SERVICING

Piston and Connecting Rod

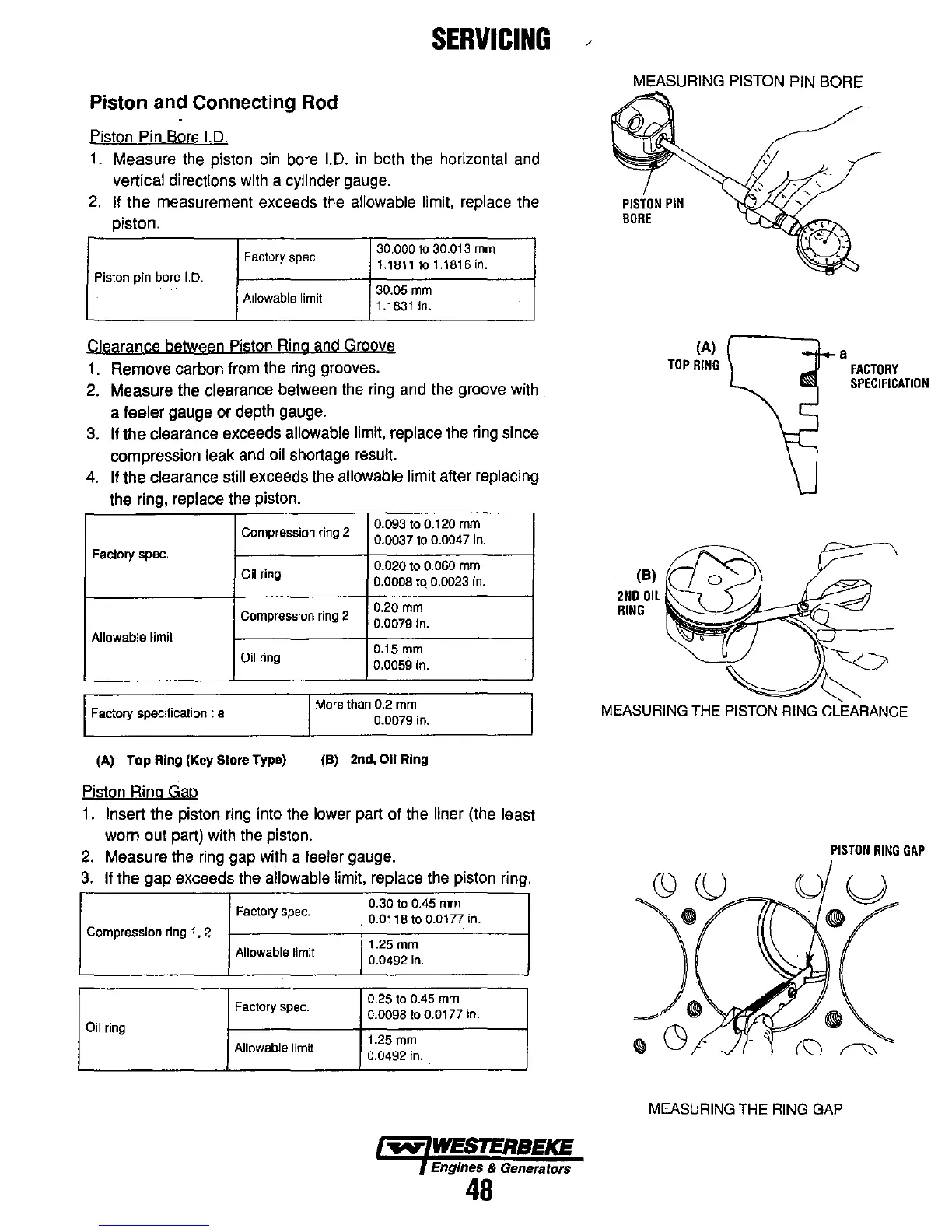

Piston Pin Bore I.D.

1.

Measure the piston

pin

bore I.D.

in

both the horizontal and

vertical directions with a cylinder gauge.

2.

If

the

measurement exceeds the allowable limit, replace the

piston.

Factory

spec.

30.000 to 30.013

mm

1.1811 to 1.1816

in.

Piston

pin

bore

I.D.

Allowable

limit

30.05

mm

1.1831 in.

