60C5D11

5-30

1

2

3

4

5

6

7

8

9

CAUTION:

Do not over cut the valve seat. Be sure to

turn the cutter evenly downward at a pres-

sure of 40–50 N (4–5 kgf, 8.8–11 lbf) to

prevent chatter marks.

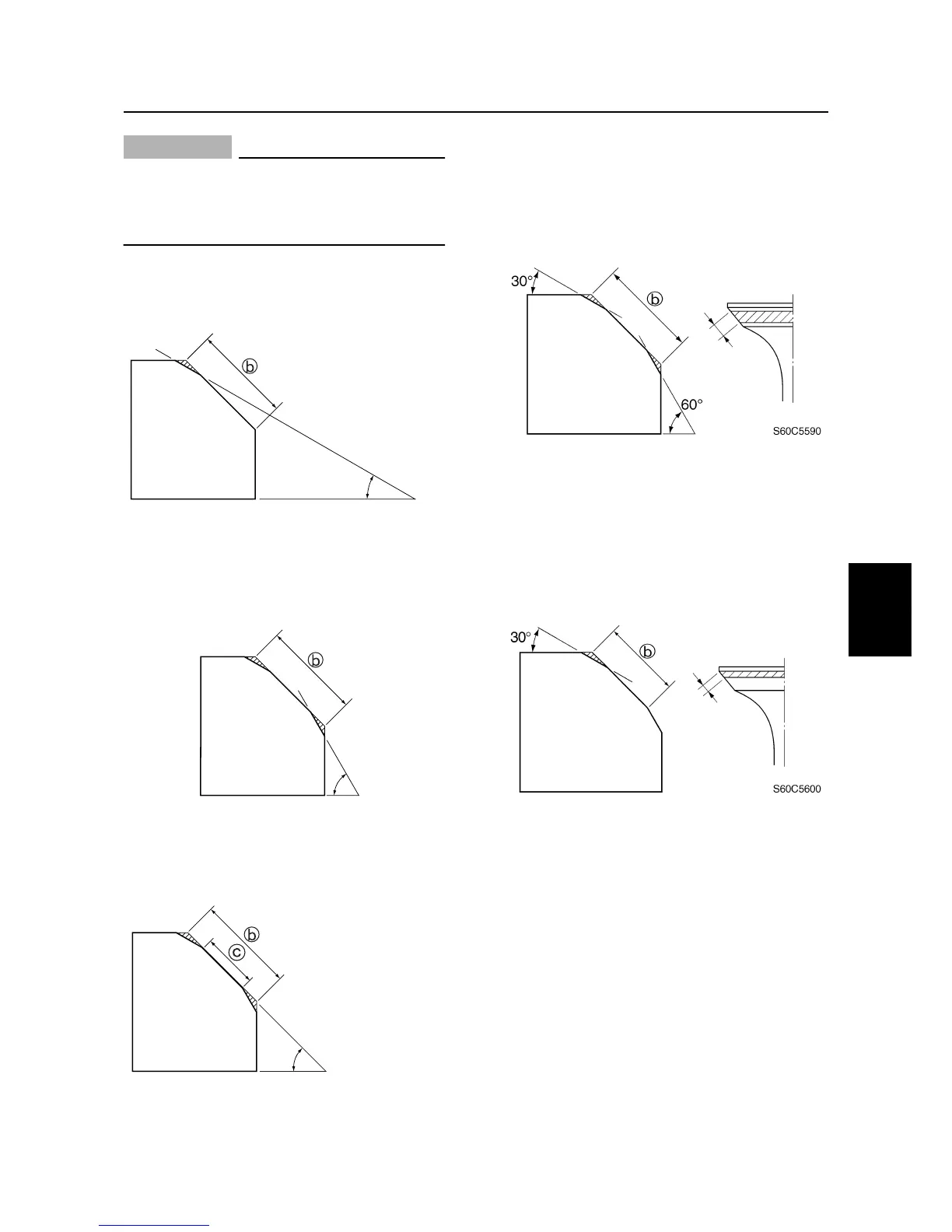

3. Use a 30° cutter to adjust the contact

width of the top edge of the valve seat.

b

Previous contact width

4. Use a 60° cutter to adjust the contact

width of the bottom edge of the valve

seat.

