en Commissioning

74 WILO SE 2019-07

Menu 2: ModBus field bus connection

The switchgear is equipped with an RS485 interface for connection via ModBus RTU.

Different parameters can be read and also changed to some extent via the interface. In

this case, the switchgear works as a Modbus slave. An overview of individual parameters

and a description of the data types used are shown in the appendix. To use the ModBus

interface, the settings must be changed in the following menus:

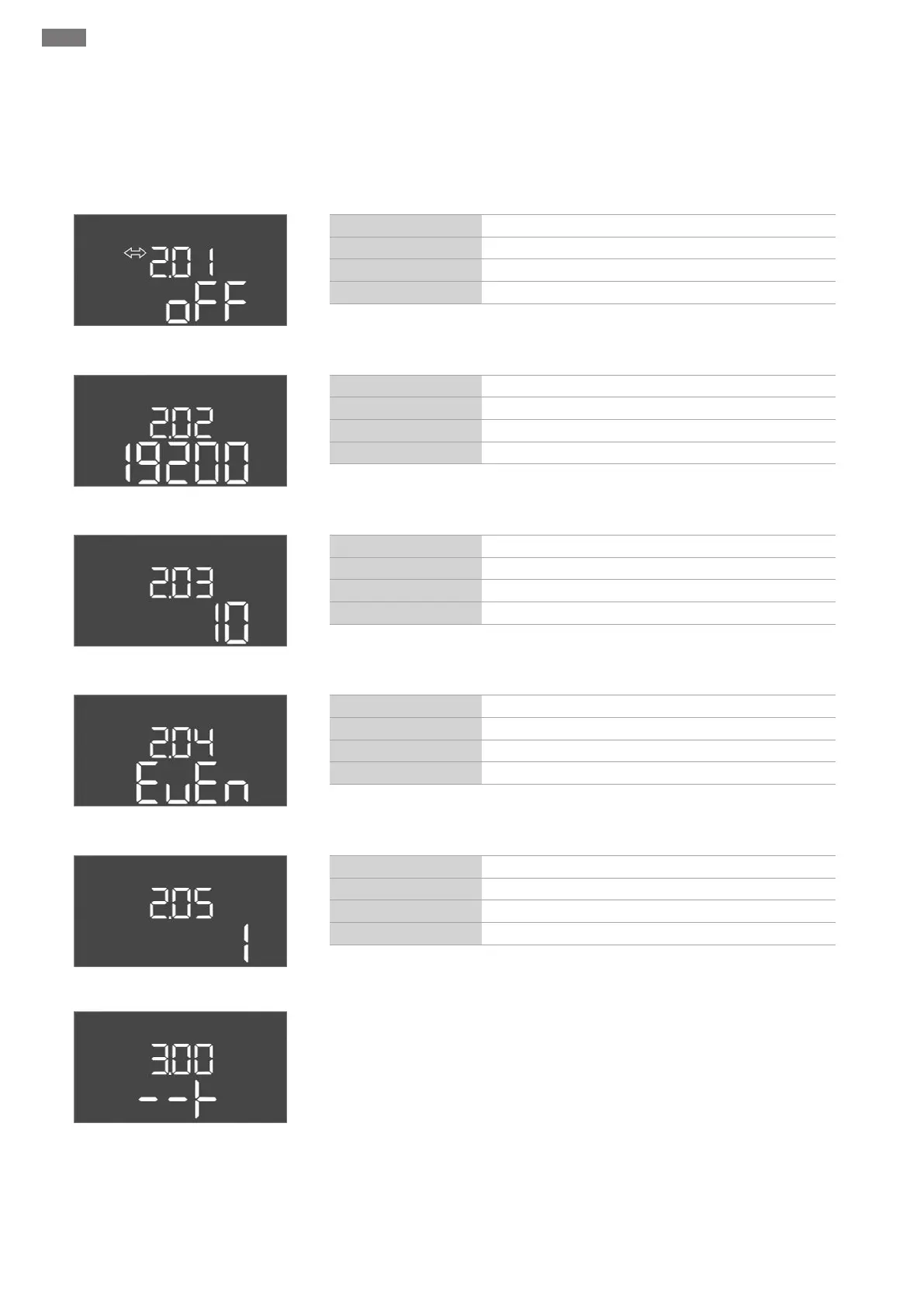

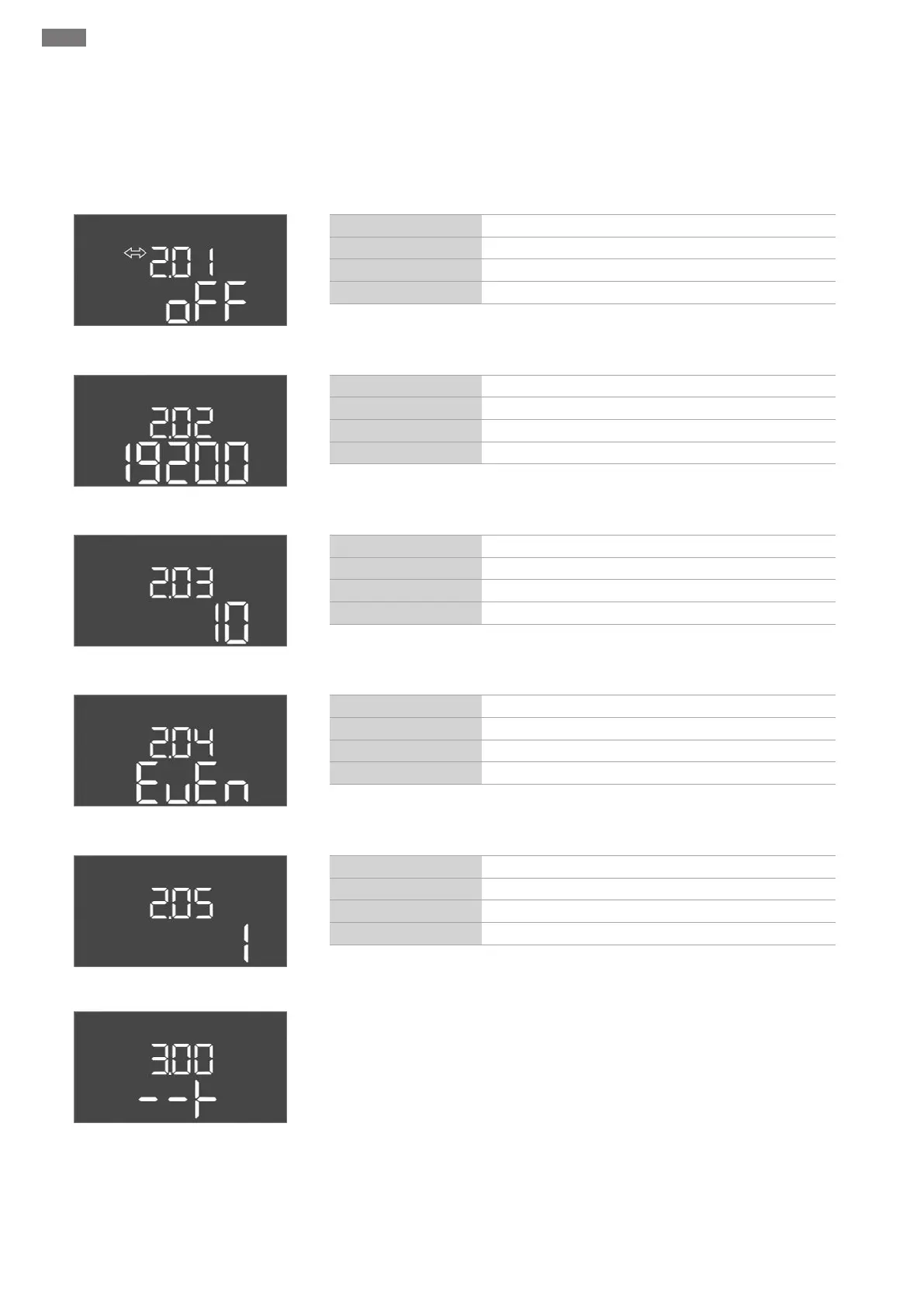

Fig.59: Menu 2.01

Menu no. 2.01

Description ModBus RTU interface On/Off

Value range on, off

Factory setting off

Fig.60: Menu 2.02

Menu no. 2.02

Description Baud rate

Value range 9600; 19200; 38400; 76800

Factory setting 19200

Fig.61: Menu 2.03

Menu no. 2.03

Description Slave address

Value range 1 … 254

Factory setting 10

Fig.62: Menu 2.04

Menu no. 2.04

Description Parity

Value range none, even, odd

Factory setting even

Fig.63: Menu 2.05

Menu no. 2.05

Description Number of stop bits

Value range 1; 2

Factory setting 1

Menu 3: Enable pumps

To operate the system, the operating mode must be set for each pump and the pumps

enabled:

▪Every pump is set to the “auto” operating mode as the factory setting.

▪Automatic mode starts after the pumps have been enabled in menu 3.01.

NOTICE!Required settings for the initial configuration.

Carry out the following work during initial configuration:

▪Check direction of rotation of the pumps

▪Set precise motor current monitoring (“Control EC-Booster” only)

Use the following settings to perform the initial configuration:

Loading...

Loading...