70

CHAPTER 6 - DETAILED PARAMETER DESCRIPTION

Range

[Factory Setting]

Parameter Description / Notes

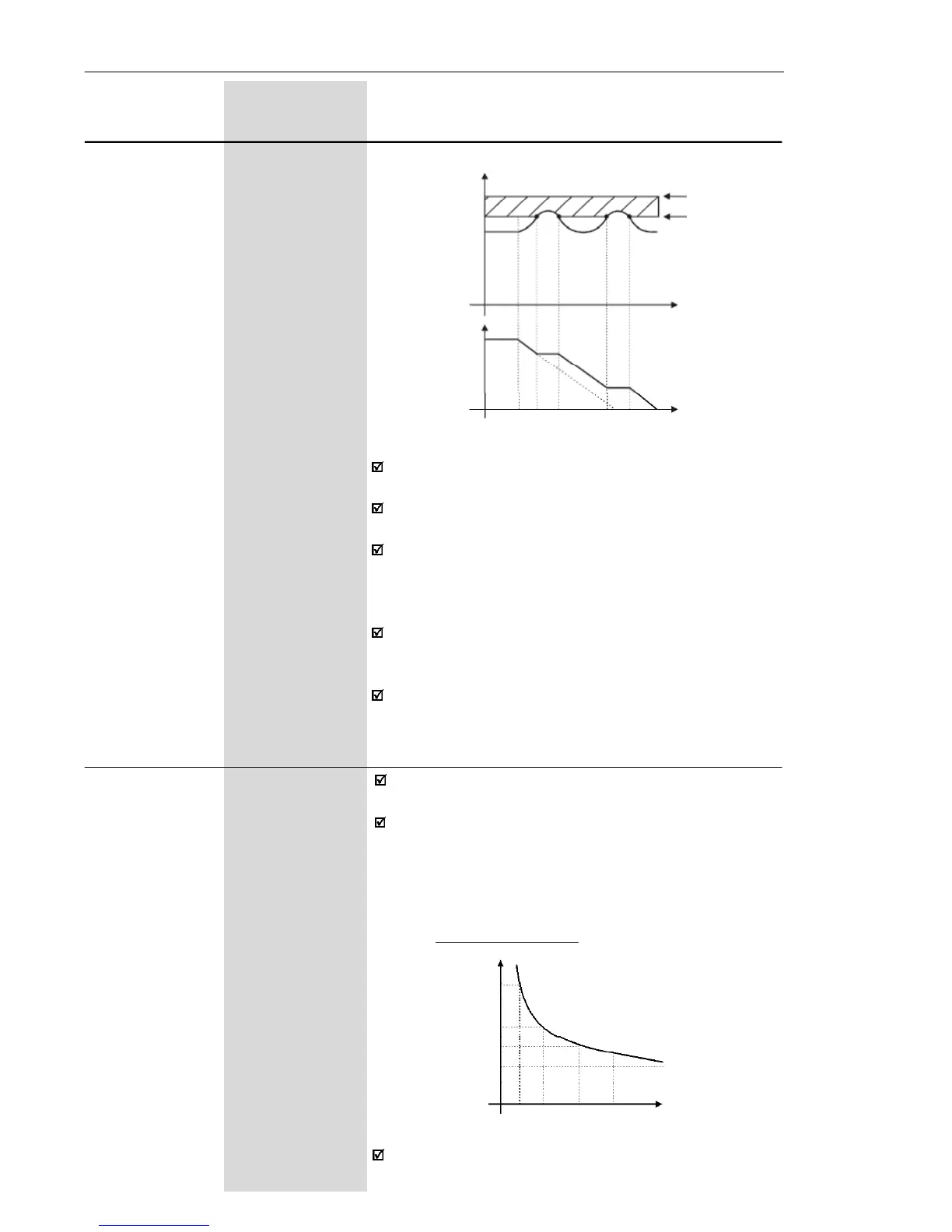

Figure 6.12 - Deceleration curve with DC Link voltage regulation

By this function an optimized deceleration time

(minimum) is achieved for the driven load.

This function is useful in applications with medium

inertia that require short deceleration times.

In case of overvoltage trip during the decelearation,

you must reduce gradually the value of P151 or

increase the time of the deceleration ramp (P101 and/

or P103).

The motor will not stop if the line is permanently with

overvoltage (U

d

> P151). In this case, reduce the line

voltage, or increase the value of P151.

