533 Publication 1766-RM001A-EN-P - October 2008

Chapter

25

LCD - LCD Information

This chapter describes how to use the LCD functions.

LCD Overview

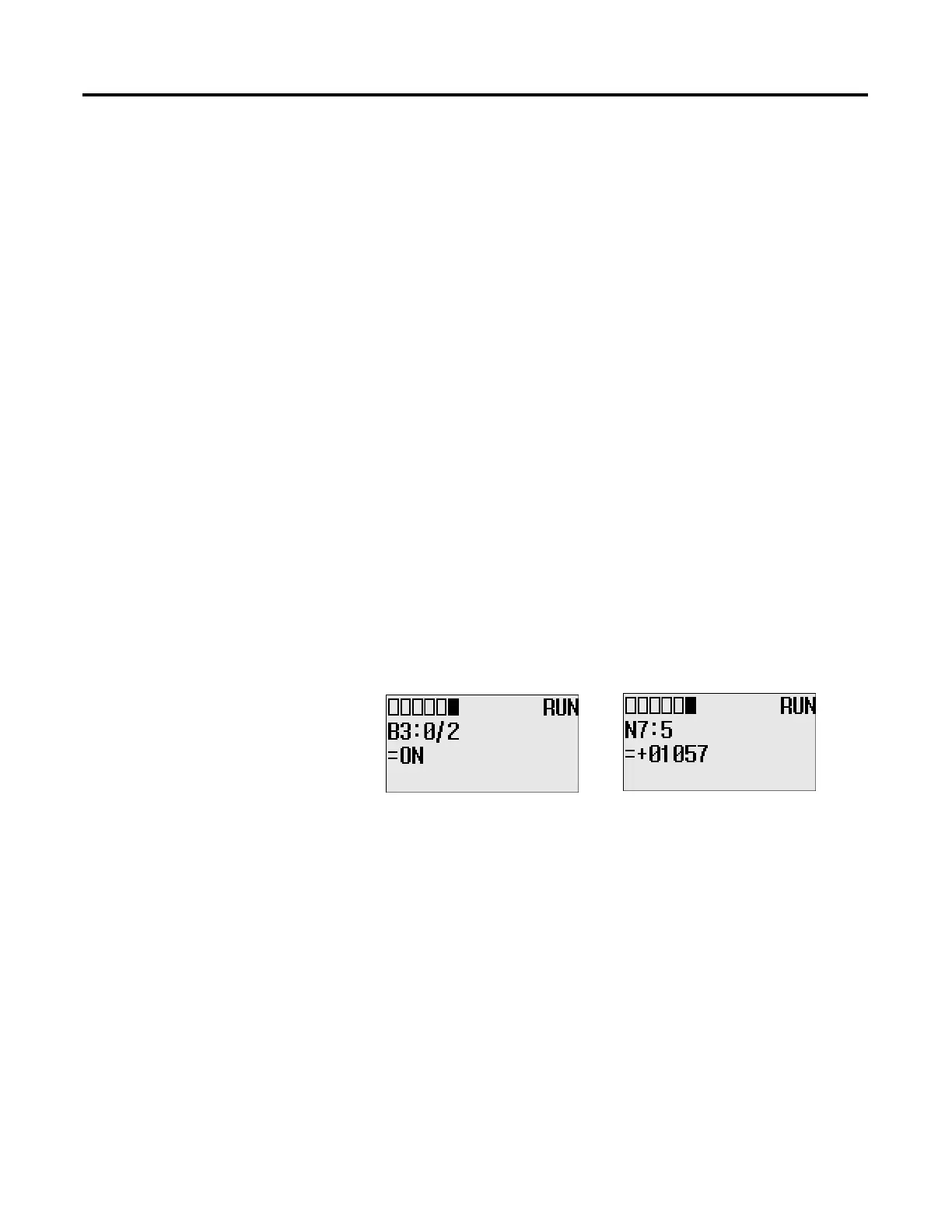

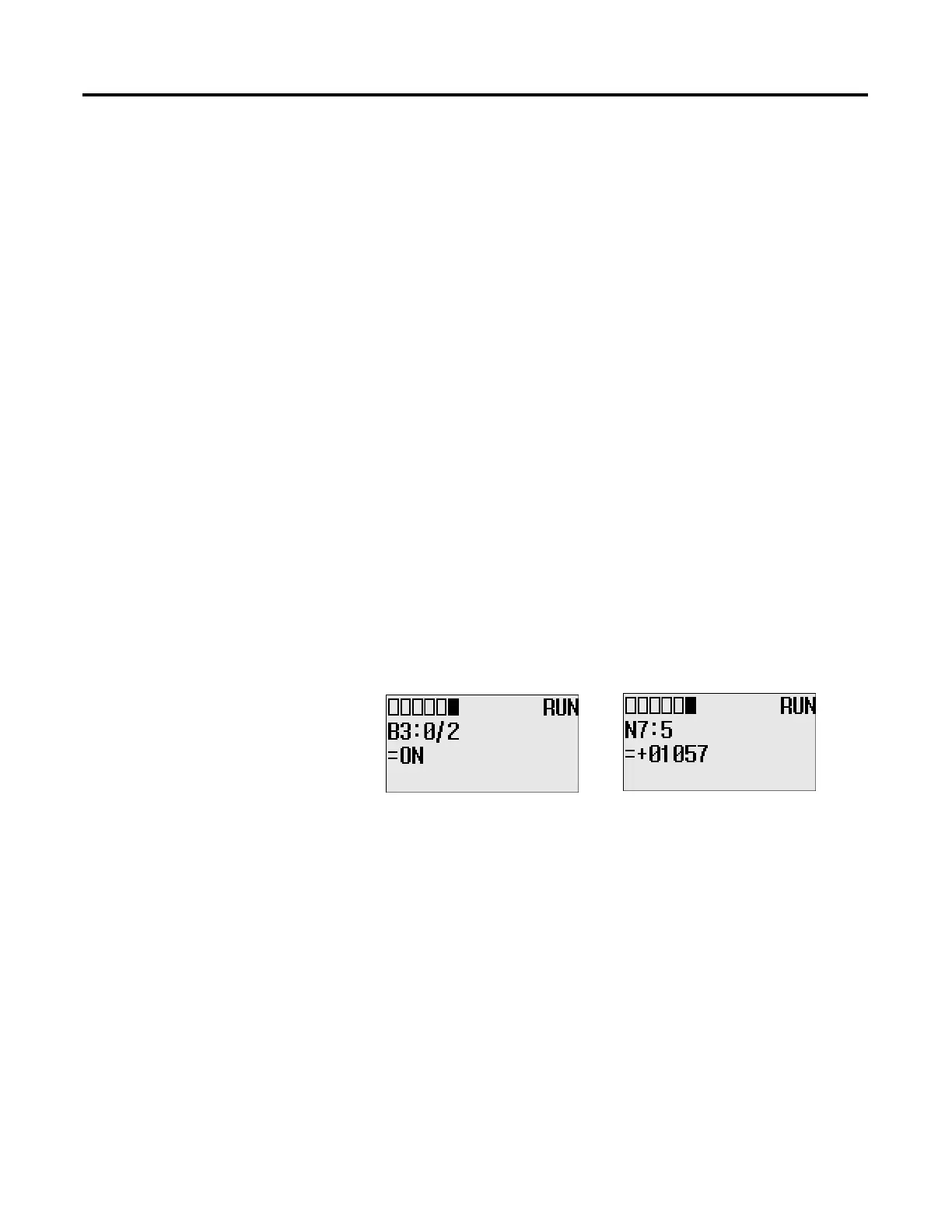

Through the embedded LCD, your MicroLogix 1400 lets you monitor bit,

integer and long integer data within the controller, and optionally modify

that data, to interact with your control program. Similarly to the optional

1764-DAT for the MicroLogix 1500 controllers, the embedded MicroLogix

1400 LCD allows users access to 256 bits, 256 integers and 256 long

integers, each of which can be individually protected. If you need to

know the speed of a conveyor, the status of a remote sensor, or how close

your process is running relative to its optimal temperature, you can just

monitor your LCD.

You can manually start an operation, change a timing sequence, or make

adjustments to a counter, and use the LCD to simulate pushbuttons or

numeric entry devices. By simply moving or copying data in and out of

the bit and integer files, you now can monitor and modify the parameters

that your controller uses.

Making use of the new MicroLogix 1400 “LCD Instruction”, your controller

can directly interface with a local operator using your ladder logic. The

LCD Instruction executes under two modes of operation, the first mode

being ladder logic output to the display only (hereafter called “Display

Only mode”). In this Display Only mode, up to three lines of data, with

up to 16 characters per line, can be sent to the display from the ladder

logic running in the controller. Think of this as messaging to the LCD.

These lines can consist of combinations of Bits, Integers, Long Integers,

Floating and String characters. So now the control program can send alert/

alarm messages, I/O data values, simple text messages, or combinations

of these messages to the operator. These messages can be triggered by

events (input sensors, timer “done bits”, message from another controller,

etc.), or based on a scheduled action (using the embedded real time

clock, or free running timers).

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Loading...

Loading...