wc_tx003871gb_FM10.fm

155

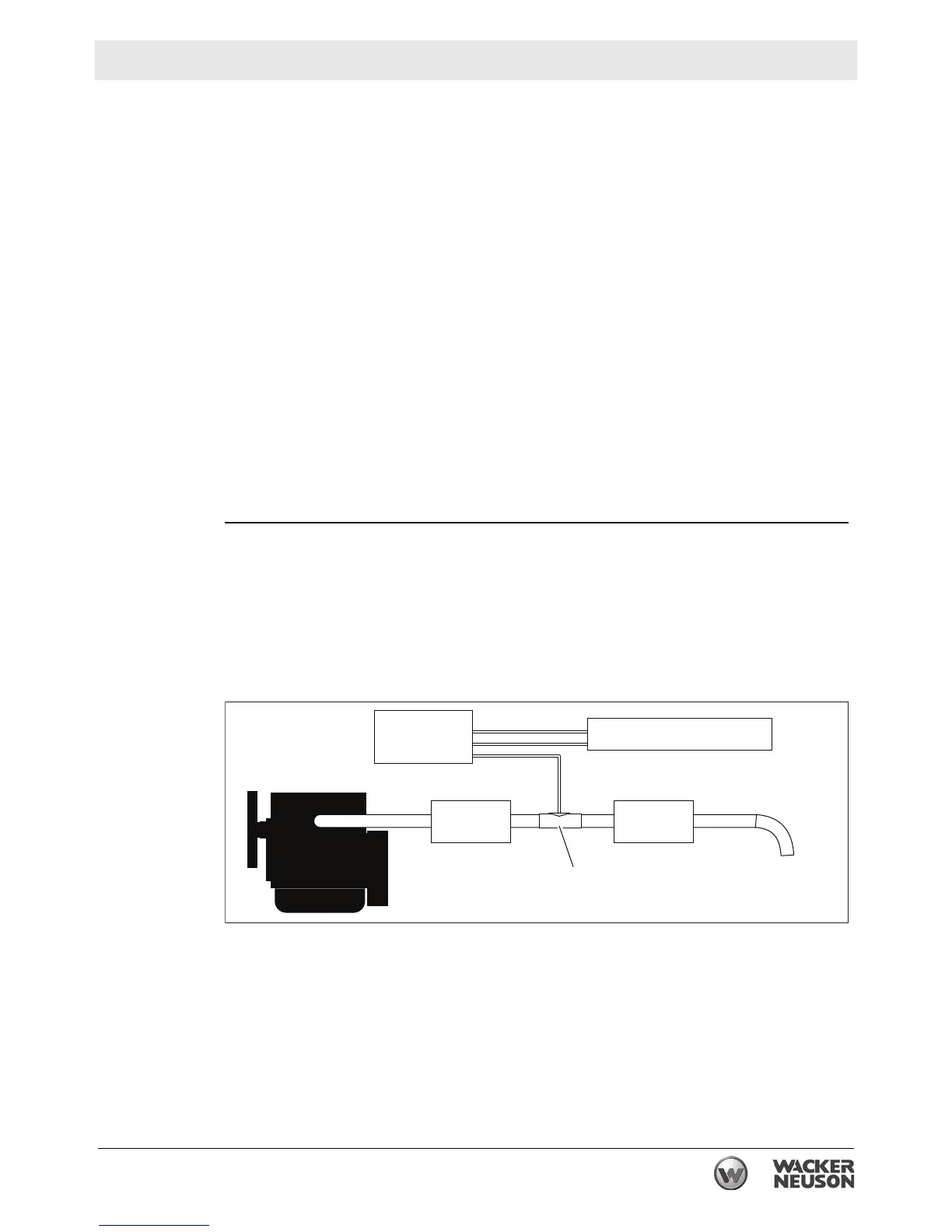

Machines with Aftertreatment Exhaust System

15 Machines with Aftertreatment Exhaust System

15.1 How the Aftertreatment Exhaust System Works

Background

Many Wacker Neuson Generators with Tier 4 engines use an aftertreatment

exhaust system to reduce emissions. There are five main components to the

system:

■ Heat

■ Diesel Exhaust Fluid (DEF)

DEF is a urea-based chemical reactant designed specifically for use in SCR

systems to reduce nitrogen oxides (NO

x

) emissions.

■ Selective Catalytic Reduction (SCR) system

An SCR is a catalytic converter which houses a catalyst made of base metal

oxides (such as titanium, vanadium, and tungsten oxides).

■ Diesel Oxidation Catalyst (DOC)

A DOC is a catalytic converter that oxides pollutants such as carbon monoxide,

hydrocarbons, and organic diesel particulates.

■ Decomposition Reactor Tube (DRT)

A DRT is a tube between the DOC and the SCR into which the DEF is

introduced (dosed) into the exhaust stream.

How it works

► The exhaust is first treated by the DOC.

► Exhaust (NO

x

) emissions flow through the DOC into the DRT.

► DEF is injected into the DRT.

The amount and frequency is controlled by the DEF supply module.

► The DEF vaporizes and decomposes to form ammonia and carbon dioxide.

Within the SCR catalyst, the NOx are catalytically reduced by the ammonia into

water and nitrogen. These are then released through the exhaust elbow.

Interaction

The system requires very little interaction by the operator. Items that require

attention are:

■ DEF tank—refill as required

■ DEF supply module filter—change every 4500 hours

■ Manual regeneration—a manual regeneration of the system may be necessary

if the engine is unable to complete an automatic regeneration cycle.

DEF Tank

DOC SCR

DRT

DEF Supply

Module

wc_gr012291

Loading...

Loading...