60C5D11

5-50

1

2

3

4

5

6

7

8

9

NOTE:

• Make sure that the large, flat side

c

of the

connecting rod faces towards the flywheel

magnet side of the crankshaft.

• Apply engine oil to the connecting rod cap

and connecting rod bolt.

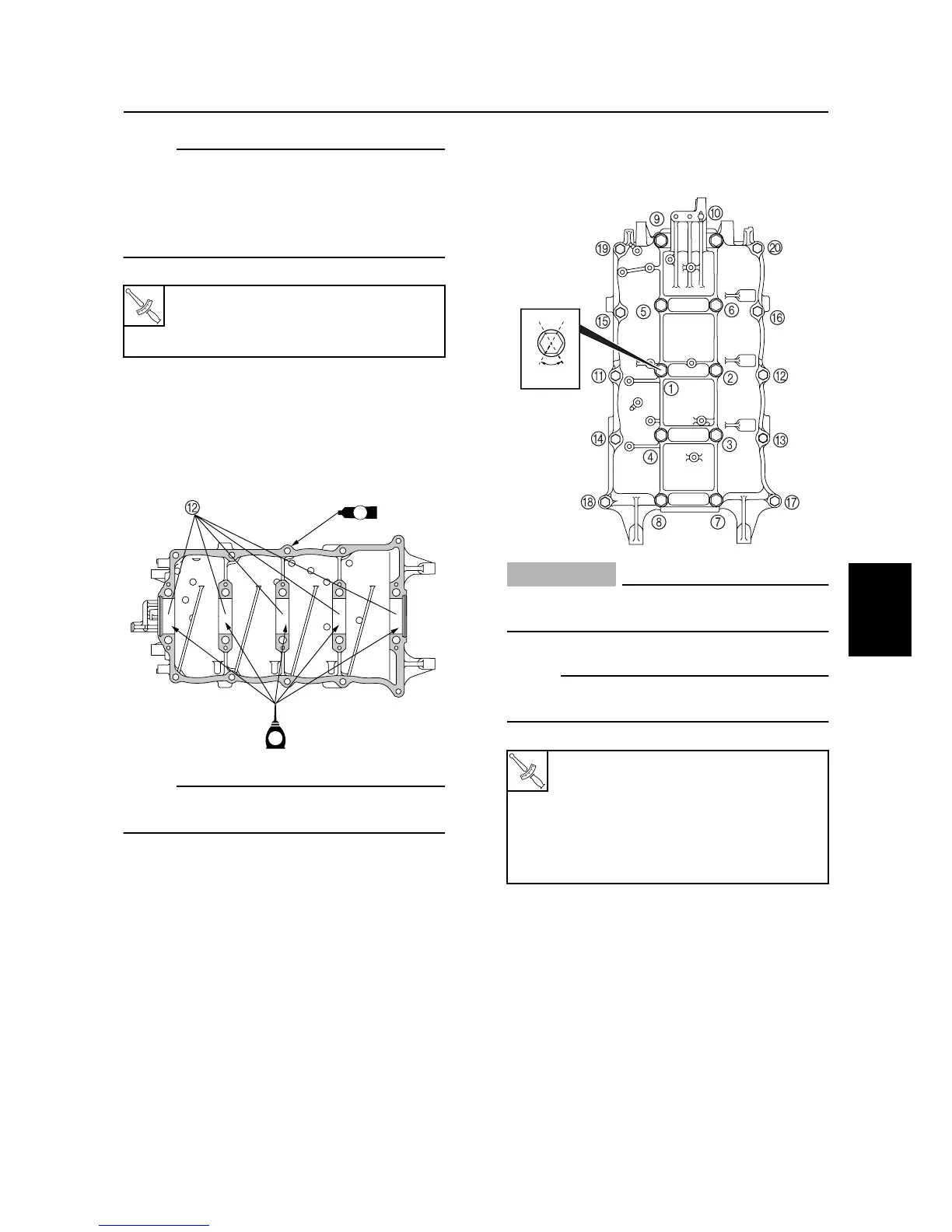

8. Install half of the bearings (plain bear-

ings)

B

into the crankcase.

9. Apply Gasket Maker

®

to the mating sur-

face of the crankcase.

NOTE:

Do not get any Gasket Maker on the journal

bearings.

