93

7

MAINTENANCE

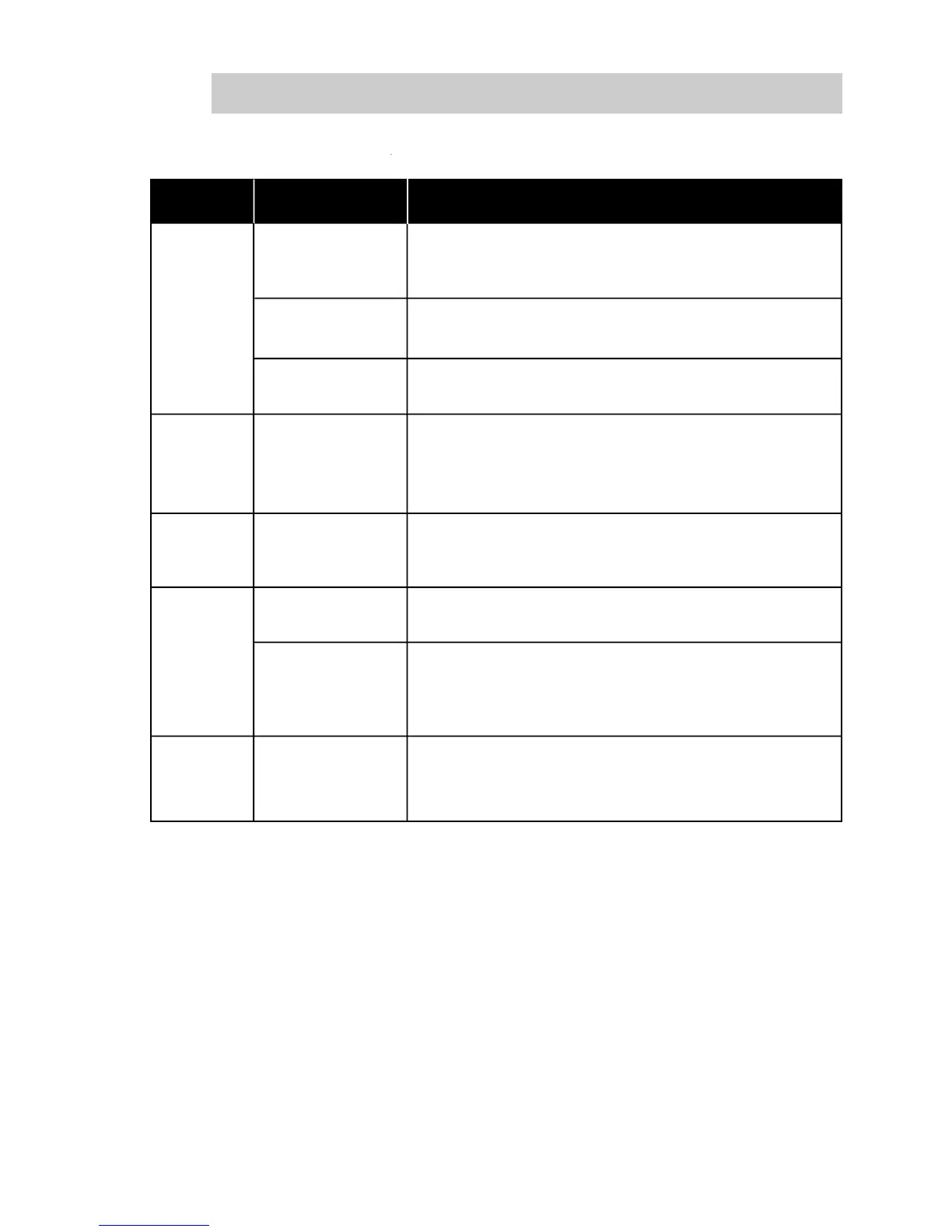

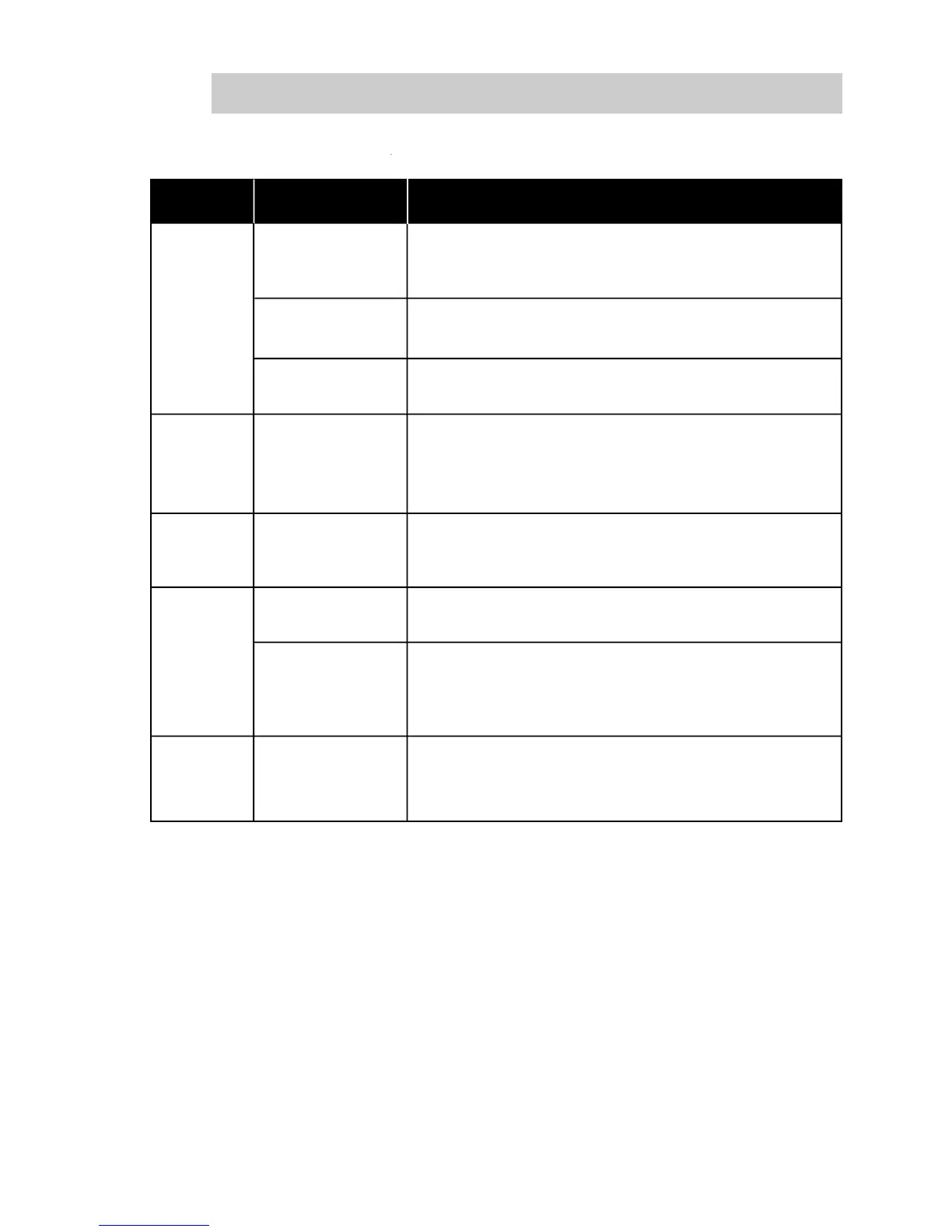

Table 7.2 - Hardware errors and possible solutions

POINT TO BE

CHECKED

PROBLEM

CORRECTIVE ACTION

1. Check all power and control connections. For

instance, check the digital input of extern error that

must be connected to +24V.

1. Check if the parameters are correct programmed

for the application.

1. Check if the Soft-Starter is not disabled due to a

detected error condition (see table above).

1. Disable the Soft-Starter, switch OFF the suplly

voltage and tighten all connections.

2. Check if all intern Soft-Starter connections are

tightened.

1. Check if the motor is used according to its

application

1. Check the HMI connections to the Soft-Starter

(control board CCS3.0X)

1. The rated values must meet the following

requirements: For 220-230Vac For 110-120Vac

- Min.: 187Vac - Min.: 93.5Vac

- Max. 253Vac - Max. 132Vac

1. Decrease the deceleration time setting on the

parameter P04.

Motor does

not run

Motor speed

changes

(oscillates)

Motor speed

too high or

too low

Display OFF

Jerk during

deceleration

Wiring not correct

Wrong

programming

Error

Loose connections

Motor nameplate

data

HMI connections

Check the supply

voltage X1.1 and

X1.2

Soft-Starter

programming

Loading...

Loading...