Parameters vacon • 100

Service support: find your nearest Vacon service center at www.vacon.com

6

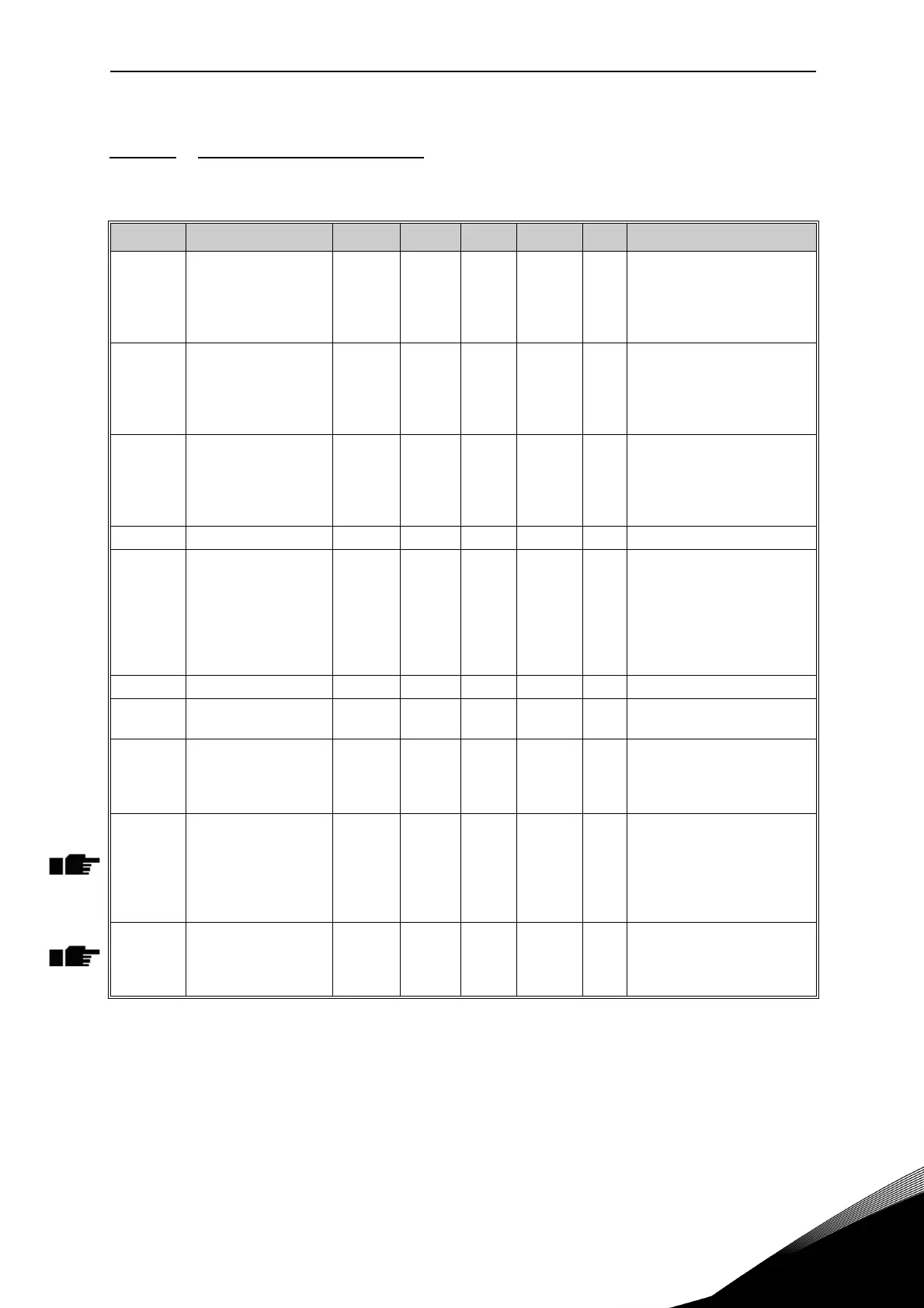

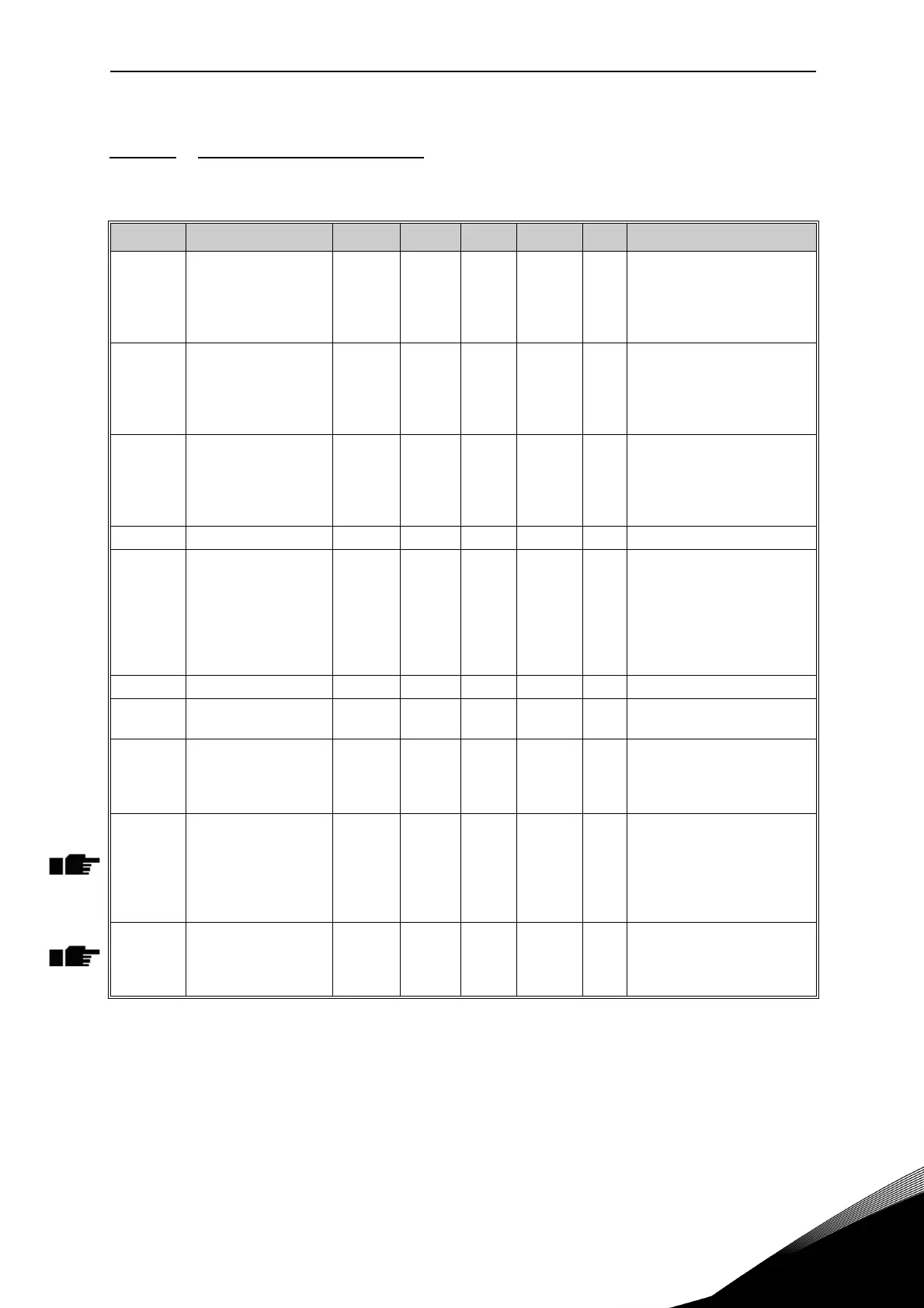

6.1.14 Group 3.13: PID Controller

6.1.14.1 Group 3.13.1: Basic Settings

Table 91. PID controller 1 basic settings

Code Parameter Min Max Unit Default ID Description

P3.13.1.1 Gain 0.00 1000.00 % 100.00 118

If the value of the parameter

is set to 100% a change of

10% in the error value causes

the controller output to

change by 10%.

P3.13.1.2 Integration Time 0.00 600.00 s 1.00 119

If this parameter is set to

1,00s a change of 10% in the

error value causes the con-

troller output to change by

10.00%/s.

P3.13.1.3 Derivation Time 0.00 100.00 s 0.00 132

If this parameter is set to

1,00s a change of 10% in the

error value during 1.00 s

causes the controller output

to change by 10.00%.

P3.13.1.4 ProcessUnitSel. 1 38 1 1036 Select unit for actual value.

P3.13.1.5 ProcessUnitMin Varies Varies Varies 0 1033

Value in Process units at 0%

feedback or setpoint.

This scaling is done for moni-

toring purpose only. The PID

controller still uses the per-

centage internally for feed-

backs and setpoints.

P3.13.1.6 ProcessUnitMax Varies Varies Varies 100 1034 See above.

P3.13.1.7 ProcessUnitDeci 0 4 2 1035

Number of decimals for pro-

cess unit value

P3.13.1.8 Error inversion 0 1 0 340

0 = Normal (Feedback < Set-

point -> Increase PID output)

1 = Inverted (Feedback < Set-

point ->

Decrease PID output

)

P3.13.1.9 Dead Band Varies Varies Varies 0 1056

Dead band area around the

setpoint in process units.The

PID output is locked if the

feedback stays within the

deadband area for a pre-

defined time.

P3.13.1.10 Dead Band Delay 0.00 320.00 s 0.00 1057

If the feedback stays within

the dead band area for a pre-

defined time, the output is

locked.

Loading...

Loading...