463D SYSTEMS, INC. PN:80-D27 Rev.B

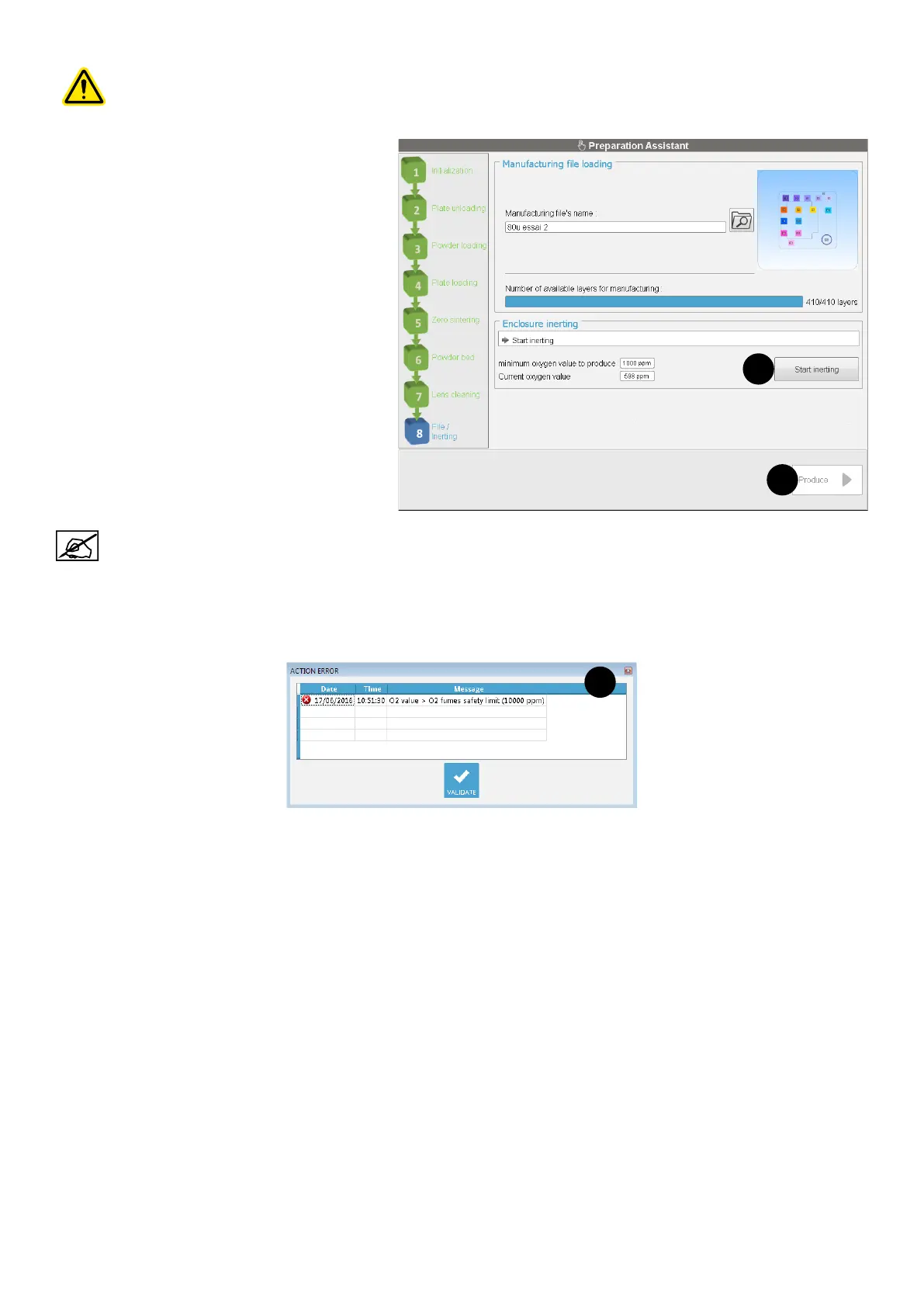

When launching, the inerting process will automatically perform the 2 following phases in this order :

manufacturing chamber inerting at rst, then external lter vessel inerting. Make sure the lter is well

connected to the printer before starting the inerting process.

1. Click on "Start inerting" (1) : Gas and purge

activated – Regulation mode activated – Lens

cleaner turbine OFF and external vessel

valves closed). This step will only inert the

manufacturing chamber.

