PN 903-8797, Rev A

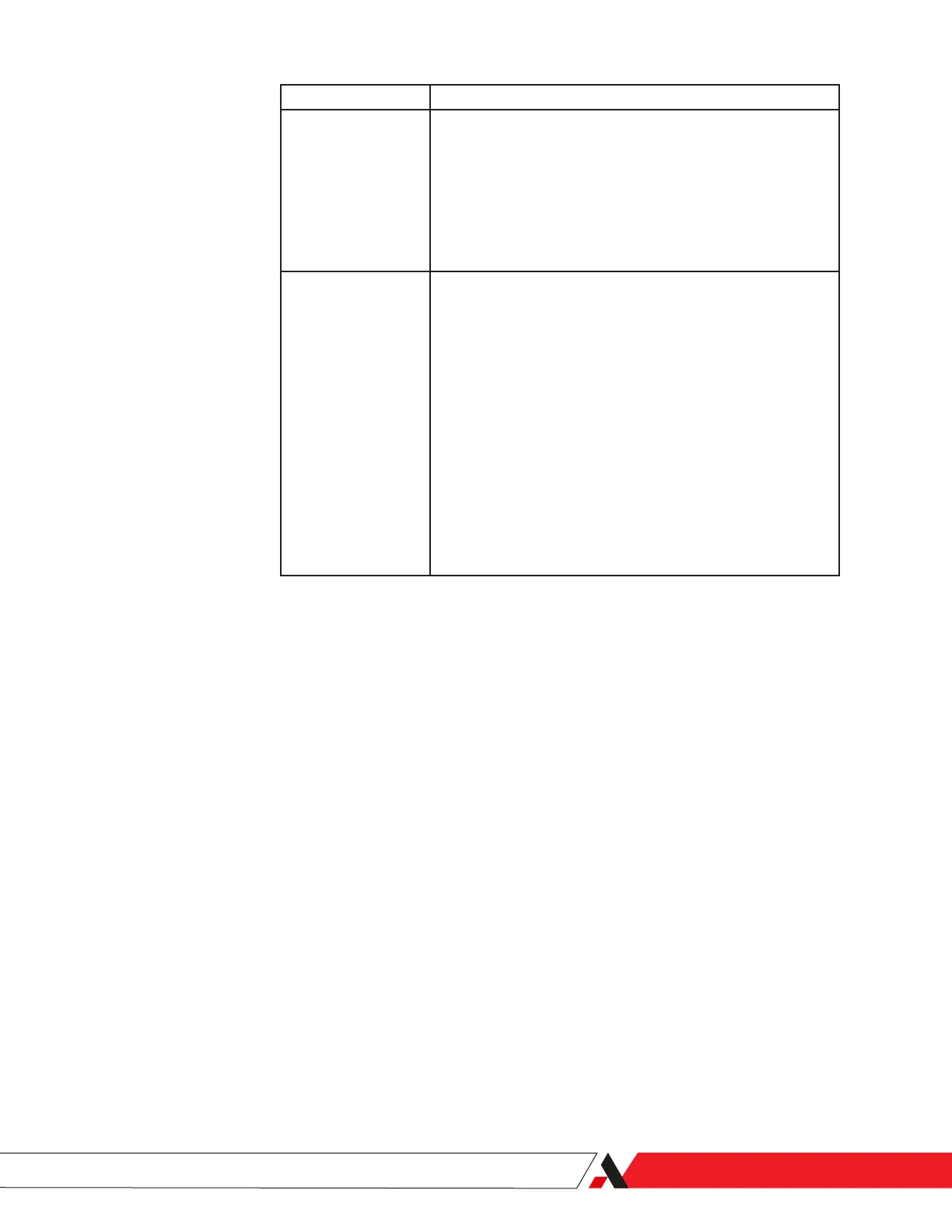

Specication Description

Minimum Clearances Heat Dissipation

To allow for heat dissipation and servicing, the required minimum

clearances are:

- 150 mm (6") each side

- 75 mm (3") top and bottom

- 900 mm (36") front

Door Swing

To allow for full door swing, minimum clearance in front of the

analyzer is approximately 574 mm (22.6").

