1

2

3

4

5

6

7

8

9

10

ENGINE

3-1

ENGINE

ENGINE INSPECTION

MEASURING THE COMPRESSION PRESSURE

The following procedure applies to all of the cylinders.

Measure the compression pressure after checking and

adjusting the valve clearance.

1.

Warm up the engine for several minutes.

2.

Remove:

• Spark plug cap

• Spark plug

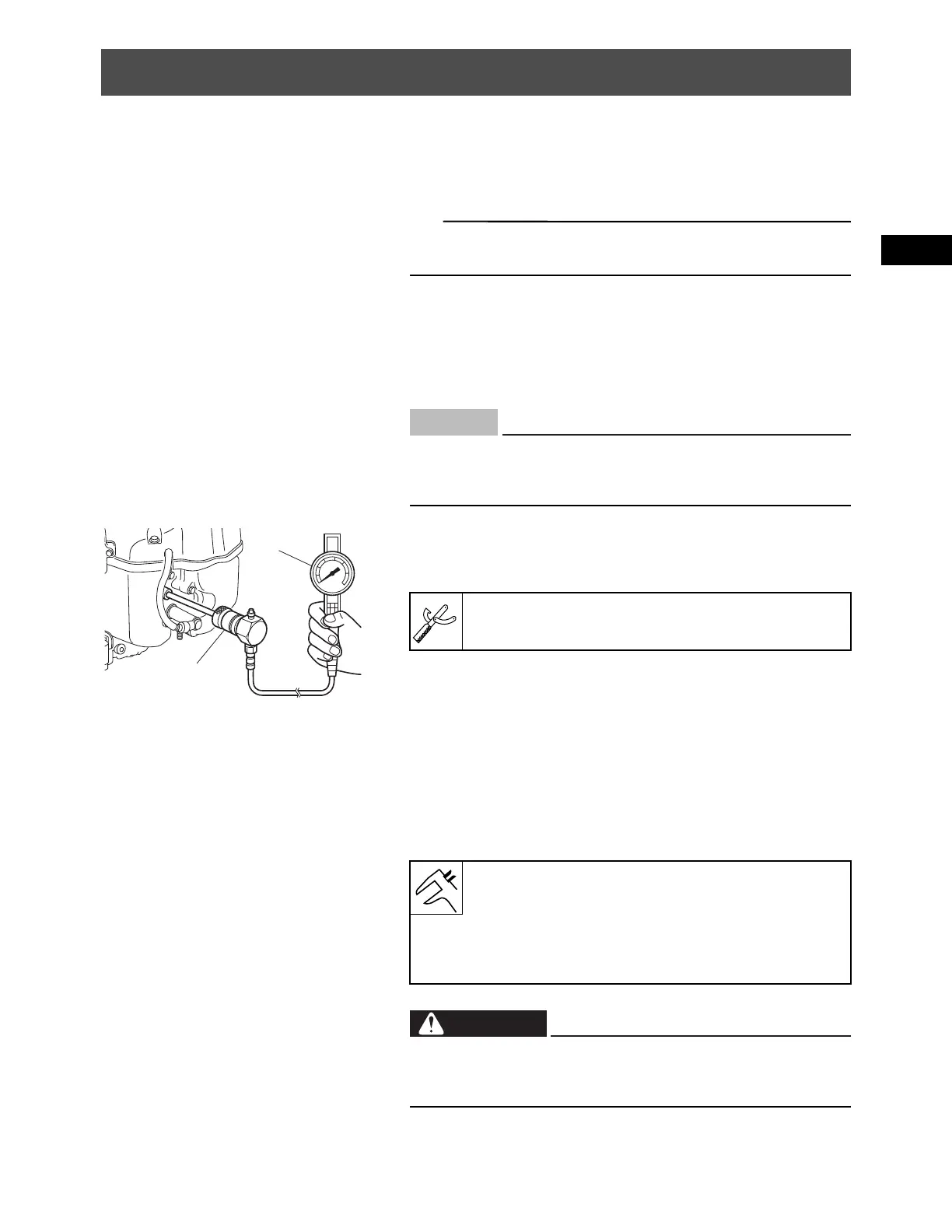

3.

Connect:

• Engine compression tester “1”

• Extension “2”

4.

Measure:

• Compression pressure

Open the throttle and crank the engine until the

needle stop rising on the engine compression tes-

ter.

Out of specification Refer to steps (a) and (b).

Before removing the spark plug, use compressed air

to clean the cylinder head cover to prevent dirt from

falling into the engine.

Engine compression tester:

YU-33223

Standard compression pressure:

1.31–1.45 MPa (13.4–14.8 kg/cm², 190–210

psi)

Limit:

1.03 MPa (10.3 kg/cm², 150 psi)

To prevent sparking the plugs, remove all ignition coil

couplers and fuel injector couplers before cranking

the engine.

Loading...

Loading...