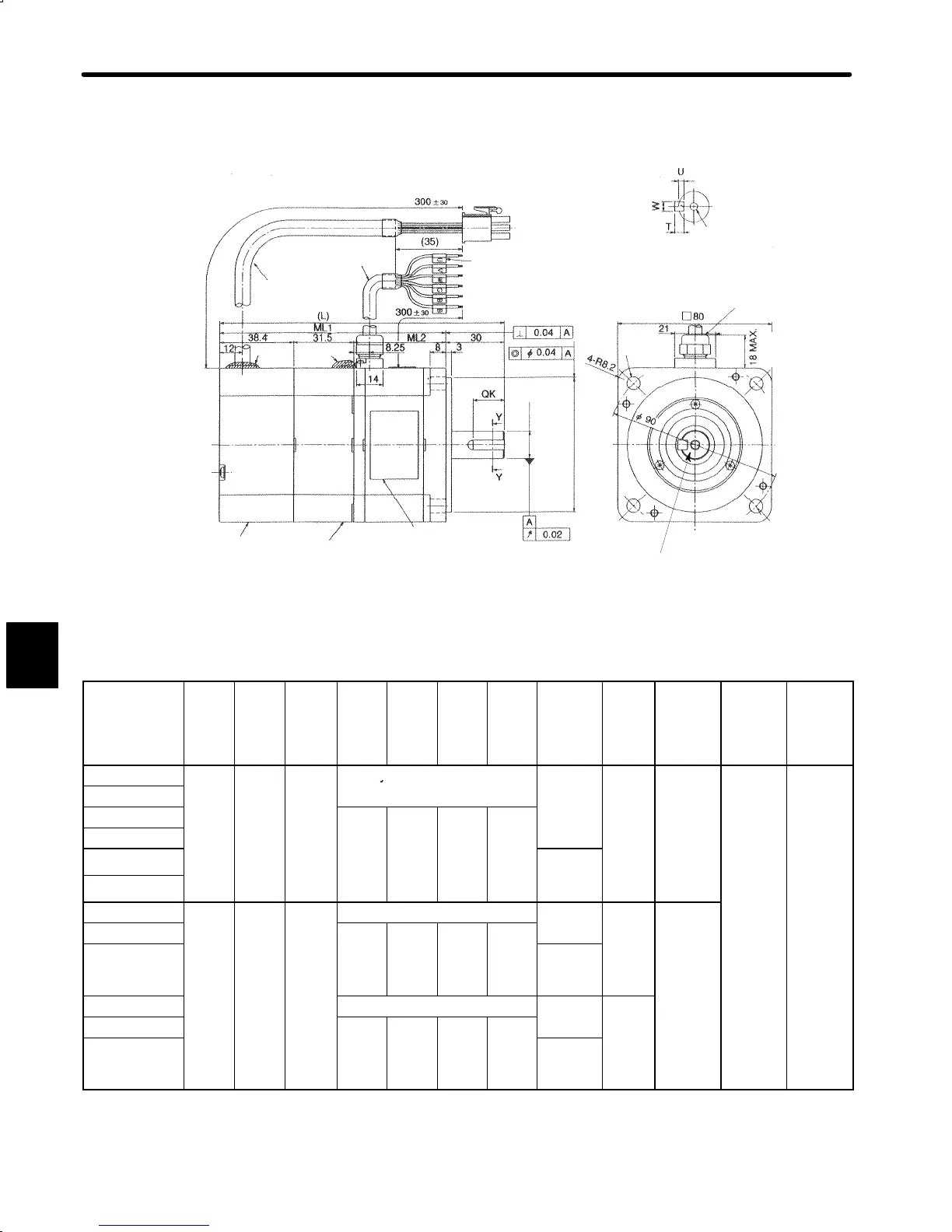

SERVO SELECTION AND DATA SHEETS

5.4.2 Servomotor Dimensional Drawings cont.

326

• 200 W (0.27 HP), 300 W (0.40 HP), 400 W (0.53 HP)

4-φ7(φ0.28)

MTG Holes

Motor Lead

UL2464 φ7

(φ0.29)

Encoder Lead

UL20276φ8

(φ0.31)

12-bit Absolute

Encoder 2048 P/R

Cross-section Y-Y

Marked Wire

(1.18)

Sealant

(0.0016)

(0.0008)

(1.24)

(11.81¦1.18)

(1.38)

(11.81¦1.18)

φ70

-0.030

2.76

-0.0012

0

φ

(

(0.71)

(3.15)

(0.32)

Hex. Nut

14 (0.55)

(φ0.0016)

)

0

(0.12)(0.31)

Screw

Holding Brake

(Deenergisation Operation)

Voltage depends on the last

symbol of motor type:

B: 90VDC C: 24VDC

Brake Holding Torque = Motor

Rated Torque

φ

14

-0.011

0.55

-0.0004

0

φ

(

)

0

(0.55)

(φ3.54)

Nameplate

Shaft end screw

holeSGMP-jjV(W)W16B(C),

with key type only)