If even with these settings the motor does not

decelerate within the required time, you will have the

alternative to increase P136;

E01 - Overvoltage

Hardware limit

CI Voltage

Ud (P004)

Time

Output

Frequency

(Motor

Speed )

Rated Ud

P151

Time

DC Link

Voltage

P156 0.3 x I

nom

to 1.3 x I

nom

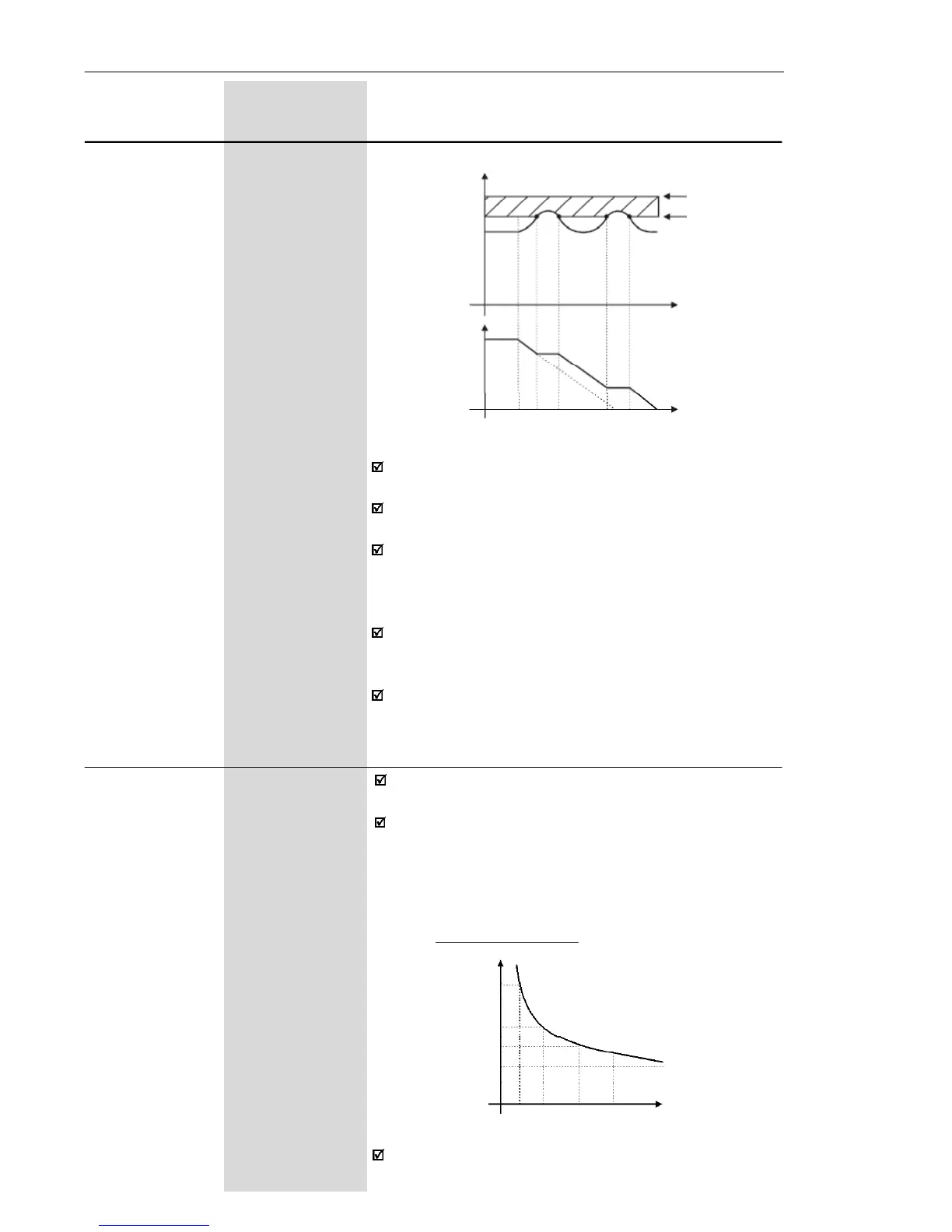

Motor Overload [ 1.2 x P295 ]

Current 0.1 A

This function is used to protect the motor against

overload (I x t function - E05).

The motor overload current is the current level above

which the inverter will consider the motor operating

under overload. The higher the difference between the

motor current and the overload current, the sooner the

I x t function - E05 - will act.

Figure 6.13 - I x t function – Overload detection

Parameter P156 shall be set to a value 10 % to 20 %

higher than the motor rated current.

3.0

2.0

1.5

1.0

15 30 60 90

Time (s)

Motor Current (P003)

Overload Current

Loading...

Loading...