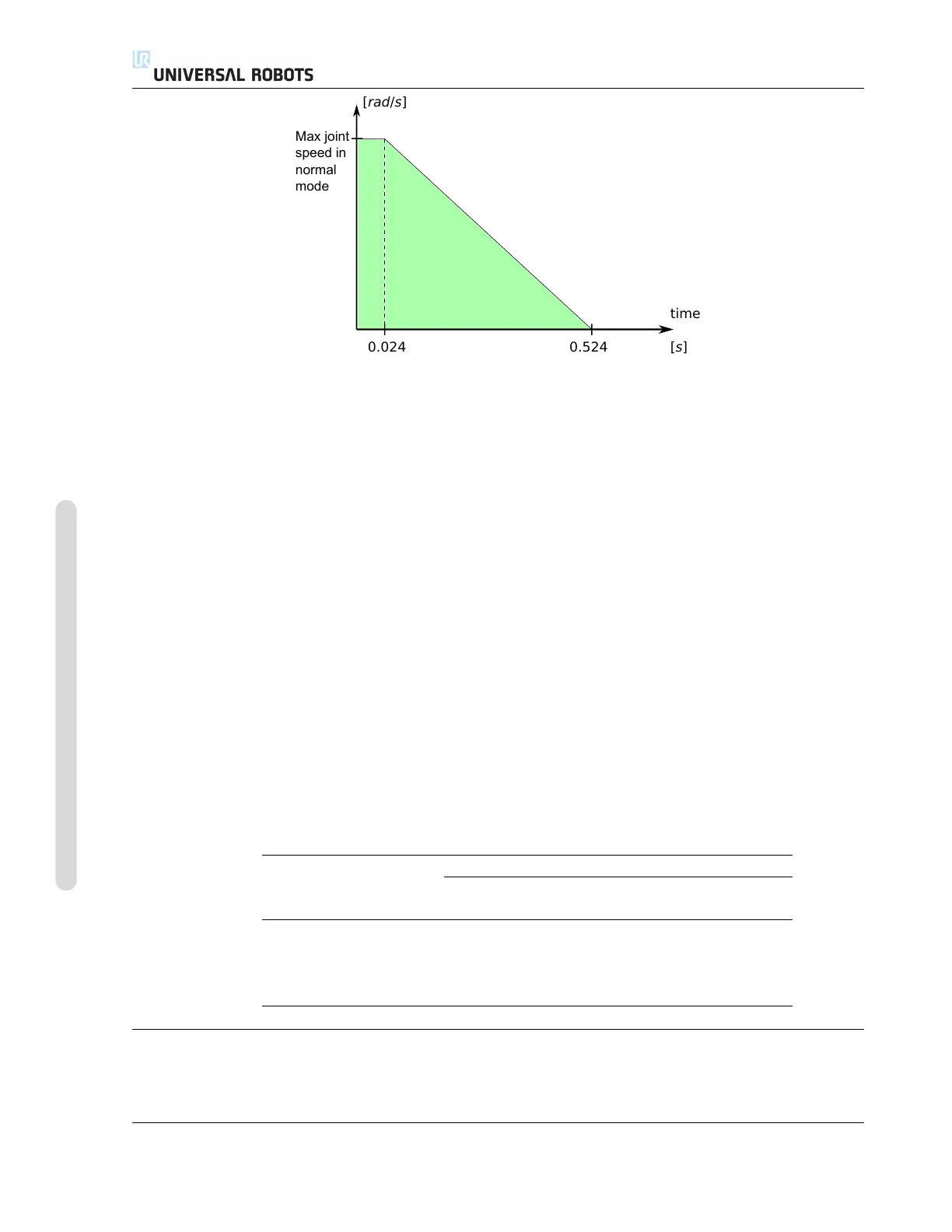

Figure 2.2: The green area below the ramp is the allowed speeds for a joint during braking. At time 0 an

event (emergency stop or safeguard stop) is detected at the safety processor. Deceleration begins after 24 ms.

3. If a joint is at rest (joint speed is less than 0.2

rad

/s), it is monitored that it does not move more

than 0.05 rad from the position it had when the speed was measured below 0.2

rad

/s.

Additionally, for a Stop Category 1, the safety system monitors that after the robot arm is at rest,

the powering off is finalized within 600 ms. Furthermore, after a Safeguard Stop input, the robot

arm is only allowed to start moving again after a positive edge on the safeguard reset input occurs.

If any of the above properties are not satisfied, the safety system issues a Stop Category 0.

A transition to Reduced mode triggered by the reduced mode input is monitored as follows:

1. The safety system accepts both Normal and Reduced mode limit sets for 500 ms after the reduced

mode input is triggered.

2. After 500 ms, only the Reduced mode limits are in effect.

If any of the above properties are not satisfied, the safety system issues a Stop Category 0.

A Stop Category 0 is performed by the safety system with the performance described in the fol-

lowing table. The worst-case reaction time is the time to stop and to de-energize (discharge to an

electrical potential below 7.3 V) a robot running at full speed and payload.

Worst Case

Safety Input Function Detection

Time

De-energizing

Time

Reaction Time

Robot Emergency Stop 250 ms 1000 ms 1250 ms

Emergency Stop Button 250 ms 1000 ms 1250 ms

System Emergency Stop 250 ms 1000 ms 1250 ms

Safeguard Stop 250 ms 1000 ms 1250 ms

2.5.2 Safety-related Electrical Outputs

The table below gives an overview of the safety-related electrical outputs:

UR3/CB3 I-18 Version 3.10

Copyright © 2009–2019 by Universal Robots A/S. All rights reserved.

Loading...

Loading...