Publication 1766-RM001A-EN-P - October 2008

220 Math Instructions

ACS - Arc Cosine

Instruction Type: output

Use the ACS instruction to take the arc cosine of a number (source in

radians) and store the result (in radians) in the destination. The source

must be greater than or equal to -1 and less than or equal to 1. The

resulting value in the destination is always greater than or equal to 0 and

less than or equal to π, where π = 3.141592.

Enter the following parameters when programming this instruction:

• Source is the address to compute the arc cosine.

• Destination is the address to store the arc cosine of the Source.

Address Levels for the operands involved in the ACS can be ALL word,

ALL double word, ALL float, or a combination. These operands shall

undergo a conversion to float. The calculation of the source (in float) is

then performed, and the result is then cast to the data type of Destination.

ABS

Arc Cosine

Source N7:0

0<

Dest N7:1

0<

ACS

Execution Time for the ACS Instruction

Controller Data Size When Rung Is:

True False

MicroLogix 1400 word 18.0150 µs 0.3750 µs

long word 18.3070 µs 0.4150 µs

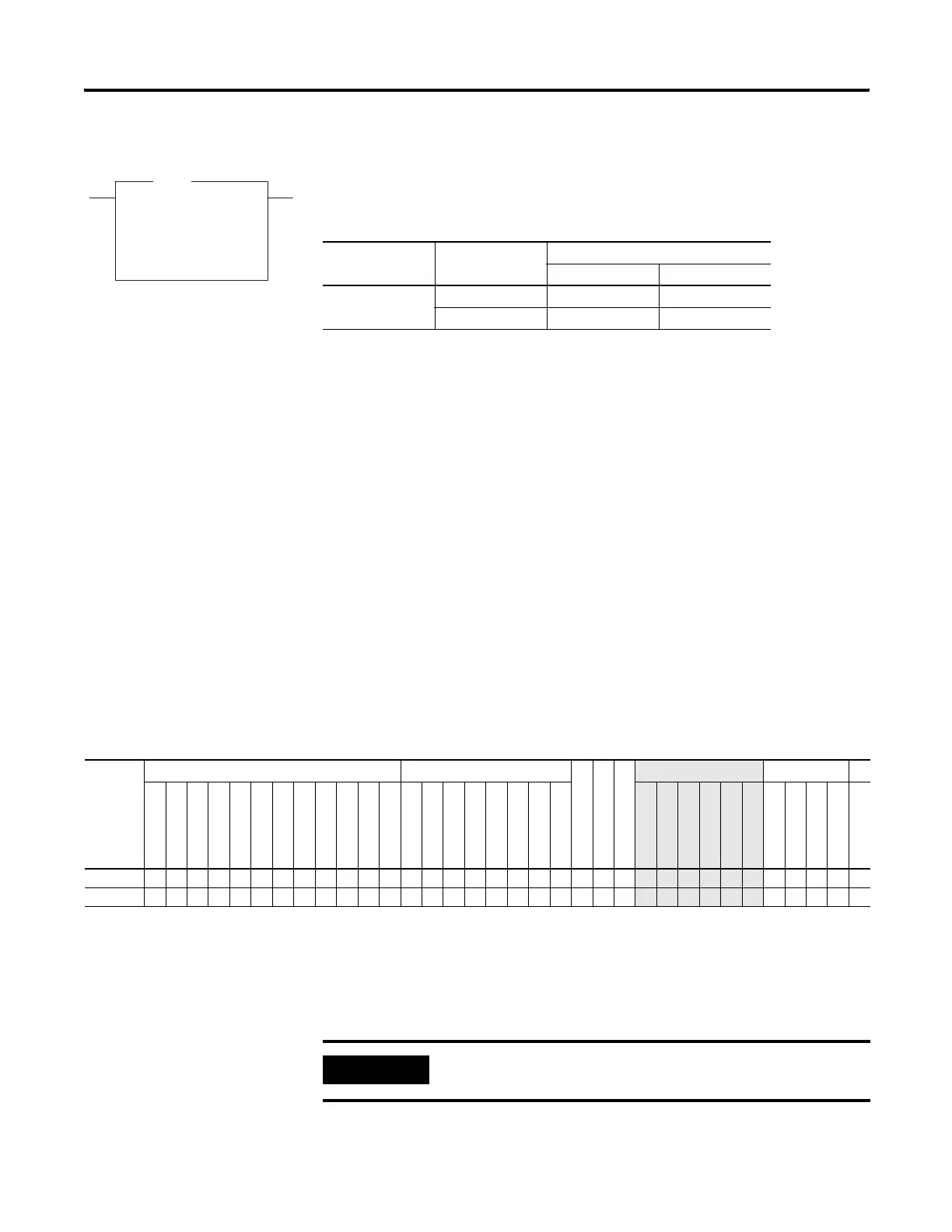

ACS Instruction Valid Addressing Modes and File Types

For definitions of the terms used in this table see Using the Instruction Descriptions on page 92.

Parameter

Data Files

Function Files

(1)

CS - Comms

IOS - I/O

DLS - Data Log

(2)

Address Mode

(3)

Address Level

O

I

S

B

T, C, R

N

F

ST

L

MG, PD

RI/RIX

PLS

RTC

HSC

PTOX, PWMX

STI

EII

BHI

MMI

LCD

Direct

Indirect

Immediate

Int16

Immediate Int32

Immediate Float

Bit

Word

Double Word

Element

Float

Source •• •••• • • • • • • • ••••

Destination • • • • • • • •

• • •• •

(1) PTOX and PWMX files are only for use with MicroLogix 1400 BXB or BXBA unit.

(2) The Data Log Status file can only be used for the following math instructions: ADD, SUB, MUL, DIV, NEG, and SCP.

(3) See Important note about indirect addressing.

IMPORTANT

You cannot use indirect addressing with: S, MG, PD, RTC, HSC, PTOX,

PWMX, STI, EII, BHI, MMI, CS, IOS, and DLS files.

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Loading...

Loading...