Do you have a question about the Xantrex XDC and is the answer not in the manual?

Details the scope and length of the product's warranty coverage.

Explains Xantrex's procedures for repair or replacement of defective products.

Provides contact information and steps for initiating warranty service.

Lists specific conditions and damages excluded from warranty coverage.

Legal disclaimer regarding warranty terms and liabilities.

Provides critical usage guidelines and limitations for the product.

Outlines critical safety precautions for power supply operation.

Lists the certifications and standards the product meets.

Explains how to locate information within the manual.

Introduces the XDC series power supplies and their applications.

Lists the key capabilities and functionalities of the XDC series.

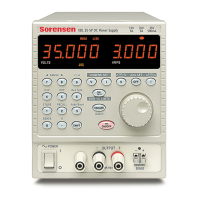

Visual representation of the 6000 Watt model's front panel.

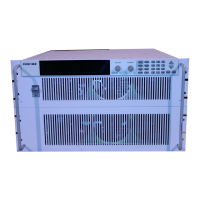

Visual representation of the 12000 Watt model's front panel.

Explains the purpose of each key on the front panel keypad.

Visual representation of the front panel display.

Explains the meaning of the various status indicators on the front panel.

Visual representation of the rear panel connectors.

Introduces the installation procedures and recommendations.

Outlines the essential steps for setting up the power supply.

Covers initial inspection, cleaning, and routine maintenance of the power supply.

Explains the requirements for returning products for service.

Provides instructions on how to properly pack the power supply.

Specific instructions for installing the unit in a standard equipment rack.

Specifies the necessary airflow and spacing for proper cooling.

Describes the AC input connector and its configuration.

Lists the recommended wire types and specifications for AC input.

Provides step-by-step instructions for connecting AC input wires for 6000W units.

Provides step-by-step instructions for connecting AC input wires for 12000W units.

Lists the necessary tools for performing basic checks.

Describes how to test the front panel display.

Steps to verify correct power-on sequence and initial status.

Procedure to test the power supply in voltage regulation mode.

Procedure to test the power supply in current regulation mode.

Details recommended wire sizes based on current requirements.

Covers guidelines for load wiring length and minimizing noise and impedance.

Specific guidance on selecting appropriate wire gauges.

Specifies insulation requirements for output wiring.

Step-by-step instructions for connecting a single load.

Instructions for connecting multiple loads in parallel.

Explains how to use remote sensing for improved load regulation.

Introduces the operational aspects of the power supply.

Step-by-step guide to turning the unit on.

Describes the different operational states of the power supply.

Explains the different modes of operation (CV, CC, CP) and automatic crossover.

Details the procedure for safely shutting down the power supply.

Describes the various interfaces available for remote operation.

Introduces the front panel controls used for operating the power supply.

Explains the function of each key on the front panel.

Lists the main menu options available.

Details the function and operation of the front panel control knobs.

Step-by-step instructions for setting the voltage.

Step-by-step instructions for setting the current.

Instructions for setting the power limit.

Explains how to enable and disable the power supply output.

Details how to configure various protection mechanisms.

Describes additional protection features like AC Off and Over Temperature.

Step-by-step guide for configuring OVP settings.

Guides for configuring UVP and OCP.

Guides for configuring UCP and OPP.

Guides for configuring UPP and Fold Protection.

Details on configuring Fold Protection and recovery options for AC Off/OTP.

How to manage alarms and respond to shutdown events.

Differentiates between shutdown and alarm conditions.

How to switch between front panel and remote control modes.

Procedure for saving custom power supply configurations.

How to modify or overwrite saved user settings.

How to retrieve saved configurations or auto-sequence programs.

Procedure for viewing and clearing error messages for troubleshooting.

How to set up auxiliary lines for status reporting.

Details on how the power supply behaves upon power-up.

Restoring the power supply to its original factory settings at startup.

Explains how to select and run stored auto-sequence programs.

Restoring a saved custom setting upon power-on.

Restoring settings from the last power-off state upon power-on.

Detailed steps for creating and programming automated sequences.

Step-by-step guide for programming sequence steps.

How to define time-based transitions between sequence steps.

How to define trigger-based transitions between sequence steps.

Procedure for removing an entire programmed sequence.

How to modify individual steps within a programmed sequence.

How to add a new step into an existing programmed sequence.

How to remove a specific step from a sequence.

How to configure how many times a sequence will repeat.

How to select the source for sequence triggers.

How to run and manage auto-sequence programs.

How to customize the front panel display.

How to disable front panel knobs to prevent accidental changes.

How to configure protection limits for output parameters.

How to adjust the output voltage slew rate.

Details on setting slew rate parameters.

How to view device information and monitor status.

Introduces the remote control capabilities.

Lists common commands supported by the device.

Illustration of connection ports for remote interfaces.

Details the analog interface ports and their pin functions.

How to set up analog programming parameters (range, control).

Choosing the desired interface for remote operation.

Procedures for operating the supply via analog signals.

Describes physical connections and CANbus interface.

SCPI commands for setting up multichannel addressing.

How to operate the system once configured.

Specific SCPI commands for controlling multichannel systems.

How to send commands to all units simultaneously.

Details on the RS-232 port and its pinout.

Steps to set RS-232 baud rate and flow control.

SCPI commands for RS-232 communication.

How to send commands via RS-232.

Details on the GPIB port and its pinout.

Steps to set GPIB address and service request.

SCPI commands for GPIB communication.

How to send commands via GPIB.

SCPI commands for configuring power-on behavior.

SCPI for recalling last, user, and auto-sequence settings.

SCPI for setting power-on output state.

SCPI command for resetting the unit.

Table showing reset behavior.

SCPI commands for saving settings.

SCPI for switching control modes.

SCPI commands to control output state.

