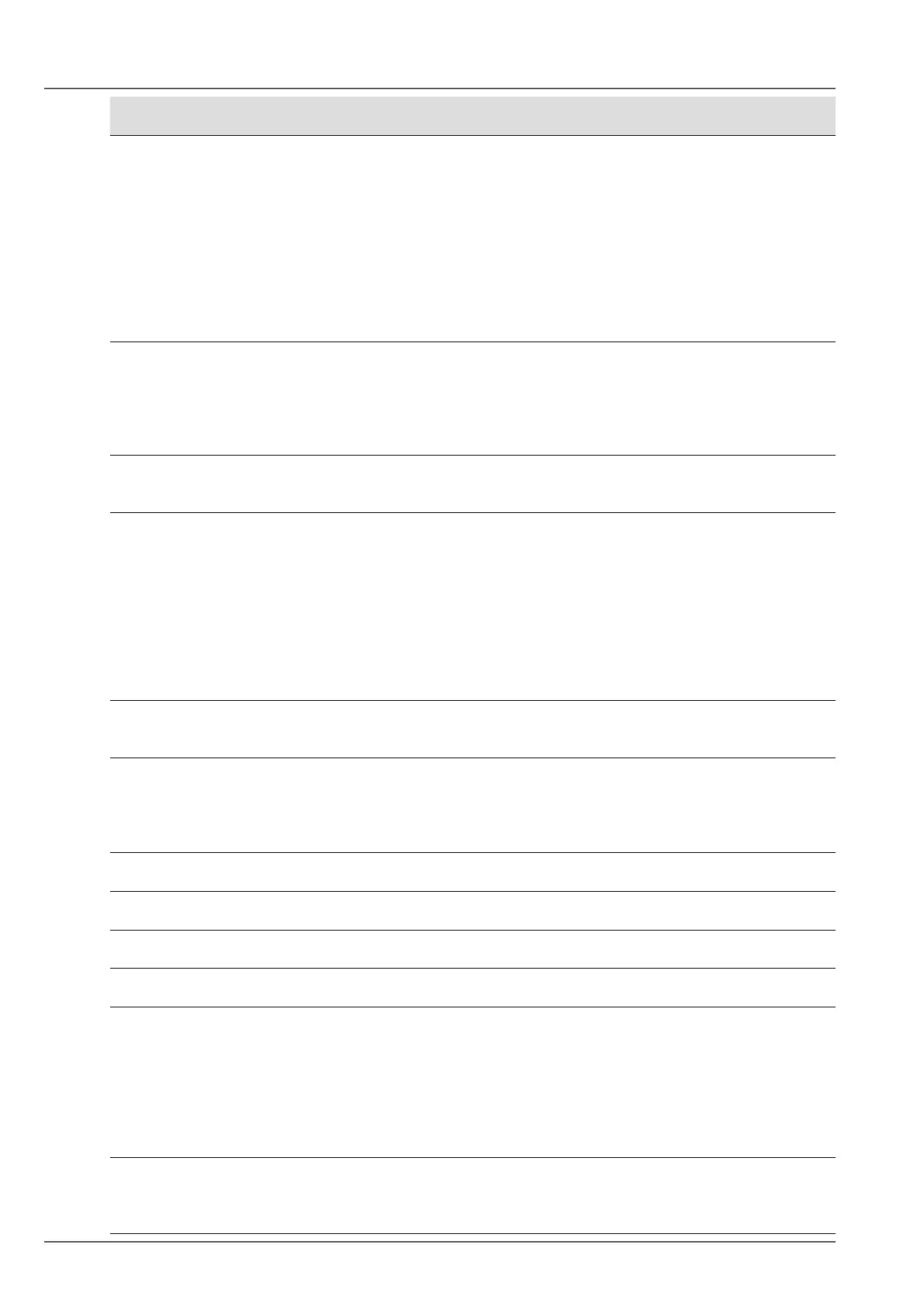

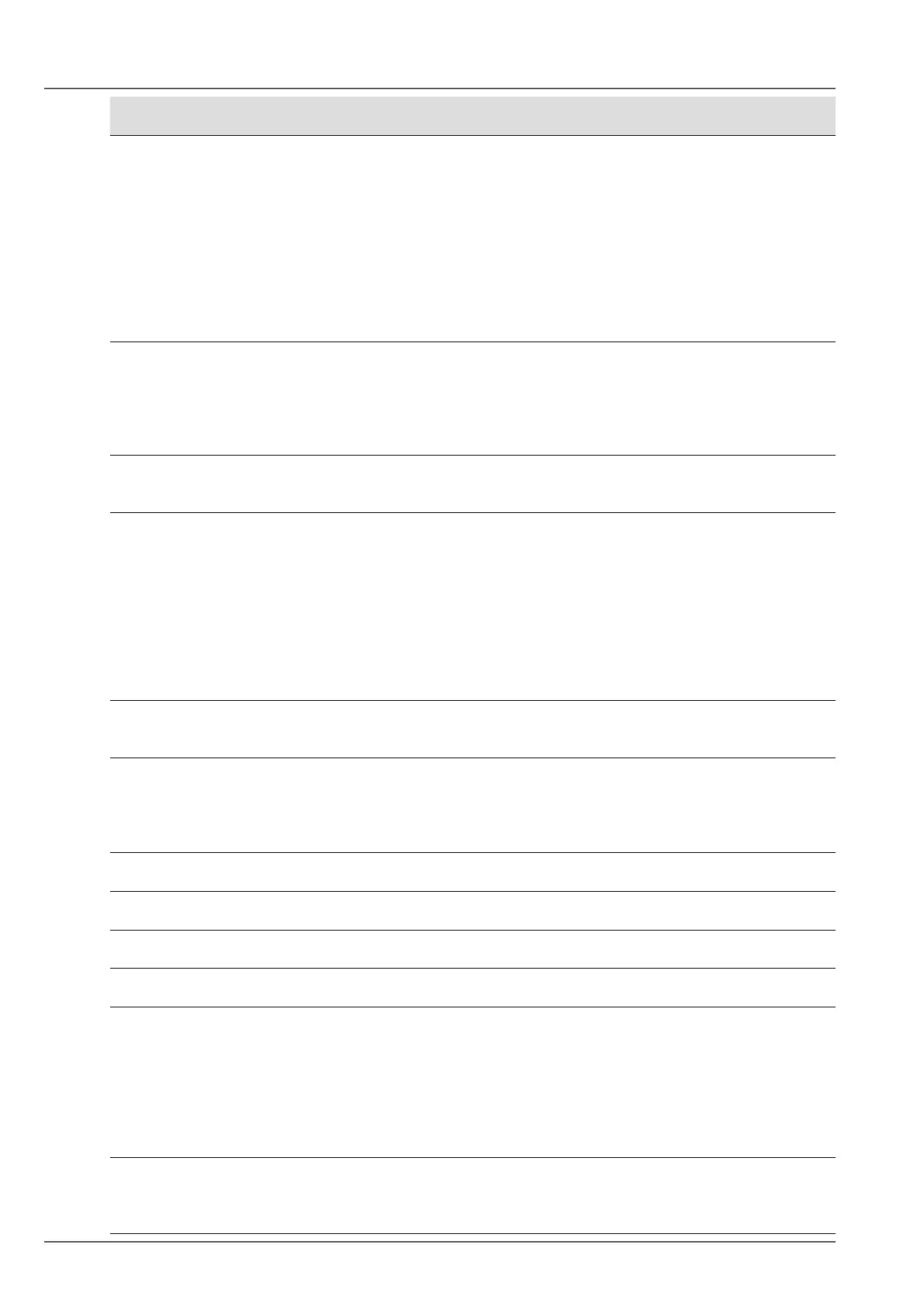

Fault

66 | WOLF GmbH 3066501_201910

Fault

code

Message Cause Remedy

4 No ame – When the burner starts, no ame

forms by the end of safety time.

– Ignition electrodes contaminated.

– Air in the oil feed line.

– Heat generator contaminated.

► Check oil line, check oil level,

if necessary.

► Check ignition electrodes and

ignition transformer.

► Check solenoid valve for oil

pump.

► Check that the condensate

can drain off freely.

► Press reset button.

► Check CO

2

values.

► Service the equipment.

5 Flame failure – Flame failure during operation.

– Flue gas return system (ue gas

in the supply air).

– Air in the oil feed line.

– Heat generator contaminated.

► Check ue system for leaks.

► Check oil line, check oil level,

if necessary.

► Press reset button.

► Check CO

2

values.

► Service the equipment.

6 Temperature limiter,

excess temperature

– The ow has exceeded the limit of

the temperature limiter (95°C).

► Vent the system.

► Check the heating circuit

pump.

7 Flue gas sensor,

excess temperature

– The ue gas temperature has

exceeded 120°C.

► Clean the heating water heat

exchanger.

► Check that all displacement

devices are properly installed.

► Check the ow through the

heat generator.

► Check that the heating ow

and return are connected

