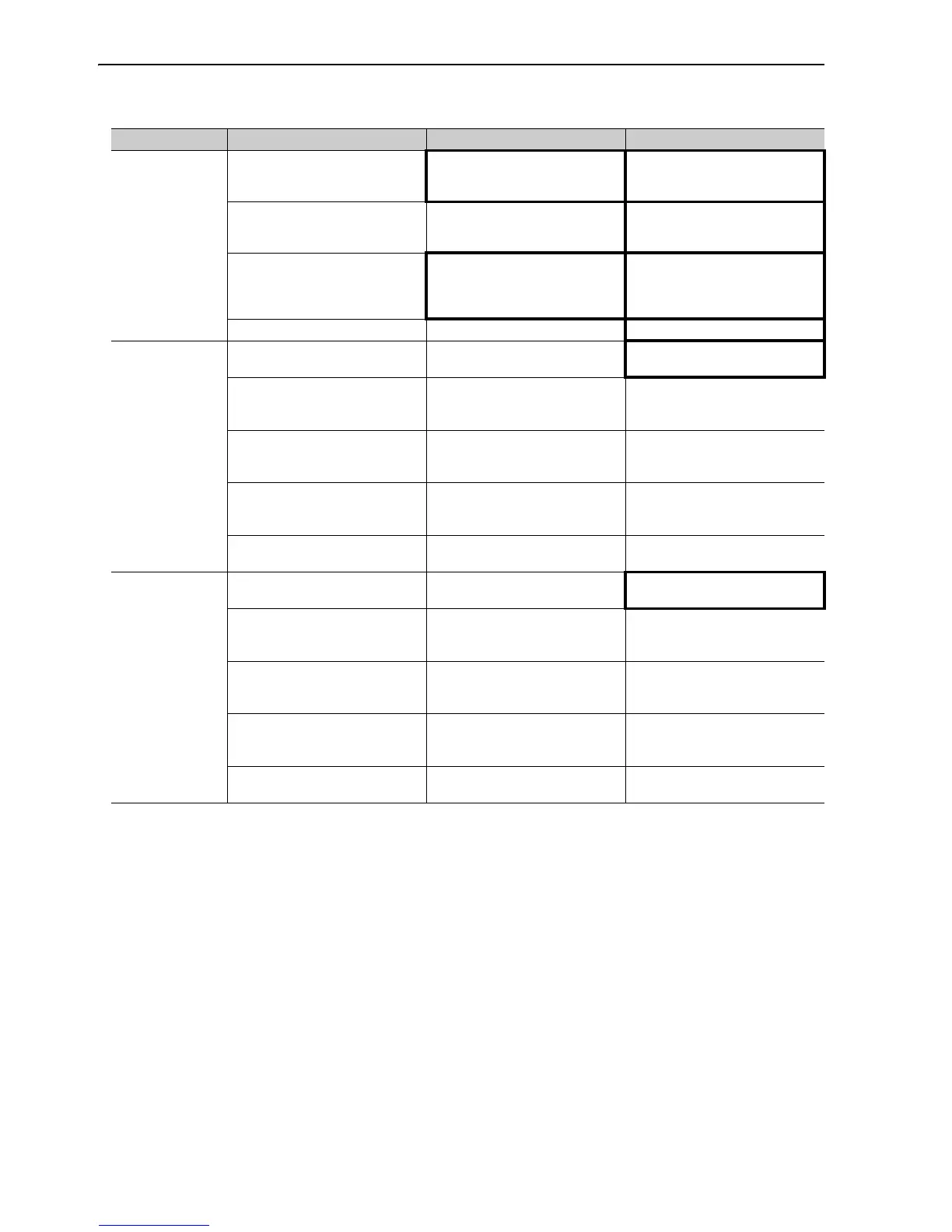

10 Troubleshooting

10-26

Abnormal Noise

from Servomotor

(cont’d)

FG potential varies because of

influence of machines such as weld-

ers at the servomotor.

Check if the machines are correctly

grounded.

Ground machines correctly, and

prevent diversion to the FG at the

PG side.

SERVOPACK pulse counting error

due to noise interference

Check if there is noise interference

on the input/output signal line from

the encoder.

Take measures against noise in the

encoder wiring.

Excessive vibration and shock to

the encoder

Check if vibration from the machine

occurred or servomotor installation

is incorrect (mounting surface accu-

racy, fixing, alignment, etc.).

Reduce vibration from the machine,

or secure the servomotor installa-

tion.

An encoder fault occurred. − Replace the servomotor.

Servomotor

Vibrates at

Frequency of

Approx 200 to 400

Hz

Unbalanced servo gains

Check to see if the servo gains have

been correctly adjusted.

Execute the advanced autotuning.

Speed loop gain value (Pn100) too

high.

Check the speed loop gain value

(Pn100).

Factory setting: Kv = 40.0 Hz

Reduce the speed loop gain

(Pn100).

Position loop gain value (Pn102)

too high.

Check the position loop gain value

(Pn102).

Factory setting: Kp = 40.0/s

Reduce the position loop gain

(Pn102).

