AESFill AF1C Machine Manual 45/58 Cleaning & Accessories

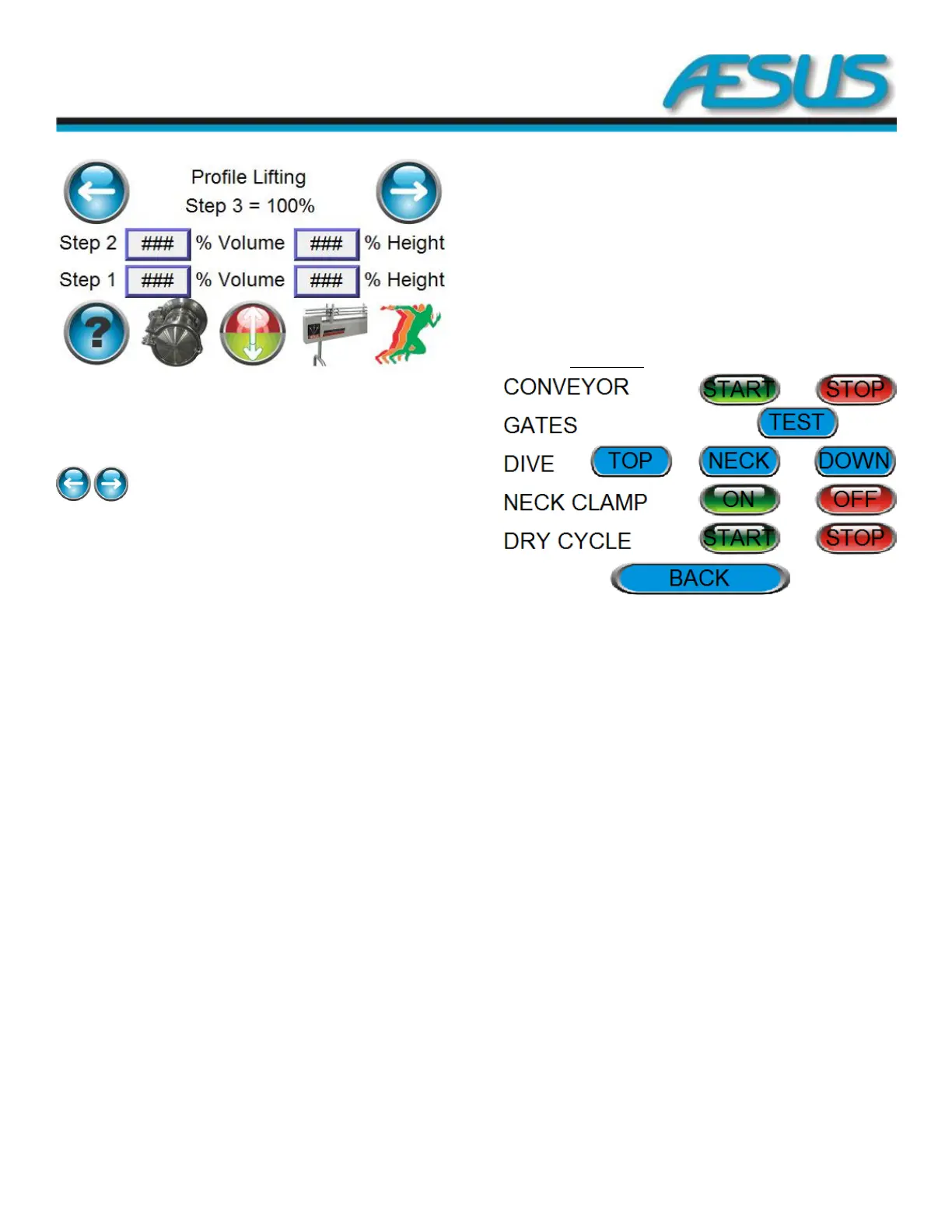

Figure 8-18: Profile Lifting Setup Screen

Step 3: Is always 100% of volume at 100% neck height.

Step 2: Settings are always equal to or greater than step 1.

Step 1: It will only start once the bottom delay is over.

: Allow to go back to the previous page or go to

the next.

Bottom Banner: Change menu

Example:

Step 3 100% volume at 100% heights

Step 2 90% volume at 25% heights

Step 1 40% volume at 45% heights

The sequence of events will be:

1. Container(s) presence confirmed.

2. Nozzle(s) go down.

3. Start filling.

4. The bottom delay will take place followed by the

steps.

5. Step 1 40% of the remaining volume will be

dispensed during the travelling to the first position

at 25% of the neck height.

