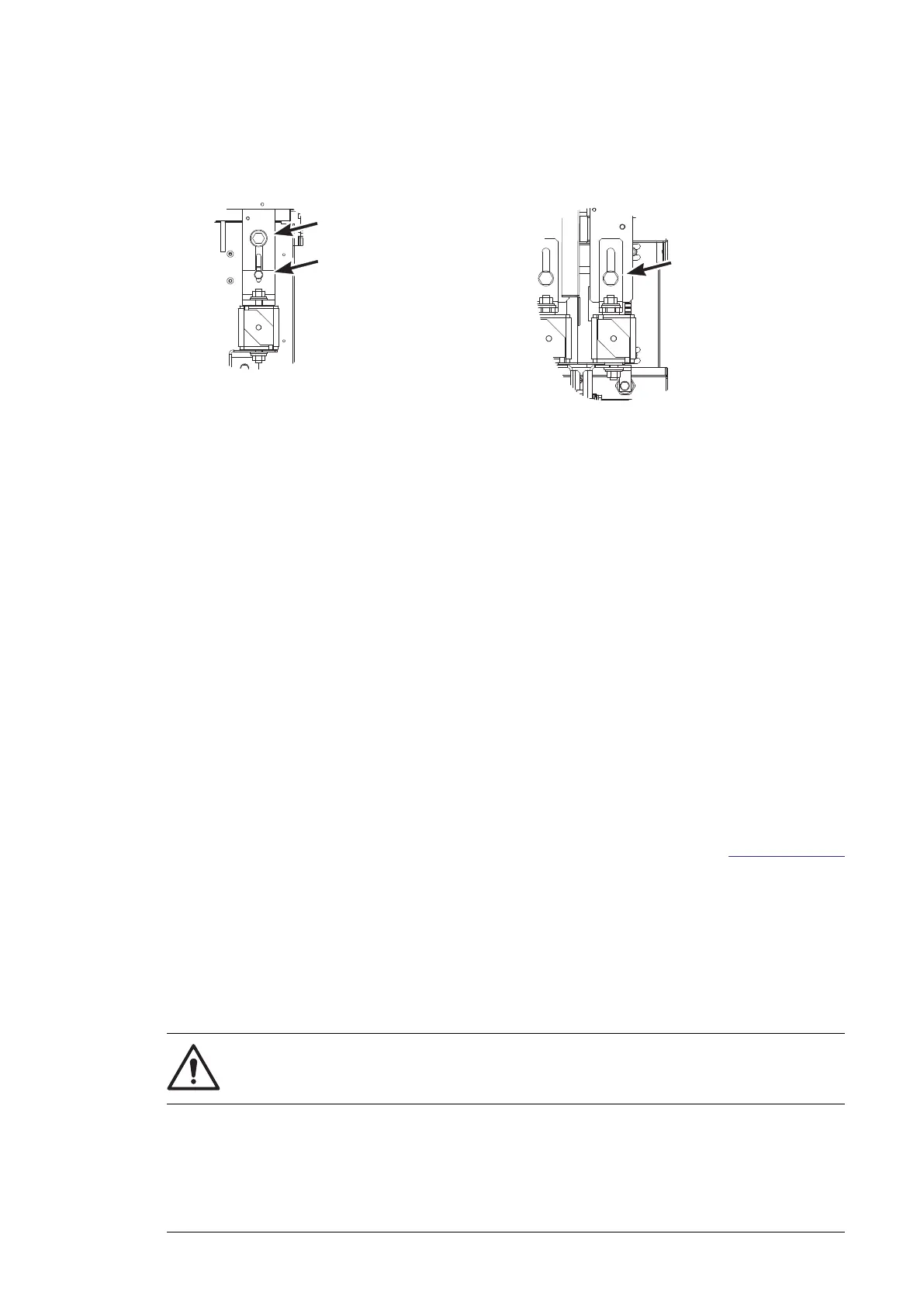

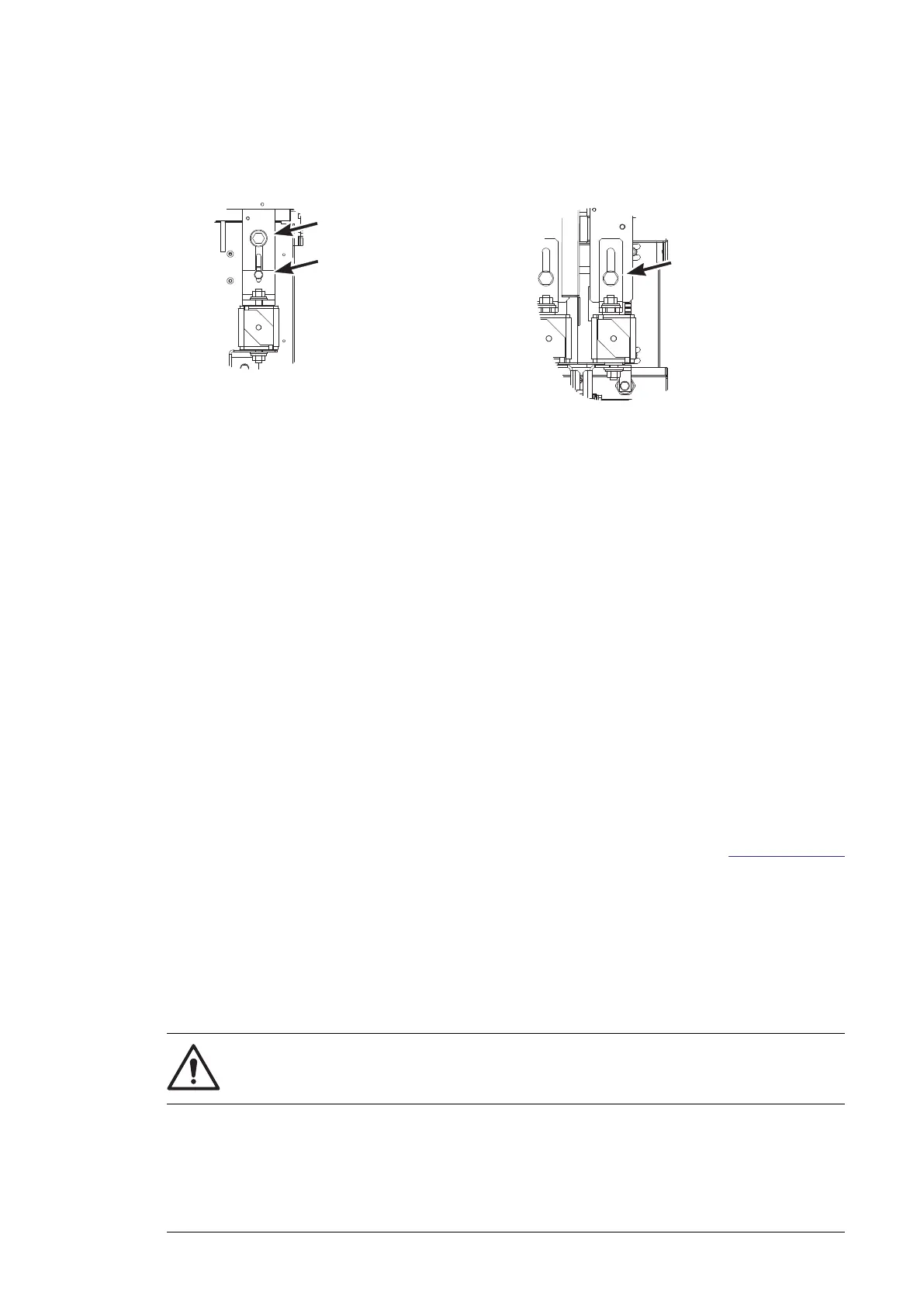

8. Tighten the mounting screws of the top busbars to torque as shown.

With DC switch (+F286)

Without DC switch

70 N·m (52 lbf·ft)

9 N·m (6.6 lbf·ft)

9. Tighten the fuse block nuts to torque as follows:

• Cooper-Bussmann fuses: 50 N·m (37 lbf·ft)

• Mersen (Ferraz Shawmut) fuses: 46 N·m (34 lbf·ft)

• Other: Refer to the fuse manufacturer’s instructions.

10. Reinstall the shroud removed earlier. Tighten the screws to 6 N·m (4.4 lbf·ft).

Capacitors

The DC link of the drive contains several electrolytic capacitors. Operating time, load, and

surrounding air temperature have an effect on the life of the capacitors. Capacitor life can

be extended by decreasing the surrounding air temperature.

Capacitor failure is usually followed by damage to the unit and an input cable fuse failure,

or a fault trip. If you think that any capacitors in the drive have failed, contact ABB.

■ Reforming the capacitors

The capacitors must be reformed if the drive has not been powered (either in storage or

unused) for a year or more. The manufacturing date is on the type designation label. For

information on reforming the capacitors, see Capacitor reforming instructions (3BFE64059629

[English]).

Control units

■ Replacing the memory unit

After replacing a control unit, you can keep the existing parameter settings by transferring

the memory unit from the defective control unit to the new control unit.

WARNING!

Do not remove or insert the memory unit when the control unit is powered.

1.

Stop the drive and do the steps in section Electrical safety precautions (page 57) before

you start the work.

2. Make sure that the control unit is not powered.

Maintenance 127

Loading...

Loading...