Incorrect speed loop integral time

constant (Pn101) setting

Check the speed loop integral time

constant (Pn101).

Factory setting: Ti = 20.0 ms

Correct the speed loop integral time

constant (Pn101) setting.

Incorrect moment of inertia ratio

data (Pn103)

Check the moment of inertia ratio

setting (Pn103).

Correct the moment of inertia ratio

(Pn103) setting.

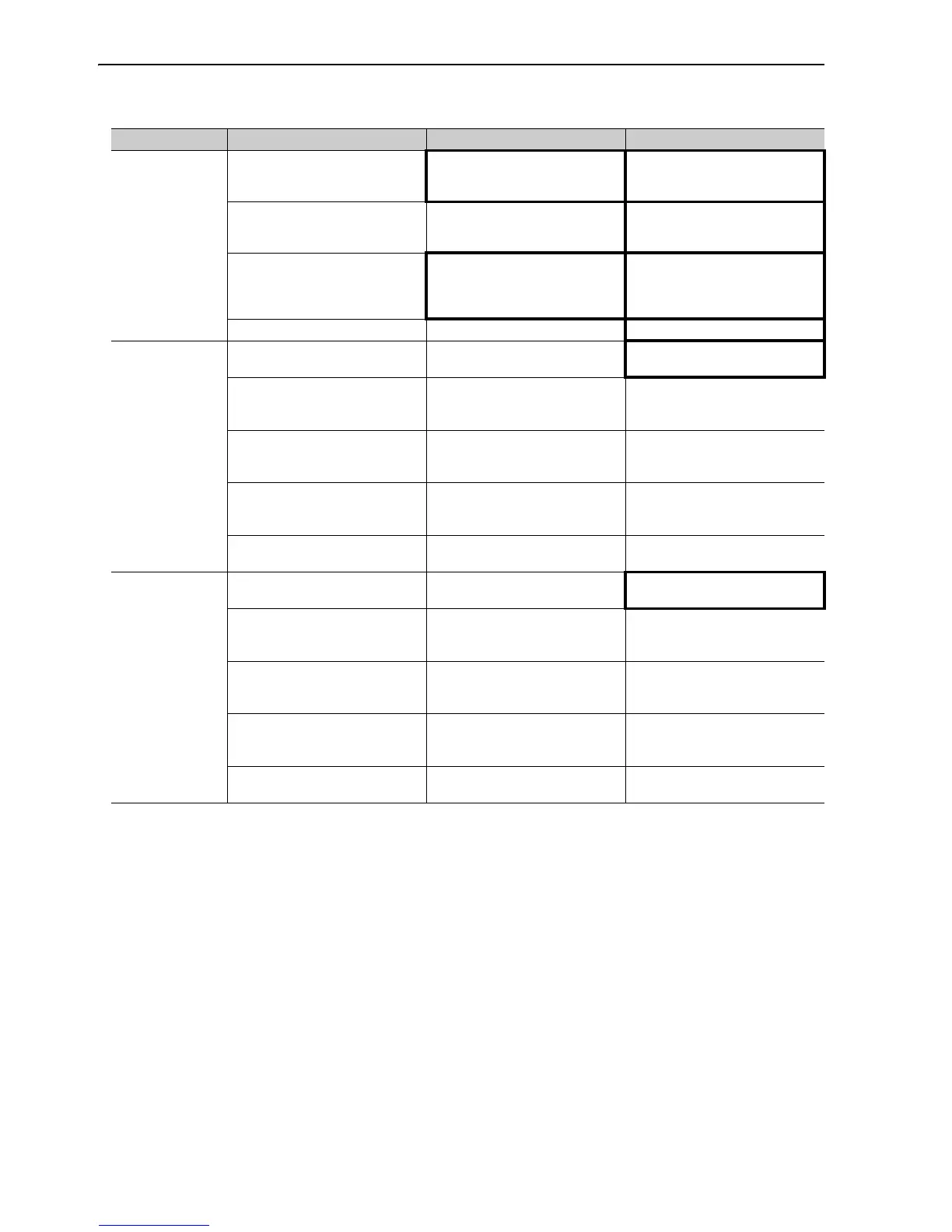

High Rotation

Speed Overshoot

on Starting and

Stopping

Unbalanced servo gains

Check to see if the servo gains have

been correctly adjusted.

Execute the advanced autotuning.

Speed loop gain value (Pn100) too

high

Check the speed loop gain value

(Pn100).

Factory setting: Kv = 40.0 Hz

Reduce the speed loop gain

(Pn100).

Position loop gain value (Pn102)

too high

Check the position loop gain value

(Pn102).

Factory setting: Kp = 40.0/s

Reduce the position loop gain

(Pn102).

Incorrect speed loop integral time

constant (Pn101) setting

Check the speed loop integral time

constant (Pn101).

Factory setting: Ti = 20.0 ms

Correct the speed loop integral time

constant setting (Pn101).

Incorrect moment of inertia ratio

data (Pn103)

Check the moment of inertia ratio

setting (Pn103).

Correct the moment of inertia ratio

setting (Pn103).

Problem Probable Cause Investigative Actions Corrective Actions

Loading...

Loading...