39

INSTALLATION AND CONNECTION

Analog Input

AI1

AI2

Factory Deafult Setting

Frequency / Speed

Reference (remote mode)

No function

Dip

Switch

S1.1

S1.2

Selection

OFF: 0 ... 10V

ON: 4 ... 20mA or 0 ... 20mA

OFF: 0 ... 10V

ON: 4 ... 20mA or 0 ... 20mA

Table 3.5 - Dip switch configuration

NOTE!

Jumpers S1 are factory set to OFF position (0 ... 10V signal).

If it's used a 4 ... 20mA signal, set parameter P235 and/or P239, that

defines the signal type at AI1 and AI2, respectively.

The parameters related to the analog inputs are: P221, P222, P234,

P235, P236, P238, P239 e P240. For more details, please refer to

Chapter 6.

During the signal and control wire installation note please the following:

1) Cable cross section: 20 ... 14 AWG (0.5...1.5mm²).

2) Max. Torque: 0.50 N.m (4.50 lbf.in).

3) XC1 wiring must connected with shielded cables and installed

separately at a distance of 10 cm each other for lengths up to 100m

and at distance of 25cm each other for lengths over 100m. If the crossing

of these cables is unavoidable, install them perpendicular, maintaining

a mimimum separation distance of 2 in (5 cm) at the crossing point.

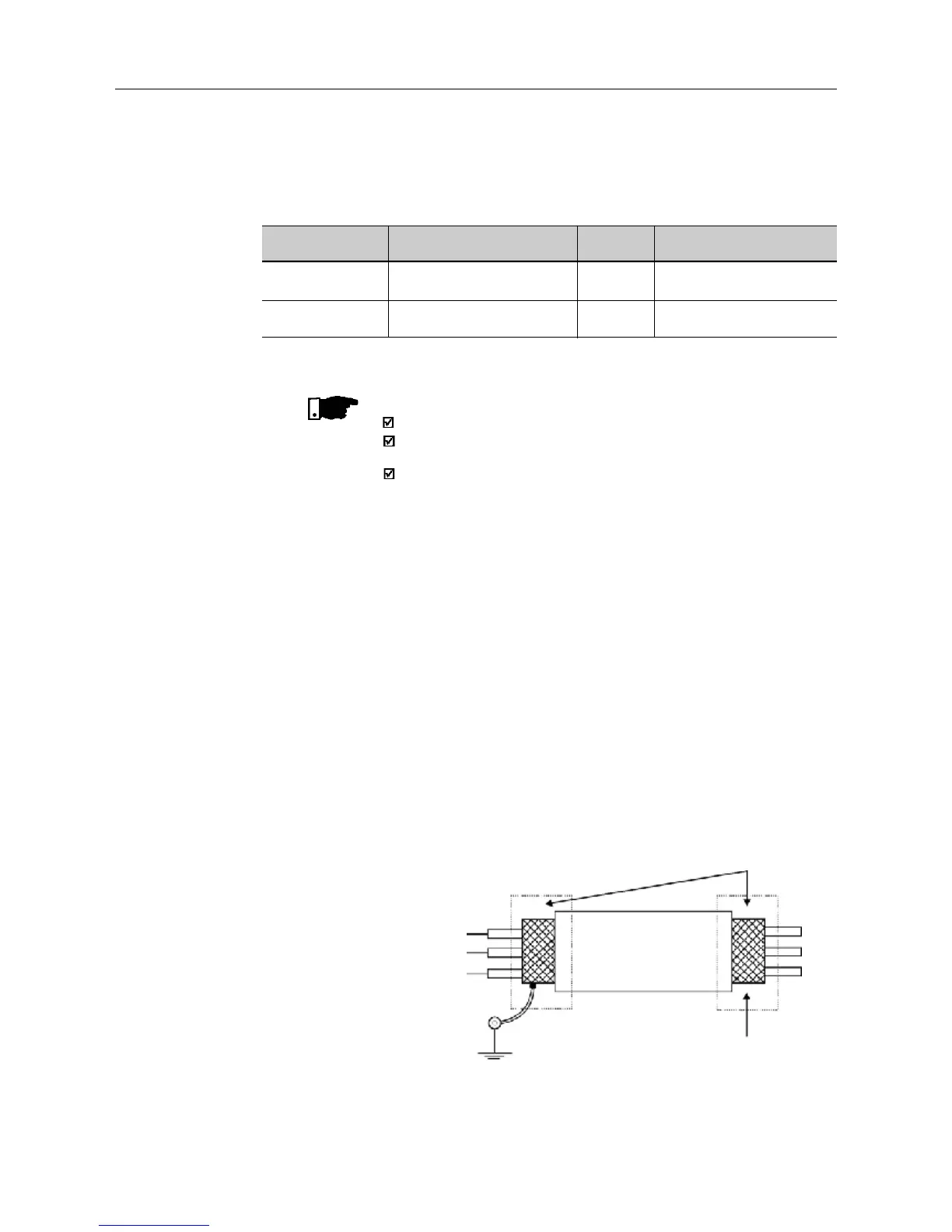

Connect the shield as shown below:

Figure 3.11 - Shield connection

Connect to earth: bolts are located on heatsink

Do not

ground

Inverter

side

Insulate with tape

4) For wiring distances longer than 150 ft ( 50 m), it's necessary to use

galvanic isolators for the XC1:5...9 analog signals.

As a default the analog input(s) is(are) selected as 0...10V. This can be

changed using dip switch S1 on the control board and parameters P235

and P239 (see note below).

Loading...

Loading...