713D SYSTEMS, INC. PN:80-D27 Rev.B

Procedure:

WARNING: MULTI-STAGE MAINTENANCE. YOU MUST READ THE ENTIRE PROCEDURE BEFORE BEGINNING.

WARNING : IMPROPER OPERATION OR STORAGE MAY CONTRIBUTE TO CONDITIONS IN THE WORK AREA OR

FACILITY THAT COULD RESULT IN SEVERE PERSONAL INJURY AND PRODUCT OR PROPERTY DAMAGE. CHECK

THAT EQUIPMENT IS PROPERLY INSTALLED AND USED AS INTENDED.

1. Check that the 2 pneumatic lter valves are closed:

• Access Step #7 of the Preparation Assistant,

• The graphic display of the closed lter valves is

. If valves are not closed (corresponding graphic ), click on “Can-

ister valves” button on the control panel to close them:

Step 2 is performed to disconnect lter from machine. When changing the lter, leave the pneumatic

valves on the tubes. Only open the clamps on the lter vessel (as indicated below), and remove the valves

from the vessel.

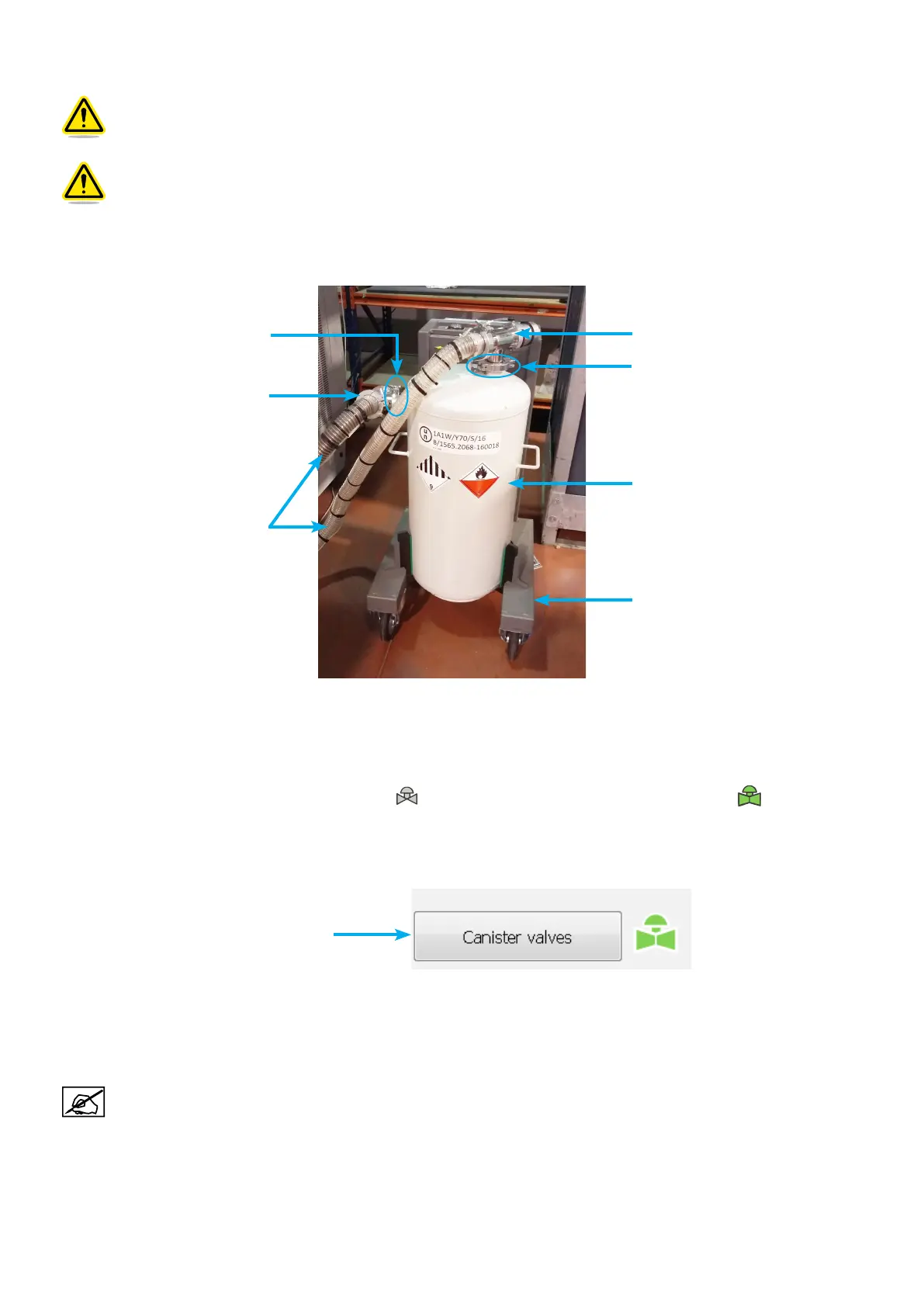

Inlet pneumatic valve

Filter inlet port (side connection)

(Dirty in)

Tubes connected

to the printer

Outlet pneumatic valve

Filter outlet port (top connection)

(Clean out)

Filter vessel

Transportation cart

Button to close

the lter valves

Loading...

Loading...