6. At the end of step 2, 90% of the volume will have

been dispensed and the nozzles will be at 45% of the

total travelling distance.

The remaining 10% of the volume will be dispensed during

the travelling of the nozzle of the last 55% of the container

neck height (long thin neck).

8.1.9 Test Screen

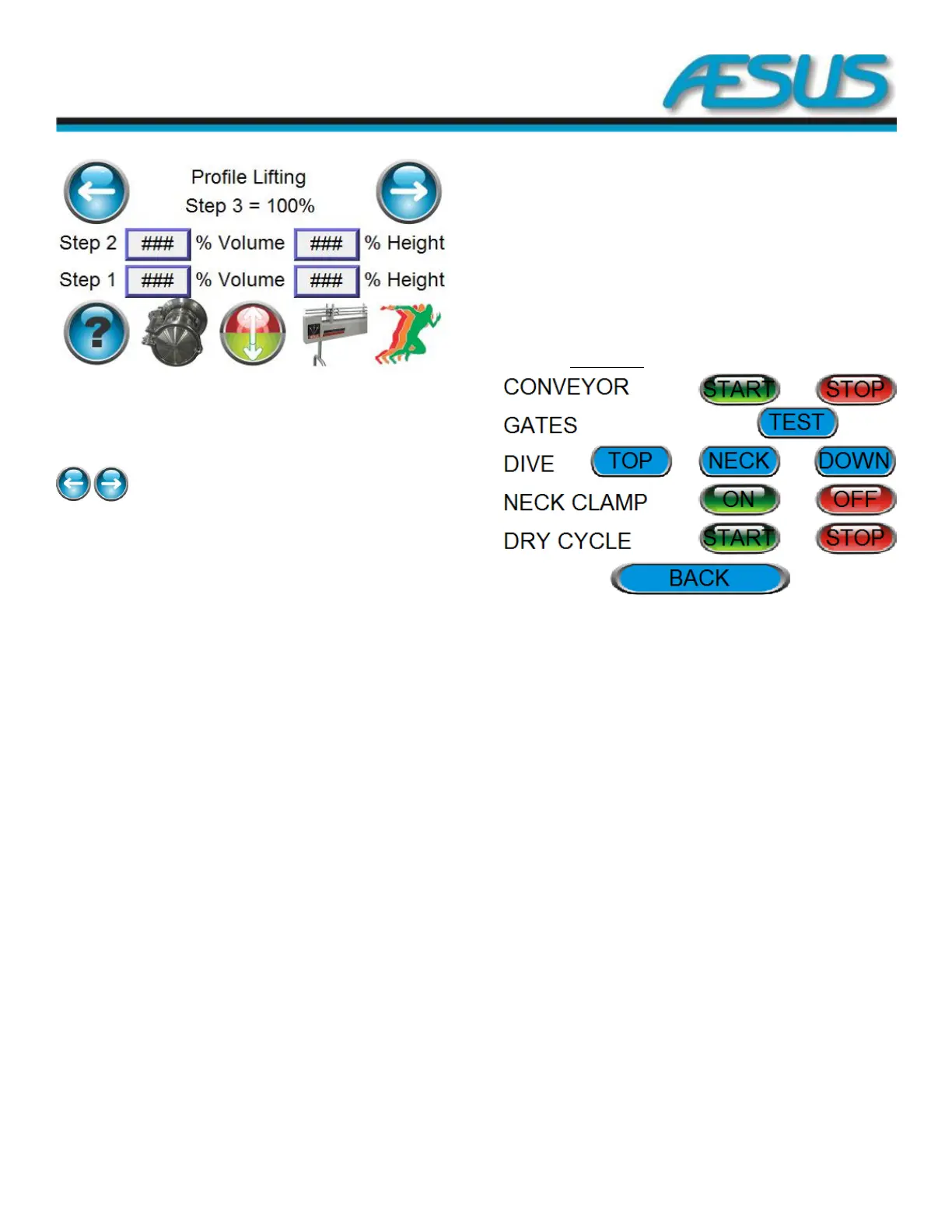

Figure 8-19: Test Screen

Conveyor START/STOP: Start or stop the testing of the

conveyor alone.

Gates TEST: Test the gates.

Dive TOP: Send the nozzle to the top position to test it.

Dive NECK: Send the nozzle to the Neck position to test it.

Dive DOWN: Send the nozzle to the down position to test it.

Neck clamp ON/OFF: Clamp or UN-clamps the clamps to test

them.

Dry Cycle START/STOP: Start or stop a dry run of the filling

sequence.

Back: Go back to the main menu

Loading...

Loading...