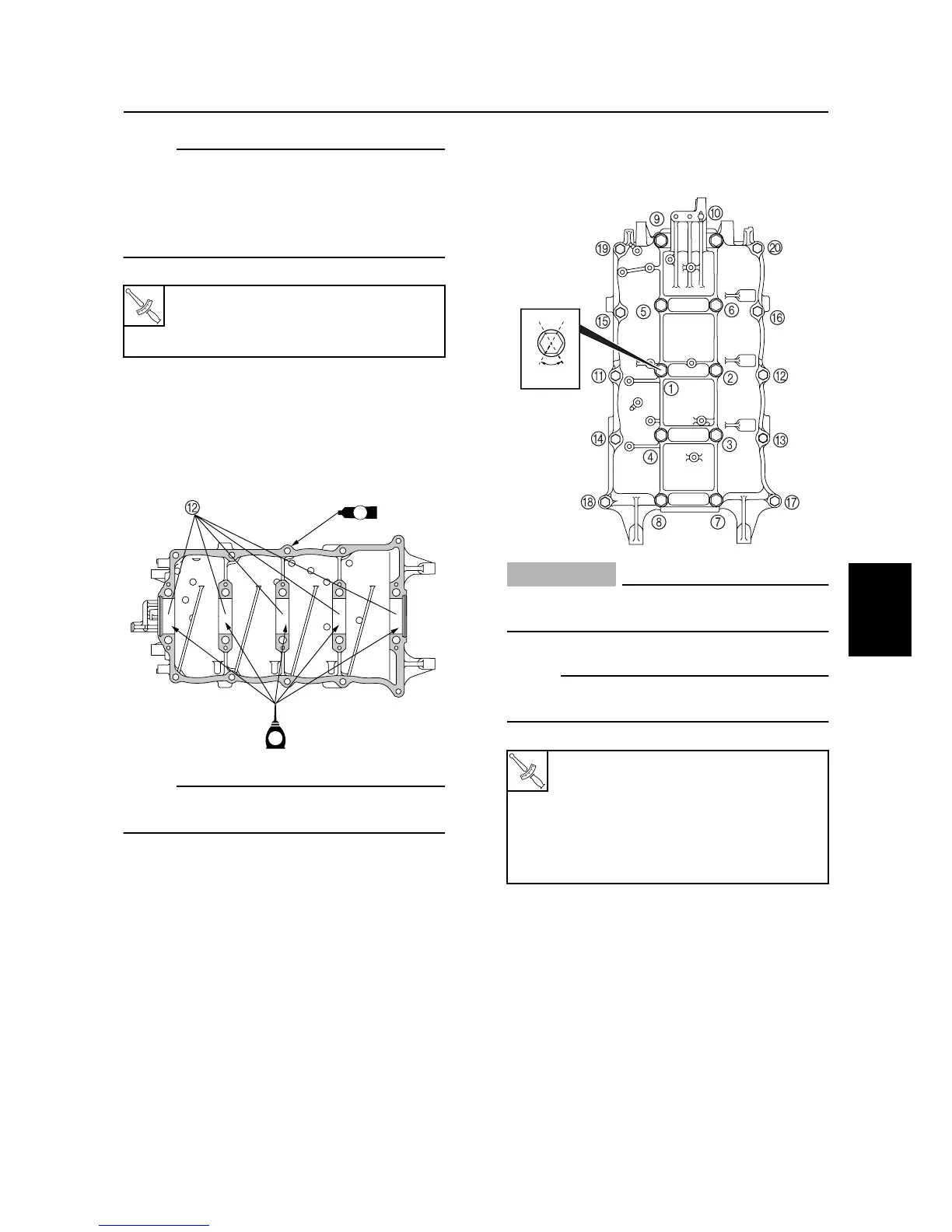

10. Install the crankcase bolts, and then

tighten them to the specified torques in

two stages and in the sequence shown.

CAUTION:

The oil seals must be installed before

tightening the crankcase bolts.

NOTE:

Apply engine oil to the crankcase bolts before

installation.

T

R

.

.

Connecting rod bolt

A

:

1st: 18 N·m (1.8 kgf·m, 13 ft·lb)

2nd: 90°

S60C5B40

E

GM

GM

Crankcase bolt (M10):

1st: 19 N·m (1.9 kgf·m, 14 ft·lb)

2nd: 60°

Crankcase bolt (M8):

1st: 14 N·m (1.4 kgf·m, 10 ft·lb)

2nd: 28 N·m (2.8 kgf·m, 20 ft·lb)

S60C5930

60°

Cylinder body

Loading...

Loading...