SCPI commands for setting voltage, current, and power.

More SCPI commands for setting voltage, current, and power.

SCPI commands to set protection parameters.

More SCPI commands for protection limits.

SCPI for fold protection configuration.

SCPI for OTP and AC Off settings.

SCPI to clear protection events.

SCPI to query output values.

SCPI to configure auxiliary lines.

More SCPI commands for auxiliary status lines.

SCPI to read error messages.

SCPI for programming triggers.

SCPI for programming auto sequences.

SCPI for managing auto sequence operation and editing.

SCPI for programming sequence steps.

SCPI for selecting trigger sources.

SCPI for editing sequence step parameters.

SCPI for deleting sequences.

SCPI for controlling auto sequence execution.

SCPI for adjusting slew rate.

SCPI for identifying the device.

Explanation of status registers.

Details on the operation status register.

Table of bits for the operation status register.

SCPI for regulating sub-register.

SCPI for shutdown sub-register.

SCPI for protection shutdown.

SCPI for remote control status.

SCPI for current share status.

Explanation of the questionable status register.

SCPI commands for voltage, current, and power sub-registers.

SCPI for temperature sub-register.

Explanation of the standard event status register.

Table of bits for the standard event status register.

Explanation of status byte and error queue.

SCPI command to preset status registers.

Commands related to IEEE 488.2 status.

SCPI for service request enable and parallel poll enable.

SCPI for status byte and operation complete.

SCPI for operating status registers.

SCPI for regulating sub-registers.

SCPI for shutdown sub-registers.

SCPI for protection shutdown.

SCPI for remote control status.

SCPI for current share status.

SCPI for questionable status registers.

SCPI for voltage sub-registers.

SCPI for current sub-registers.

SCPI for power sub-registers.

SCPI for temperature sub-registers.

Introduces the current sharing feature for 6000W units.

Explains the principle behind current sharing between units.

Step-by-step guide for front panel current sharing setup.

SCPI commands and physical setup for current sharing networks.

How to operate the current sharing network and troubleshoot common errors.

Technical specifications for the current sharing feature.

Introduces the unit's software-dependent calibration process.

Procedures for accessing the calibration menu.

Steps to enter calibration mode using the front panel.

SCPI commands to enter and manage calibration mode.

Step-by-step guide for front panel calibration.

How to change the calibration security code.

Lists necessary equipment and setup for calibration.

Detailed steps for calibrating output voltage via the front panel.

Detailed steps for calibrating output current via the front panel.

Steps for calibrating the 0-5V analog interface.

Details for calibrating analog voltage readback and current programming.

Details for calibrating analog current readback.

Steps for calibrating output voltage remotely.

Steps for calibrating output current remotely.

Remote calibration for the 0-5V analog interface.

Remote calibration for the 0-10V analog interface.

Procedure to revert calibration to factory defaults.

Introduces the SCPI command set.

Lists standards the SCPI implementation follows.

Details on SCPI parameter syntax and units.

Describes the structure and organization of SCPI commands.

Guidelines and best practices for sending SCPI commands.

Covers command syntax, min/max values, queries, terminators, and common commands.

Explains different data types used in SCPI commands (Boolean, Discrete, Numeric, String).

Overview of SCPI commands and abbreviations used in tables.

Table listing IEEE 488.2 commands.

Table listing SCPI commands for reading values.

Table of SCPI commands related to output control.

Table of SCPI commands specific to current sharing.

Table of SCPI commands for calibration procedures.

Table of SCPI commands for protection mechanisms.

Table of SCPI commands for managing status registers.

More SCPI commands for status registers.

More SCPI commands for status registers.

More SCPI commands for status registers.

SCPI for protection and auxiliary line configuration.

Table of SCPI commands for programming auto sequences.

More SCPI commands for auto sequence management.

Explains how errors are managed and queued.

Lists and describes command and execution errors.

Details errors related to parameters, settings, and memory.

Lists and describes device-specific errors.

Lists query errors, user requests, and operation complete events.

Error codes specific to front panel, CPU, analog, and auto sequencing.

Error codes related to CANbus and multichannel operation.

Lists error codes specific to current sharing functionality.

Introduces the GPIB interface and its compliance.

Details multiline control and interface functions for GPIB.

Covers driver requirements, electrical, and performance specs for GPIB.

General notes and disclaimers regarding specifications.

Covers operating conditions like altitude, temperature, and humidity.

Detailed electrical specs for specific 6000W models.

Drift characteristics for 6000W models.

Detailed electrical specs for specific 6000W models.

Drift characteristics for 6000W models.

Detailed electrical specs for specific 12000W models.

Drift characteristics for 12000W models.

Detailed electrical specs for specific 12000W models.

Drift characteristics for 12000W models.

Details input voltage, frequency, and current requirements.

Defines output capabilities and efficiency ratings.

Performance metrics for output stability under varying loads/voltages.

Specifies the programmable ranges for output parameters.

Details typical programming and measurement resolution and accuracy.

Specifies the accuracy of output readback values.

Details output drift over time.

How output parameters change with temperature.

Impedance characteristics of the analog interface.

Details on auxiliary lines and switching frequency.

Specifications for output voltage transition times.

Information on output stability after changes and power interruptions.

How the output responds to load changes and mode transitions.

Specifications for noise and remote sense features.

Electrical isolation specifications.

Details operating and storage temperature ranges.

Specifies operating and storage humidity limits.

Lists certifications obtained by the product.

Details the physical characteristics of the power supply.

Illustration of the 6000 Watt unit's physical dimensions.

Illustration of the 12000 Watt unit's physical dimensions.

| Brand | Xantrex |

|---|---|

| Model | XDC |

| Category | Power Supply |

| Language | English |

Loading...

Loading...