PN 903-8797, Rev A

Specications

These performance characteristics are based on operation with factory-set

conguration parameters.

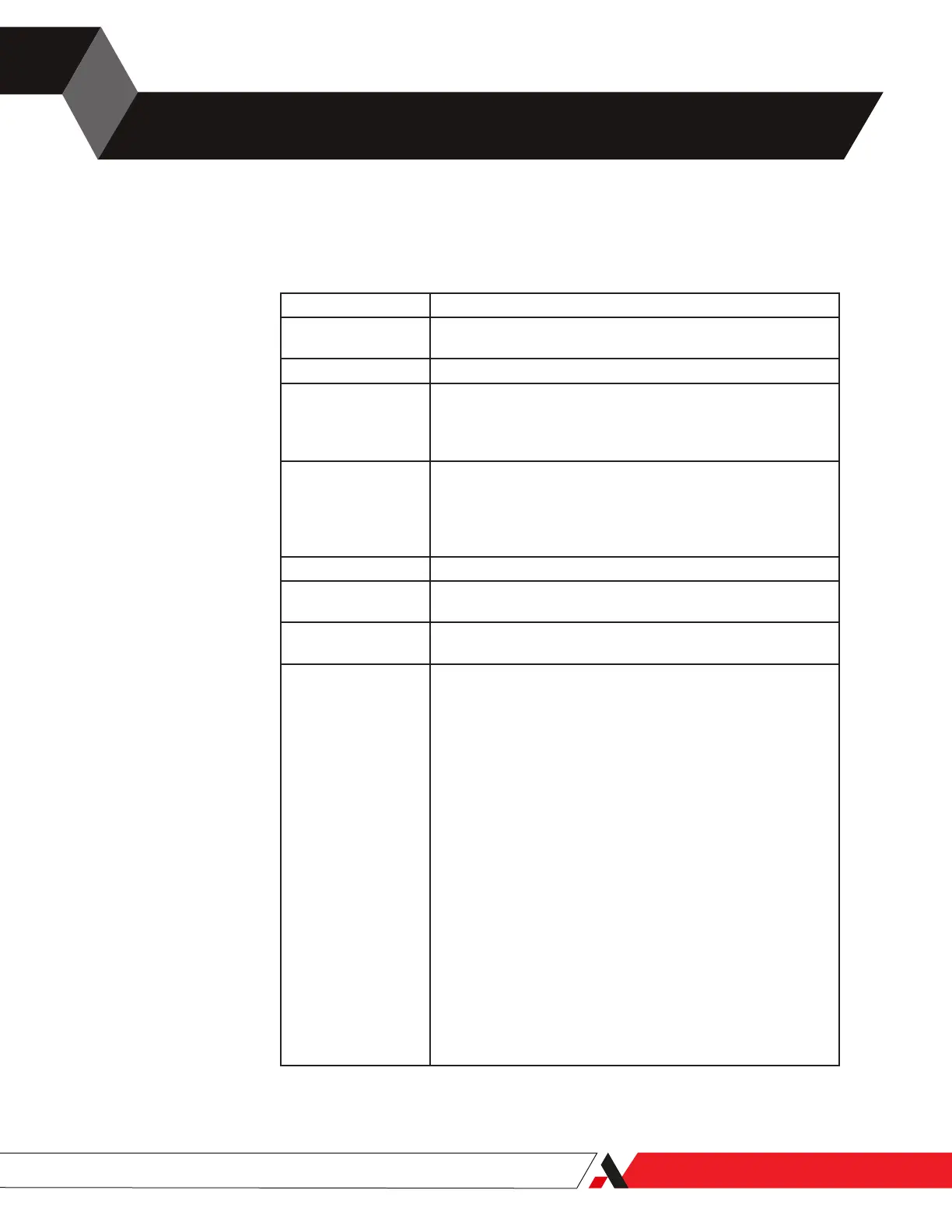

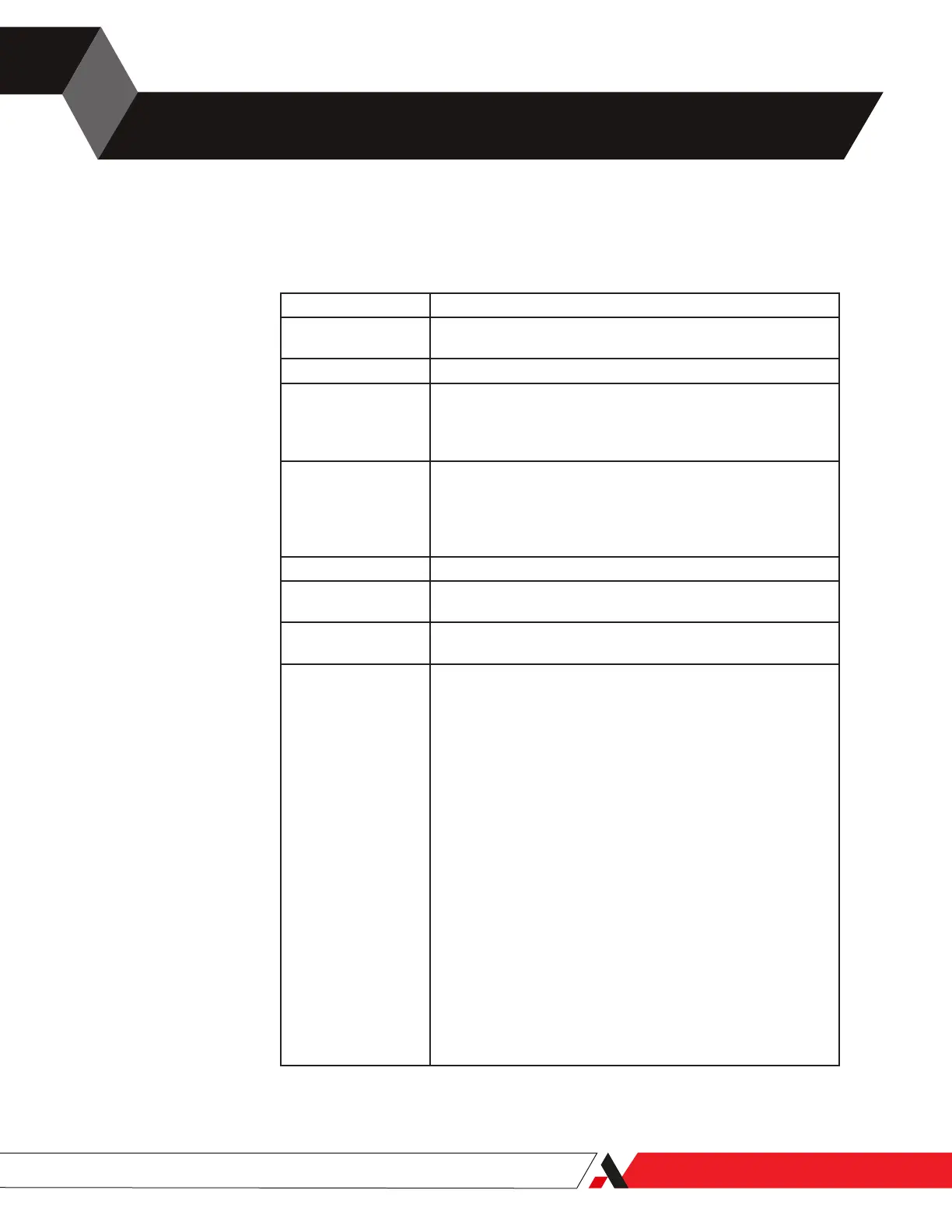

Specication Description

Standard Ranges For application of sweet (H

2

S <50 PPM) natural gas. The

composition of the gas must be above the upper explosive limit.

Methodology Chilled-mirror technique.

Speed of Response 2 °C per minute (typical cooling rate), with cycle time typically

20–30 minutes.

Actual response time will vary based on process conditions, the

cooling rate, pressure, and the temperature of the last dewpoint.

Accuracy Hydrocarbon Dewpoint temperature:

±1 °C (±2 °F) with laboratory-grade propane.

Accuracy is determined by using pure propane and comparing the

measured results with that from published vapor pressure data for

propane.

Repeatability ±0.4 °C (±0.7 °F)

Sensitivity ±0.1 °C (±0.2 °F)

This is for the stability of temperature measurement only.

Maximum Water

Content

500 mg/m

3

(equivalent to a +5 °C water dewpoint at 200 PSIG)

Customer Connections Analog Outputs

4 isolated 4–20 mADC self-powered (standard) or loop powered

(optional).

Self-Powered: Congured as a 2-wire transmitter,

compatible with a loop impedance of

0–1000 ohms.

Loop-Powered: 1500 Vrms isolated analog output

congured as a 2-wire transmitter. An

external power supply (15–30 VDC) capable

of supplying 25 mA per loop is required

(supplied by customer). When 30 VDC is

supplied, the maximum loop impedance is

1000 ohms.

6 independent sets of SPDT Form C, dry (potential free) relay

contacts, 24 VDC, 0.5 A maximum

Digital Communication

Local Service Port: RS-232

Remote Service Port: RS-422/RS-485 (2-wire or 4-wire) using the

optional serial communications, Modicon

Modbus® protocol, or using the optional

System 200 Congurator Software installed

on a laptop computer.

Specications | 5-1

Loading...

Loading...