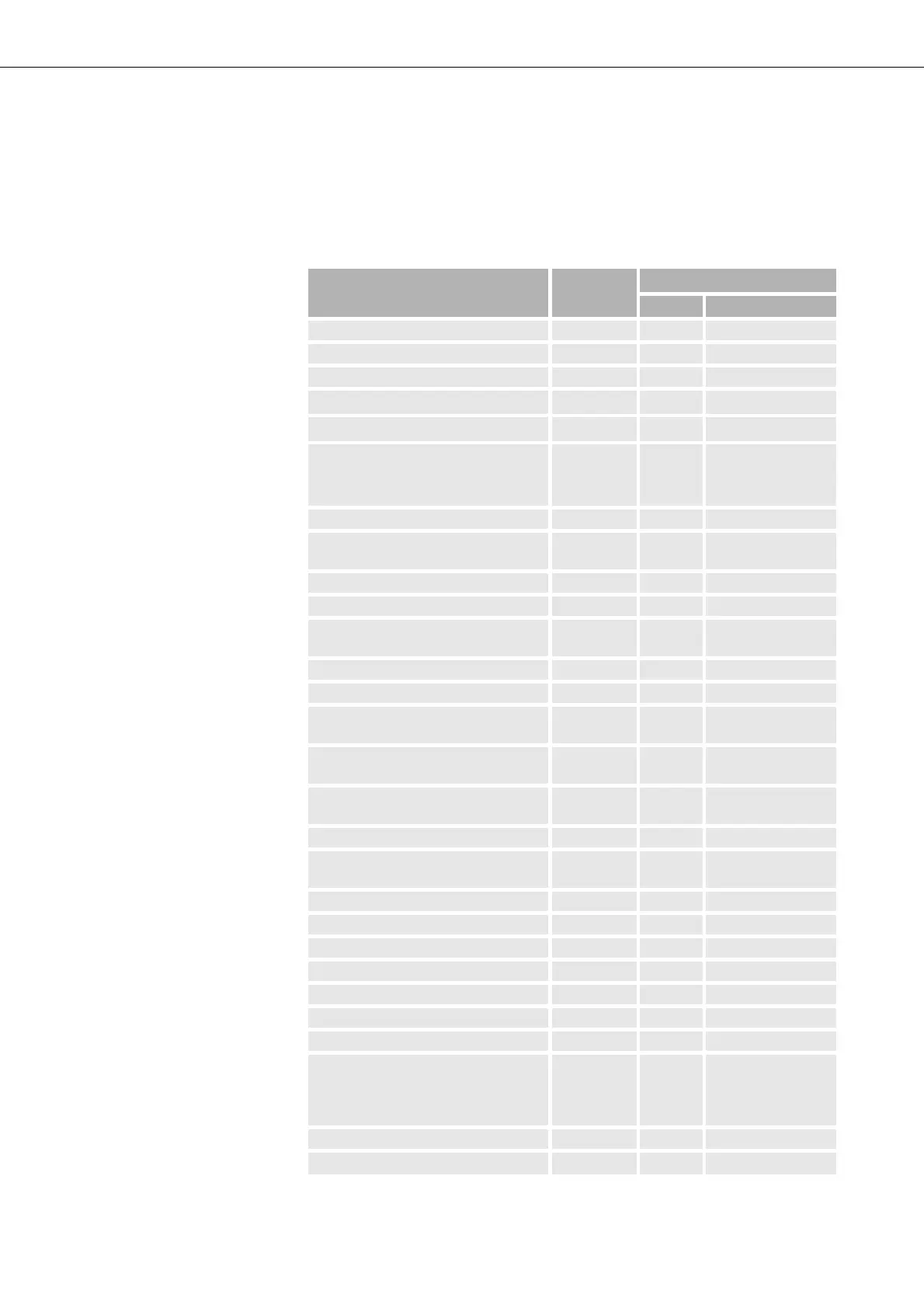

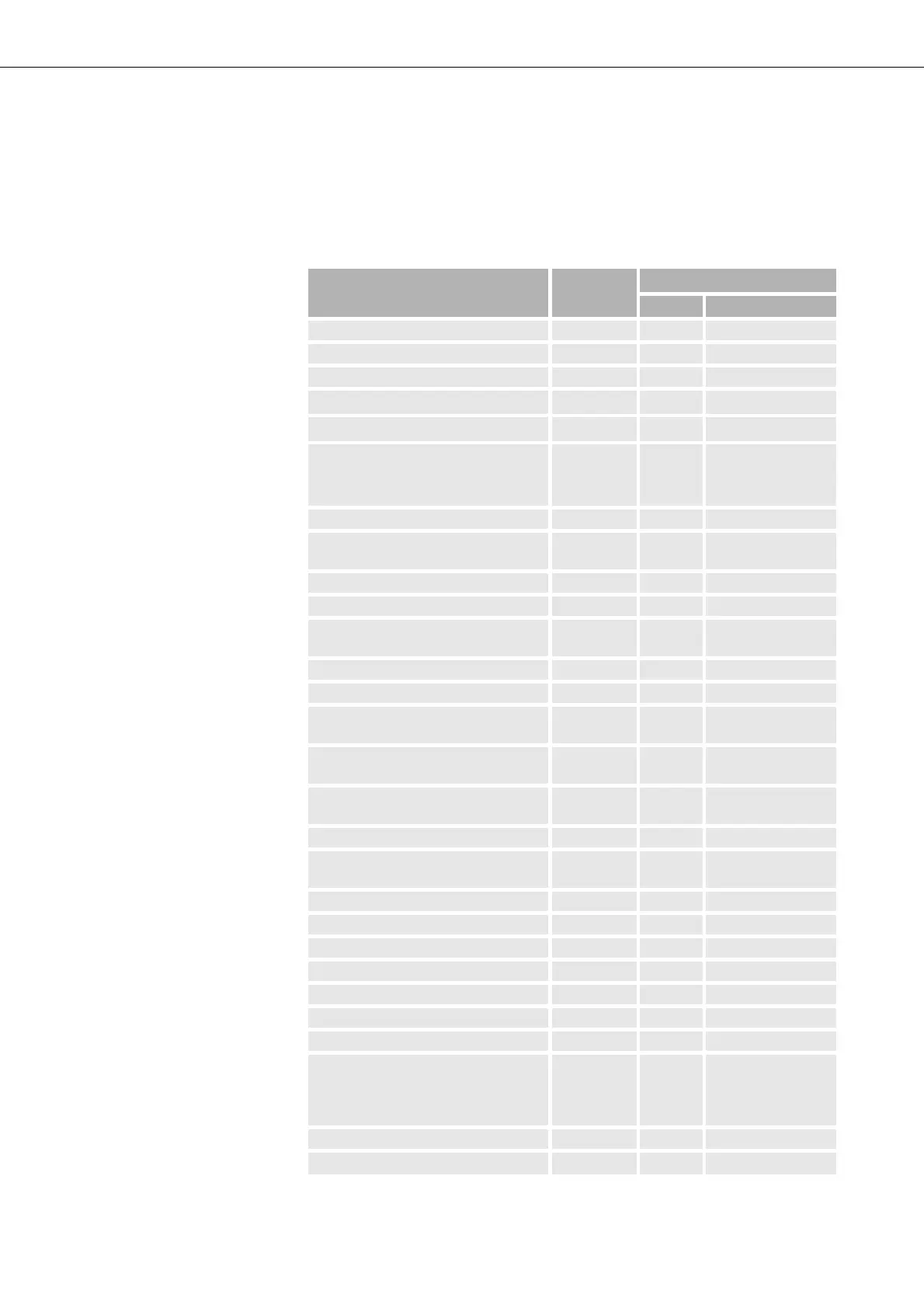

CHECKLISTS

88 FOX615Installation

4.5 Installation material

Table 14: Checklist for material

Description Identifica-

tion

Quantity

Units Remark

Screws, washers, crimp lug subrack

- Screws flat head (slot or Phillips) M6 4 per subrack

- Screws flat head (slot or Phillips) M6 4 per cable tray

- Washer for 6 mm screws

a

a. Only required if the subrack earthing is done via an earthing cable.

1 per bonding point

- Toothed washer for 6 mm screws

a

1 per bonding point

- Crimp lug for 6 mm screws for the

subrack earthing cable

a

(10 mm

2

cross section)

1 per bonding point

Screws FAMO1, FAMO1-F and heat

deflection

- Screws flat head (slot or Phillips) M6 4 per FAMO1

- Screws flat head (slot or Phillips) M6 4 per FAMO-F

- Screws flat head (slot or Phillips) M6 4 per heat deflection

shield R7AI

Screws ETSI adapters:

- Screws flat head (slot or Phillips) M6 4 per pair of ETSI

adapters 2 HE

- Screws flat head (slot or Phillips) M6 8 per pair of ETSI

adapters 9 HE

- Screws flat head (slot or Phillips) M6 10 per pair of ETSI

adapters 11 HE

Captive nuts (19-inch rack): normally part of the

rack

- Subrack and cable tray 8

-FAMO1 4

-FAMO1-F 4

- Heat deflection shield R7AI 4

Cable ties 2 per signal cable

Latching clips for connectors

- provided with signal cables

- ordered separately for connector

(sets)

2 per standard con-

nector

Labels for cables as required

Loading...

Loading...