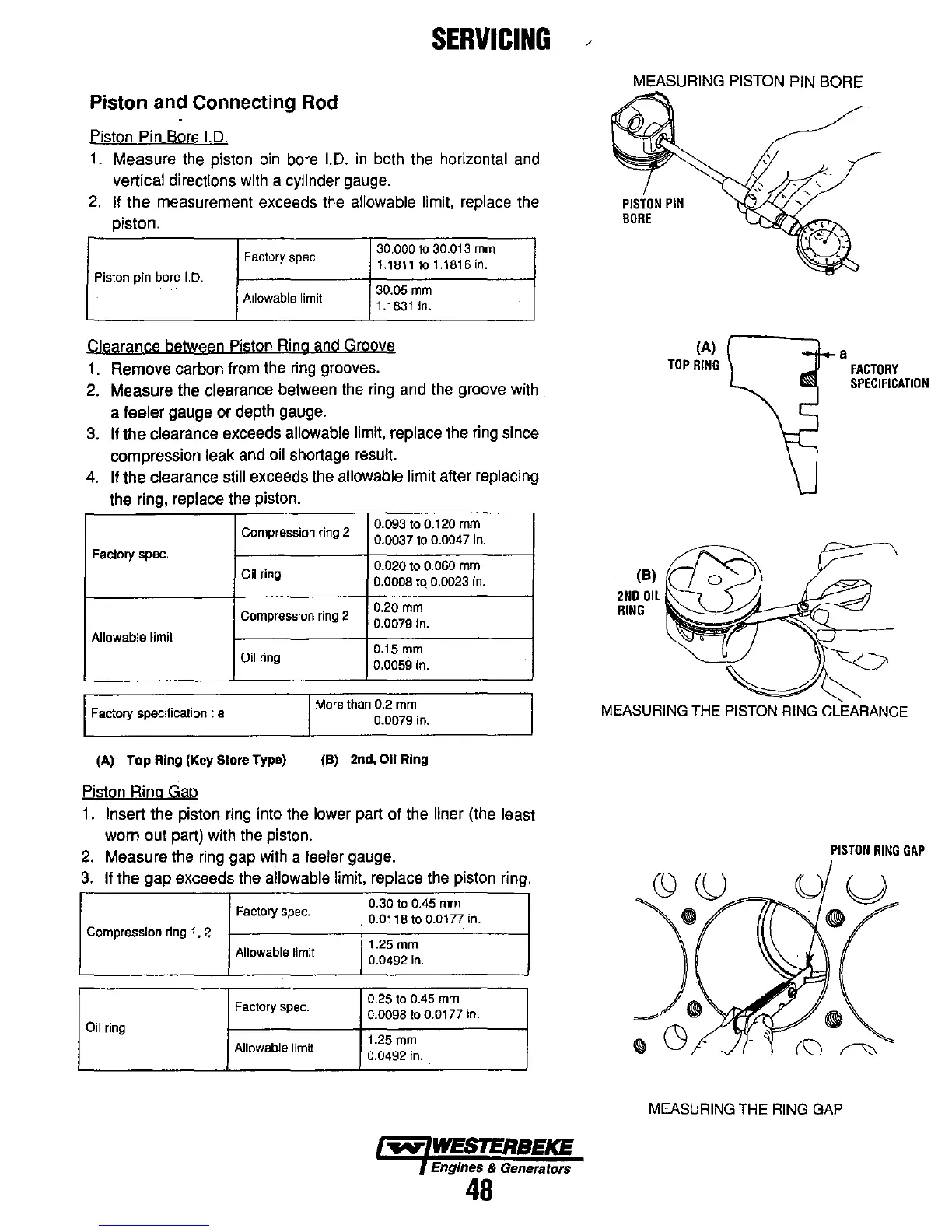

Clearance between Piston Ring and Groove

1.

Remove carbon from the ring grooves.

2.

Measure the clearance between the ring and the groove with

a

feeler gauge or depth gauge.

3.

If

the

clearance exceeds allowable limit, replace the ring since

compression

leak and oil shortage result.

4.

If the clearance still exceeds the allowable limit after replacing

the ring, replace the piston.

Compression

ring

2

0.093 to 0.120 mm

0.0037 to 0.0047 in.

Factory spec.

0.020

to

0.060 mm

Oil

ring

0.0008 tq 0.0023 in.

Compression

ring

2

0.20 mm

0.0079 in.

Allowable limit

Oil

ring

0.15 mm

0.0059 In.

Factory

specification:

8

I More than 0.2 mm

0.0079 in.

(A) Top

Ring

(Key

Store

Type)

(B) 2nd,

011

Ring

Piston Ring Gap

1.

Insert the piston ring into the lower part of the liner (the least

worn out part) with the piston.

2.

Measure the ring gap with a feeler gauge.

3.

If the gap exceeds the allowable limit, replace the piston ring.

Factory

spec.

0.30 to 0.45

mm

O.Ot

18 to 0.0177 in.

Compression

ring

1 . 2

Allowable

limit

1.25

mm

0.0492

in.

Factory

spec.

0.25 to 0.45

mm

0.0098 to 0.0177 in.

Oil

ring

Allowable

limit

1.25

mm

0.0492

in.

...v

WESTERBEKE

Engines & Generators

48

MEASURING

PISTON

PIN

BORE

I

PISTON

PIN

BORE

(A)

TOP

RING

a

FACTORY

SPECIFICATION

MEASURING THE PISTON RING CLEARANCE

PISTON

RING

GAP

MEASURING THE RING GAP

Loading...

Loading...