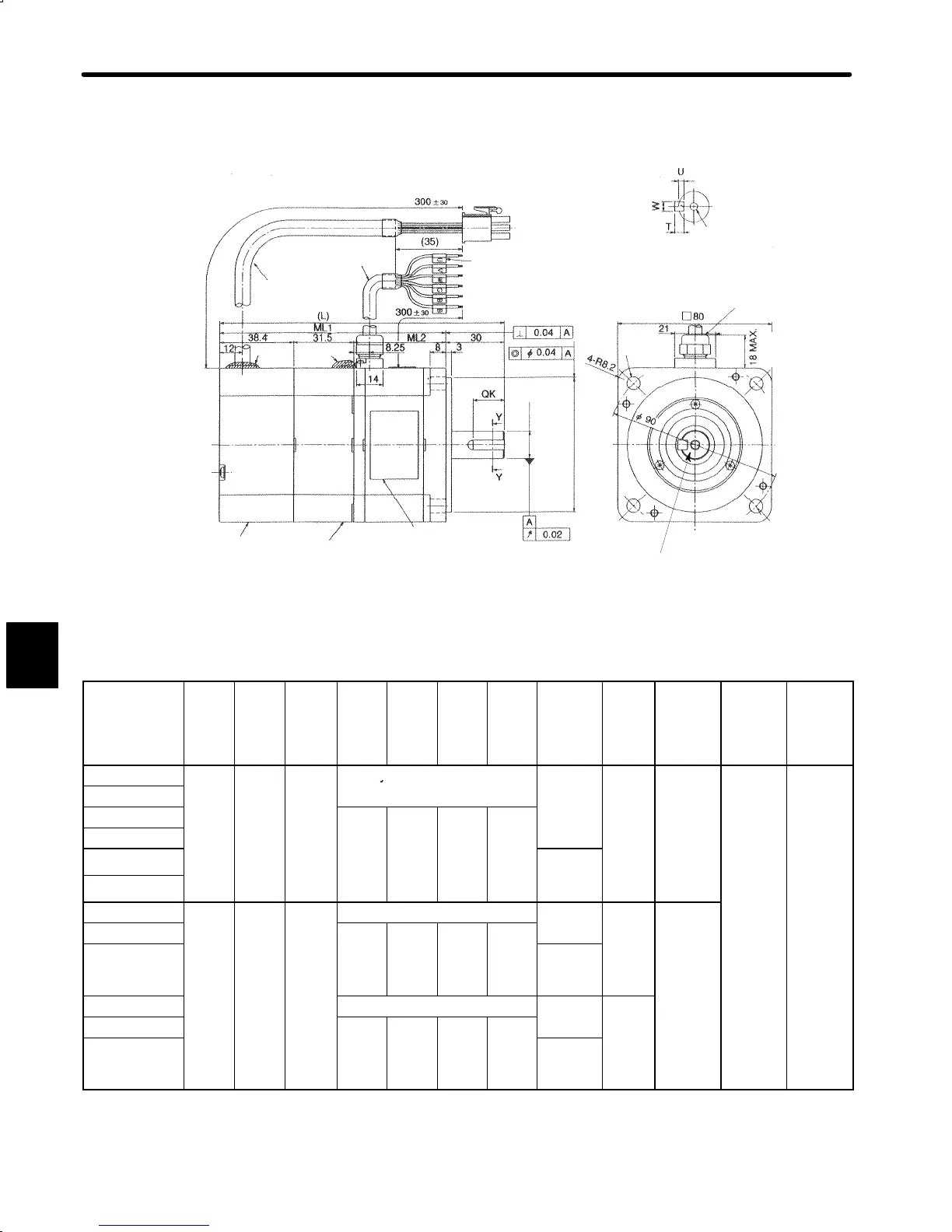

Type SGMP- L LL LM QK U W T Screw

dimen-

sions

Out-

put

W

(HP)

Approx.

mass

kg

(lb)

Allow-

able

radial

load

N (lb)

Allow-

able

thrust

load

N (lb)

02VW12B(C)

148

118

48.1

No key --- 200

2.3

245 68

02WW12B(C)

(5.83) (4.65) (1.89)

(0.27) (5.07)

(55.1) (15.3)

02VW14B(C)

16

3

5

5

02WW14B(C)

(0.63) (0.12) (0.20) (0.20)

02VW16B(C)

M5,

02WW16B(C)

ep

(0.31)

03WW12B(C)

168

138

68.1

No key

--- 300

3.0

03WW14B(C)

(6.61) (5.43) (2.68)

16

3

5

5

(0.40) (6.61)

03WW16B(C)

(0.63) (0.12) (0.20) (0.20)

M5,

depth 8

(0.31)

04VW12B(C) No key

--- 400

04VW14B(C)

16

3

5

5

(0.53)

04VW16B(C)

(0.63) (0.12) (0.20) (0.20)

M5,

depth 8

(0.31)

Note

1) The detector uses a 12-bit absolute encoder 1024 P/R.

5

Loading...

Loading...