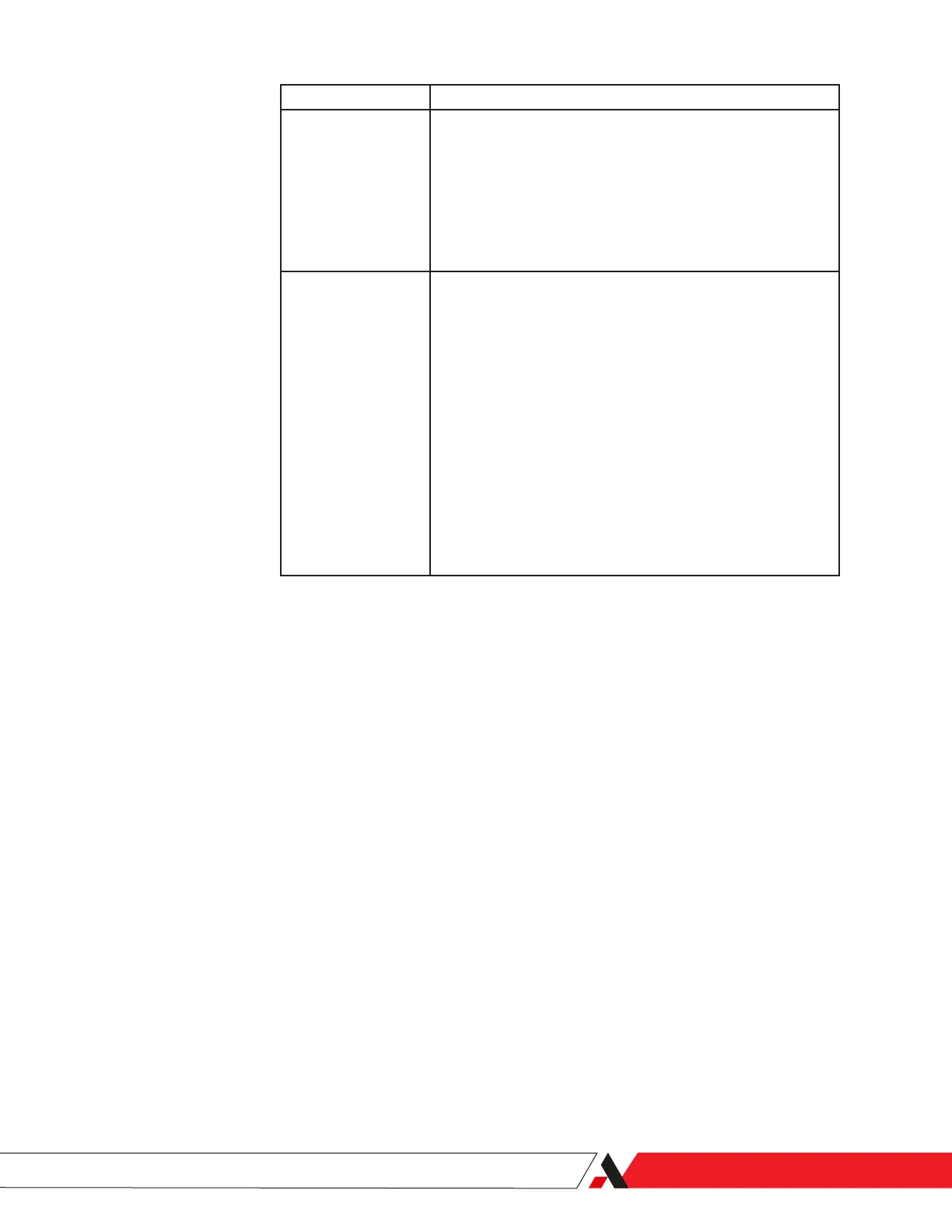

Dry Gas Supply (Purge

Air)

A dry atmosphere within the Thermoelectric Cooler (TEC)

compartment is necessary to prevent ice from forming, which can

damage the cooler. A dry atmosphere can be created by connecting

the Flame Arrestor Fitting on the Cooler Housing to a purge gas

supply (typically N2) or to a dry gas supply – such as air – with a

water dewpoint temperature less than -40 °C (-40 °F) and a ow rate

less than 15 L/day (0.53 CFD). The purge gas pressure upstream of

the Flame Arrestor Fitting cannot exceed atmospheric pressure by

more than 1 PSIG (70 mBAR). (Dry gas supplied by the customer/

end user.)

Caution:

Before operating the 241CE II Analyzer, a Flame Arrestor

Fitting must be installed on the Cooler Housing (to a dry

gas supply). This tting and an associated Flow Restrictor

is supplied by AMETEK. Failure to install a dry gas supply

meeting these specications voids the warranty of the Peltier

Cooler.

Specications | 5-3

Loading...

Loading...