PN 903-8797, Rev A

Sample System Volume and Flow Rates

The sample gas ow rate during the Purging/Hold Stage is controlled by the

pressure regulator. The regulator may be set for the desired gas ow rate by

temporarily installing a ow metering device (e.g., a rotameter – supplied by

the customer/end user) on the Vent Line between the Filterblock Assembly

and the used gas disposal location.

The rotameter can be a permanent installation if it is rated and ap-

proved for the pressure it will be exposed to when the Vent Line is

closed o. (Example, if the Vent Line is closed, the rotameter must be

able to withstand the pressure of the process line.)

If the rotameter being used cannot withstand the process gas line

pressure, it must be a temporary installation only; the rotameter must

be removed before running the analyzer under normal operating

conditions.

When determining the purge ow rate to use, the line pressure, purging time,

and sample system volume should all be considered.

The dierence in pressure between the Measuring Cell and the ow metering

device must also be considered. The volume of the Measuring Cell is 7.3 mL;

the volume of the Measuring Cell, lter, and interconnecting line is approxi-

mately 23 mL. The volume of the remainder of the sample system can be

estimated from the length and inner diameter of the Sample Line. The volume

of 0.25-inch tubing having 0.035-inch wall thickness is 16.4 mL/m (5.0 mL/ft).

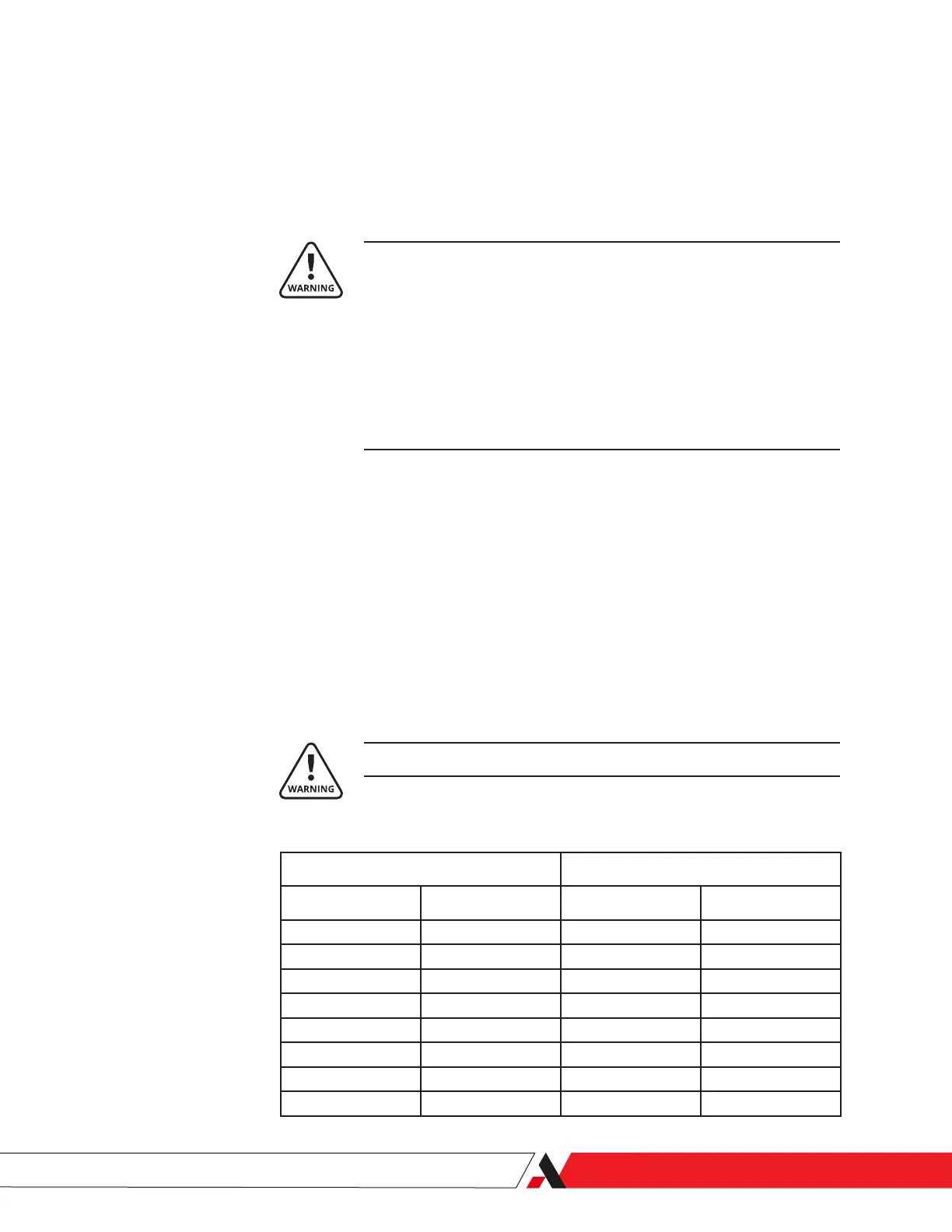

The maximum suggested purge ow rates for various sample gas pressures are

listed below.

Do not exceed the pressure rating of the ow metering device.

Sample Gas Absolute Pressure Suggested Maximum Purge Flow Rate

KPA PSI L/minute SCFH

700 100 1.0 2

2000 290 2.0 4

3000 435 2.5 5

4000 580 3.0 6

5000 725 3.5 7

7500 1088 5.0 10

10000 1450 7.5 15

13790 2000 10.0 20

Installation and Start-Up | 2-39

Loading...

Loading...