b

Previous contact width

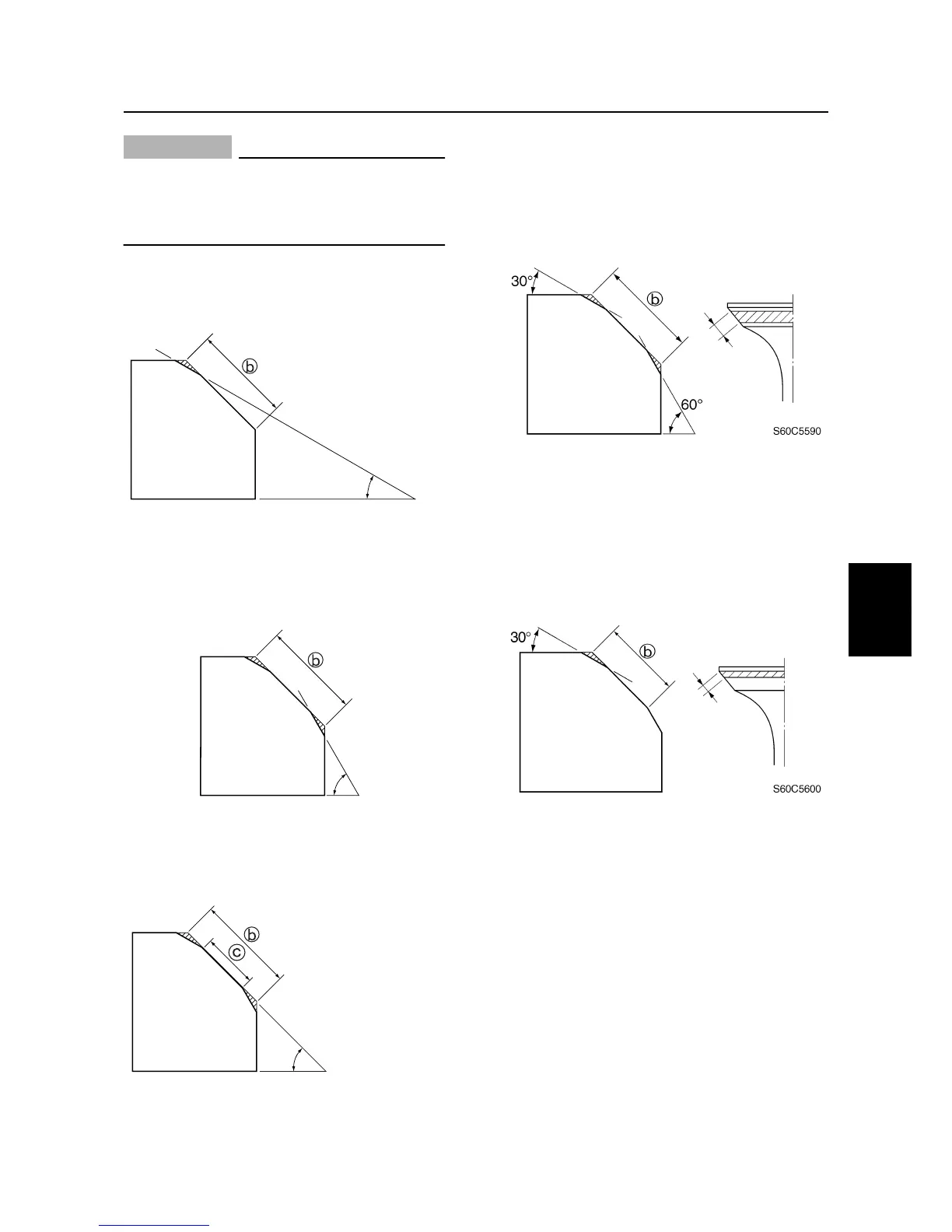

5. Use a 45° cutter to adjust the contact

width of the valve seat to specification.

b

Previous contact width

c

Specified contact width

6. If the valve seat contact area is too wide

and situated in the center of the valve

face, use a 30° cutter to cut the top edge

of the valve seat, a 60° cutter to cut the

bottom edge to center the area and set

its width.

b

Previous contact width

7. If the valve seat contact area is too nar-

row and situated near the top edge of the

valve face, use a 30° cutter to cut the top

edge of the valve seat. If necessary, use

a 45° cutter to center the area and set its

width.

b

Previous contact width

S60C5560

30°

S60C5570

60°

S60C5580

45°

Cylinder head

Loading...

Loading...