111

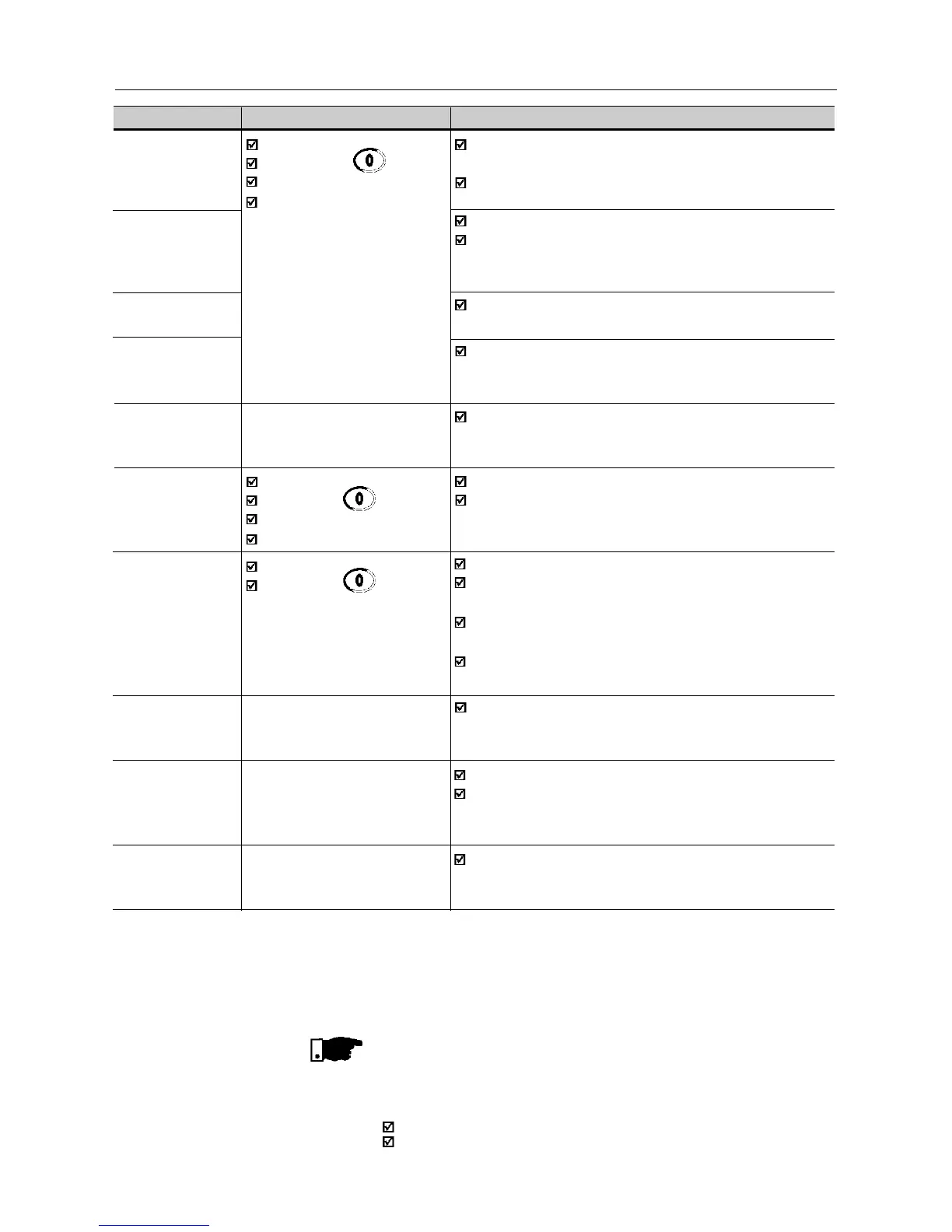

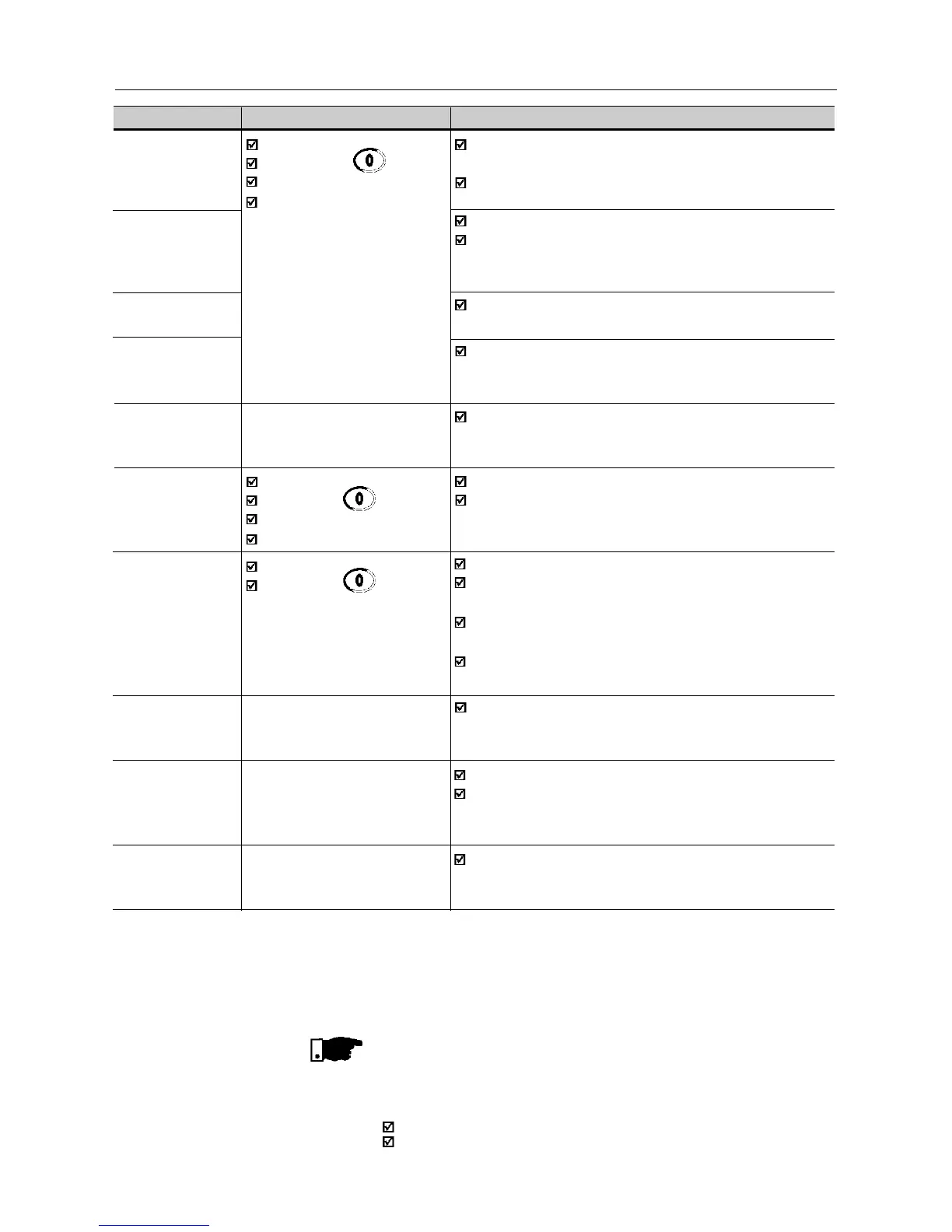

DIAGNOSTICS AND TROUBLESHOOTING

Note:

(1) In case of E04 Fault due to inverter overtemperature, allow the

inverter to cool down before trying to reset it.

In the types 10A/200-240 and 10A/380-480V fitted with internal

Class A RFI-filters, the fault E04 can be caused by internal airflow

overtemperature. Please check blower installed inside.

FAULT RESET

(1)

POSSIBLE CAUSES

E04 Power-on Ambient temperature too high (>40

o

C) and/or output

Inverter Manual (key ) current too high.

Overtemperature Auto-reset Blower locked or defective.

DI

E05 P156 set too low for the motor that is being used.

Motor/Inverter Motor is under an actual overload condition.

Overload

Ixt Function

E06 Ani DI (DI3 and/or DI4) programmed for external fault

External Fault detection is open (not connected to GND - XC1).

E08 Electrical noise.

CPU Error

(Watchdog)

E09 Contact WEG Memory with corrupted values.

Program Memory (refer to section 7.3)

Error (Checksum)

E10 Power-on Defective contact in the HMI-CFW08-RS cable.

Keypad Manual (key ) Electrical noise in the installation

Error Auto-reset (electromagnetic interference).

DI

E14 Power-on Motor is not connected to the inverter output.

Self-Tuning Manual (key ) Wrong motor connection (wrong voltage, lack of one

Fault phase).

The used motor is too small for the inverter

(P401<0.3 x P295). Use V/Fcontrol.

The value of P409 (stator resistance) is too high for the used

inverter.

E24 It is automatically reset Incompatible parameters were programmed

Programming when the incompatible Refer to table 5.1.

error parameters are changed

E31 It is reset automatically Keypad cable misconnected.

Keypad (HMI) when the communication Electrical noise in the installation (electromagnetic

Connection Fault between inverter and the interference).

keypad is reestablished.

E41 Contact WEG Inverter power circuit is defective.

Self- Diagnosis (refer to section 7.3)

Fault

NOTE!

Long motor cables (longer than 150ft (50 m)) can generate excessive

capacitance to ground. This can cause nuisance ground fault trip and

consequently disabling by E00 fault immediately after the inverter has

been enabled. Solution:

Reduce the switching frequency (P297).

Connect a load reactor in series with the motor supply line.

Refer to Section 8.16.

Loading...

Loading...