2. Once the O2 value is lower than the safety

limit, the lens cleaner turbine will activate, and

the vessel valves will open, allowing the fume

vessel inerting.

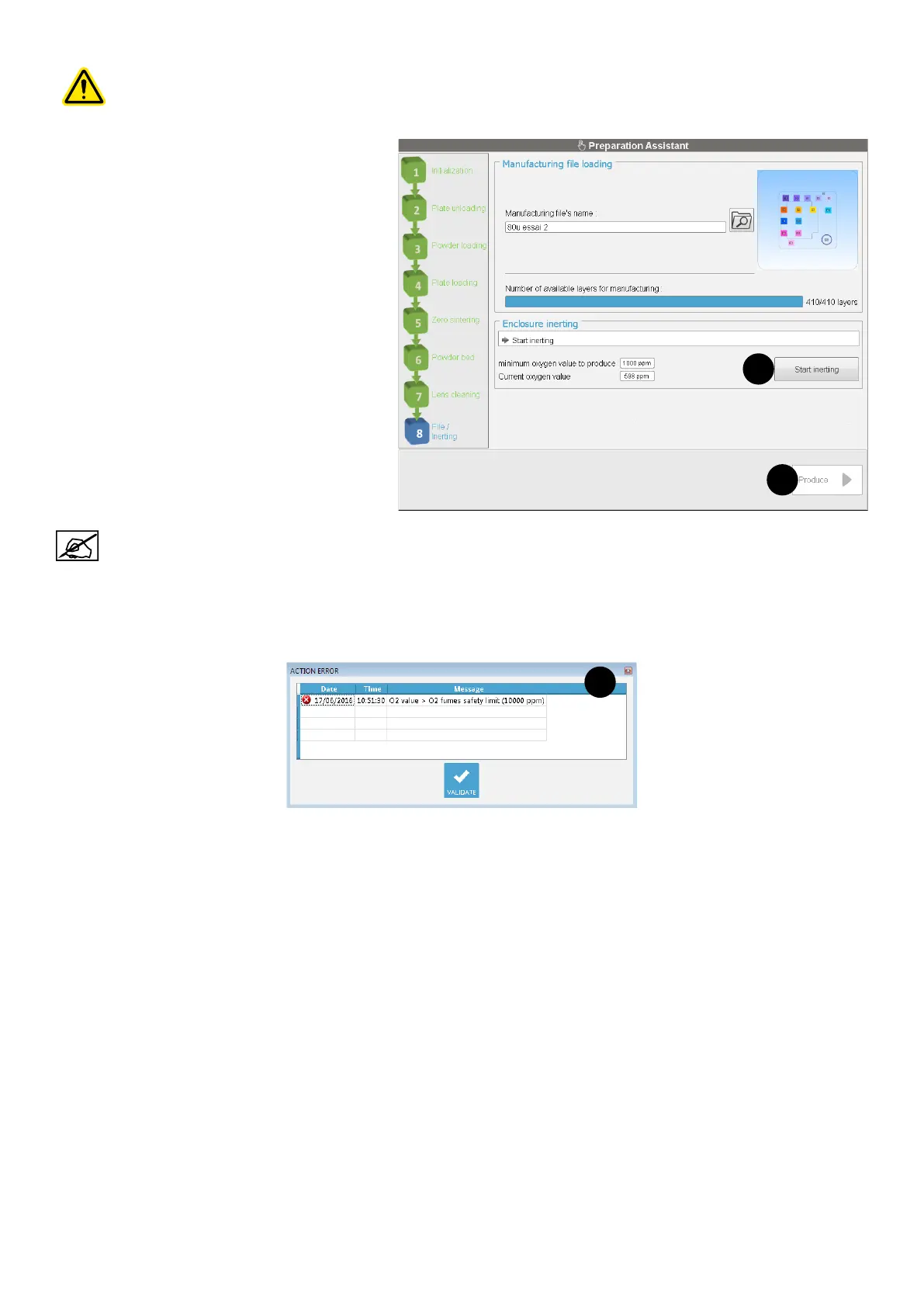

If the O2 level goes higher than the safety limit (during manufacturing or after lter vessel replacement), the lens

cleaner turbine will stop automatically (and the external vessel valves close). It will trigger an oxygen error (3).

3. Once the O2 value is lower than the Minimum Oxygen Value To Produce, then click on "Produce" (2) to go to the

Manufacturing menu.

1

2

3

Loading...

Loading...