97

DETAILED PARAMETER DESCRIPTION

Range

[Factory Setting]

Parameter Unit Description / Notes

P300 0.0...15.0s

DC Braking [ 0.0 ]

Time 0.1s

P301 0.00...15.00Hz

DC Braking [ 1.00Hz ]

Start Frequency 0.01Hz

P302 0.0...130%

DC Braking [ 0.0% ]

Current 0.1%

The DC braking feature provides a motor fast stop via DC current

injection.

The applied DC braking current, that is proportional to the braking

torque, is set at P302, and is adjusted as a percentage (%)

relating to the rated inverter current.

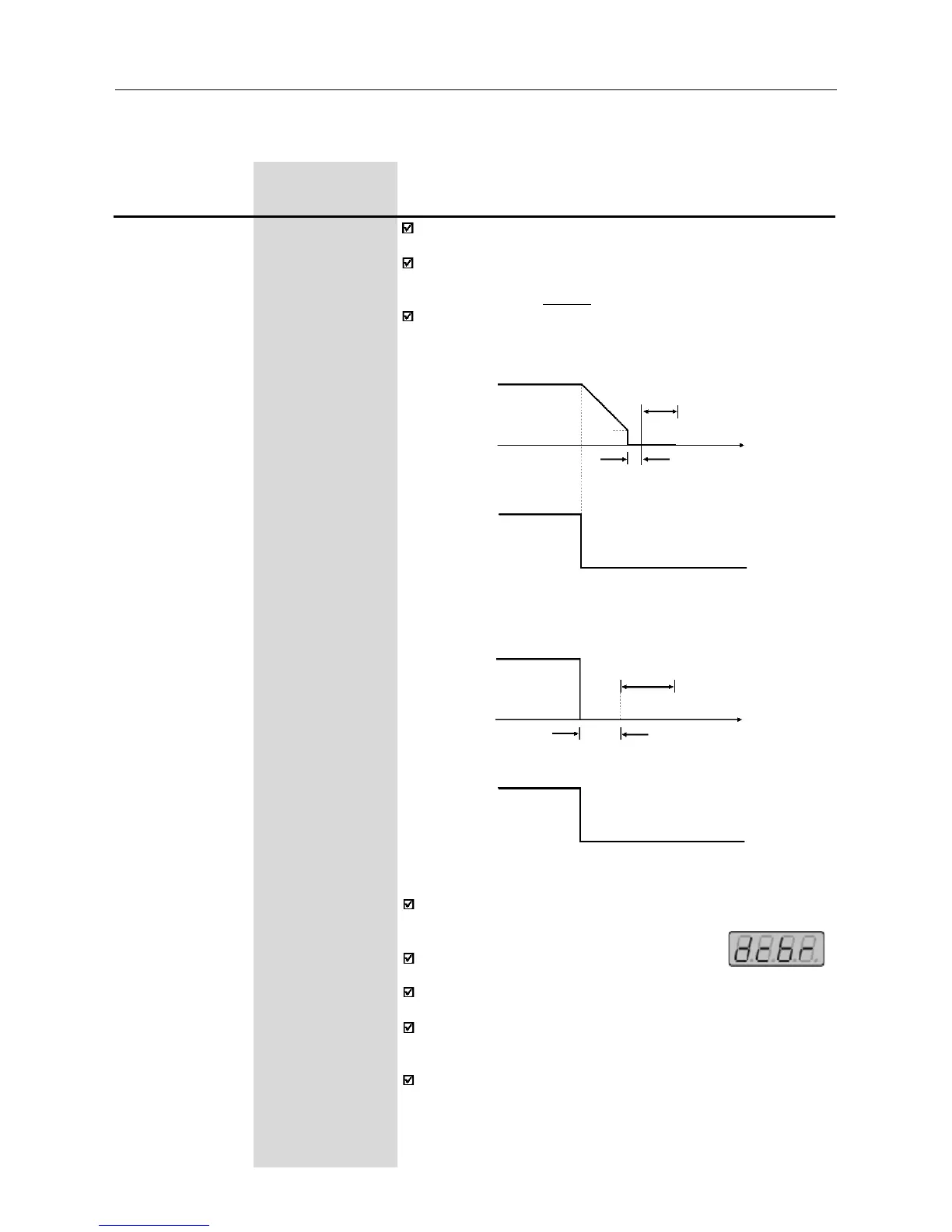

The figures below show the DC branking operation at the two possible

conditions: ramp disabling and general disabling.

P301

P300

DEAD

TIME

open

Time

DI - Start/Stop

0V

DC CURRENT

INJECTION

Figure 6.21 - DC braking after ramp disabling

P300

open

Time

DEAD TIME

DC CURRENT

INJECTION

DI - General Enable

Figure 6.22 - ADC braking after general disabling

Motor Speed

Output Frequency

0V

Before DC braking starts, there is a "Dead Time" (motor runs freely)

required for the motor demagnetization. This time is function of the

motor speed at which the DC braking occurs.

During the DC braking the LED display flashes .

If the inverter is enabled during the braking process, this process

will be aborted and motor operates normally.

DC braking can continue its braking process even after the motor

has stopped. Pay special attention to the dimensioning of the motor

thermal protection for cyclic braking of short times.

In applications where the motor current is lower than the rated

inverter current, and where the braking torque is not enough for

the braking condition, please contact WEG to optimize the

settings.

Motor Speed

Output Frequency

Loading...

Loading...