Cleaning, maintenance and repairs

BAG0175.3 07.18

12.6 Check the coupling device

DANGER!

Replace a damaged drawbar with a new one immediately -

for road traffic safety reasons.

Repairs may only be carried out by the manufacturer

factory.

For safety reasons, it is forbidden to weld on and drill holes

in the drawbar.

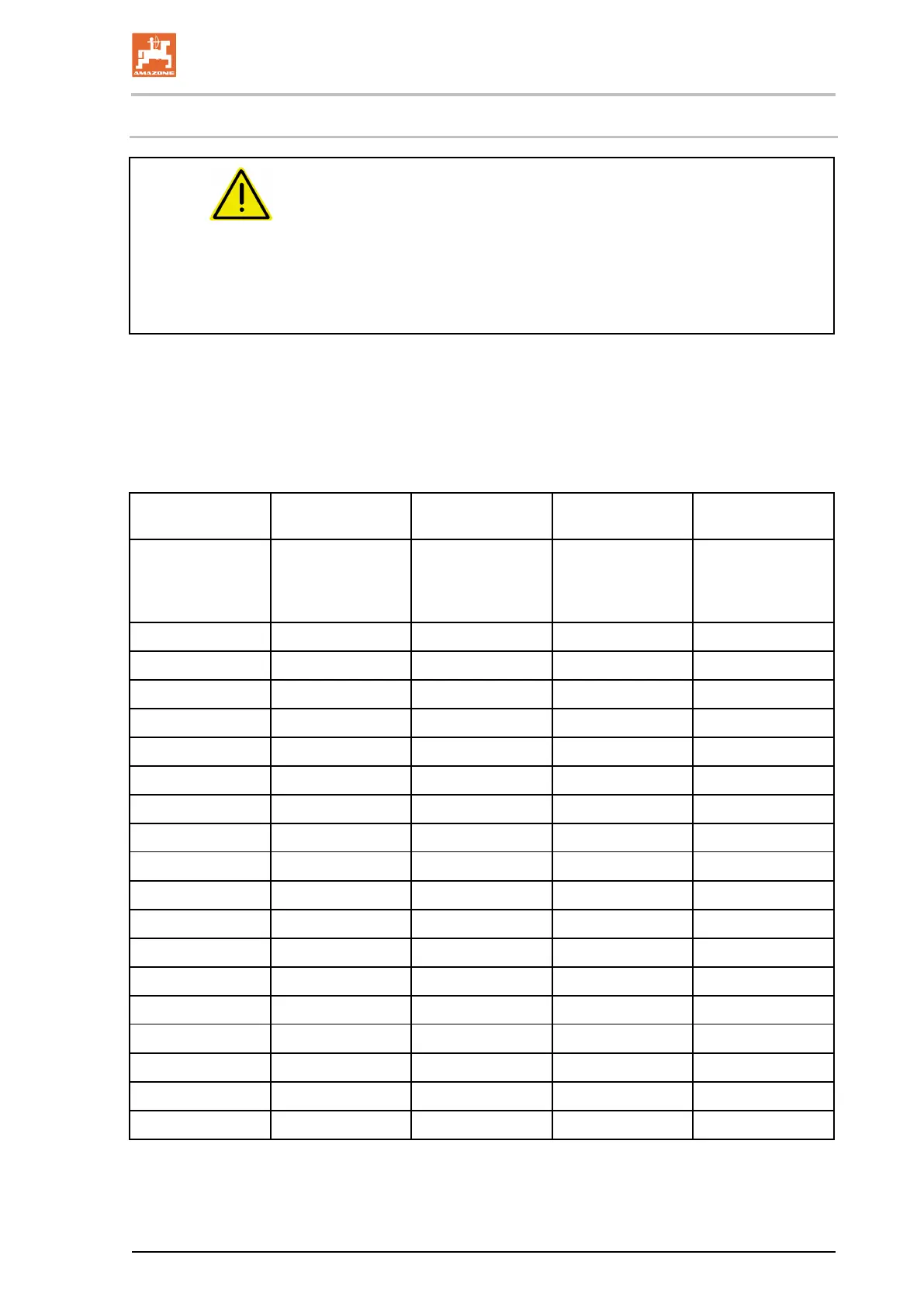

Check the coupling device (drawbar, lower link traverse, ball coupling,

drawbar eye) for the following:

• damage, deformation, cracks

• wear

• tight fit of the fastening bolts

Coupling device Wear dimension Fixing bolts Number

Tightening

torque

Lower link trav-

erse

Cat. 3: 34.5 mm

Cat. 4: 48.0 mm

Cat. 5: 56.0 mm

M20 8.8 8 410 Nm

Ball coupling

K80 (LI009) 82 mm M16 10.9 8 300 Nm

K80 (LI040) 82 mm M20 10.9 8 560 Nm

K80 (LI015) 82 mm M20 10.9 12 560 Nm

Drawbar eye

D35 (LI038) 36.5 mm M16 12.9 6 340 Nm

D40 (LI017) 41.5 mm M16 10.9 6 300 Nm

D40 (LI006) 42.5 mm M20 8.8 8 395 Nm

D46(LI034) 48 mm M20 10.9 12 550 Nm

D50 (LI037) 51.5 mm M16 12.9 4 340 Nm

D50 (LI010) 51.5 mm M16 10.9 8 300 Nm

D50 (LI012) 51.5 mm M20 10.9 4 540 Nm

D50 (LI011) 51.5 mm M20 8.8 8 410 Nm

D50 (LI030) 52.5 mm M20 8.8 8 395 Nm

D51 (LI039) 53 mm M20 10.9 12 600 Nm

D58 (LI031) 60 mm M20 10.9 12 550 Nm

D62 (LI007) 63.5 mm M20 10.9 8 590 Nm

D79 (LI021) 81 mm M20 10.9 12 550 Nm

Loading...

Loading...