correctly.

► Press reset button.

8 Flue gas/supply air

damper does not

respond

– Flue gas/supply air damper

contact (E1) fails to close or open

when there is a demand.

► Check wiring of ue gas/supply

air damper.

11 False ame – A ame is recognised before the

burner starts.

► Check solenoid valve for oil

pump.

► Check ignition electrodes and

ignition transformer.

► Press reset button.

12 Boiler sensor faulty – Faulty boiler sensor or lead. ► Check sensor.

► Check lead.

13 Flue gas sensor faulty – Faulty ue gas sensor or lead. ► Check sensor.

► Check lead.

14 Faulty cylinder sensor

CS

– Faulty cylinder sensor or lead. ► Check sensor.

► Check lead.

15 Outside temperature

sensor fault

– Faulty outside temperature sensor

or lead.

► Check sensor.

► Check lead.

22 Differential pressure

sensor not responding

– Supply air or ue gas path

blocked.

– Differential pressure too low in

pre-purge phase.

– Differential pressure sensor or

cable defective.

– Air ducts not connected or

incorrectly connected.

► Check supply air and ue gas

path.

► Check differential pressure

sensor.

► Check lead.

► Check air ducts.

23 Differential

pressure sensor not

deactivating

– Differential pressure sensor fails

to switch back.

– Inltrating air owing through the

heat generator.

► Check differential pressure

sensor.

Loading...

Loading...