PN 903-8797, Rev A

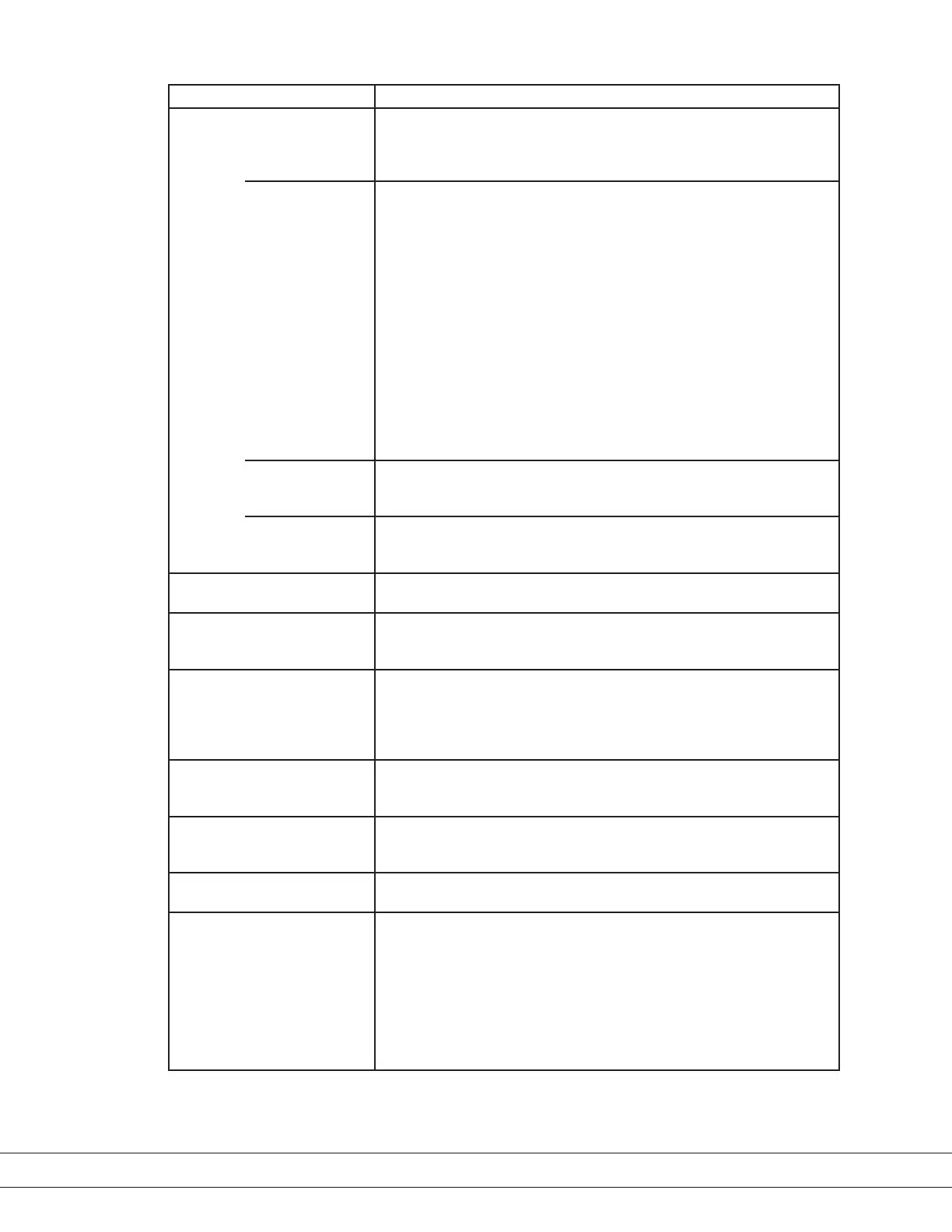

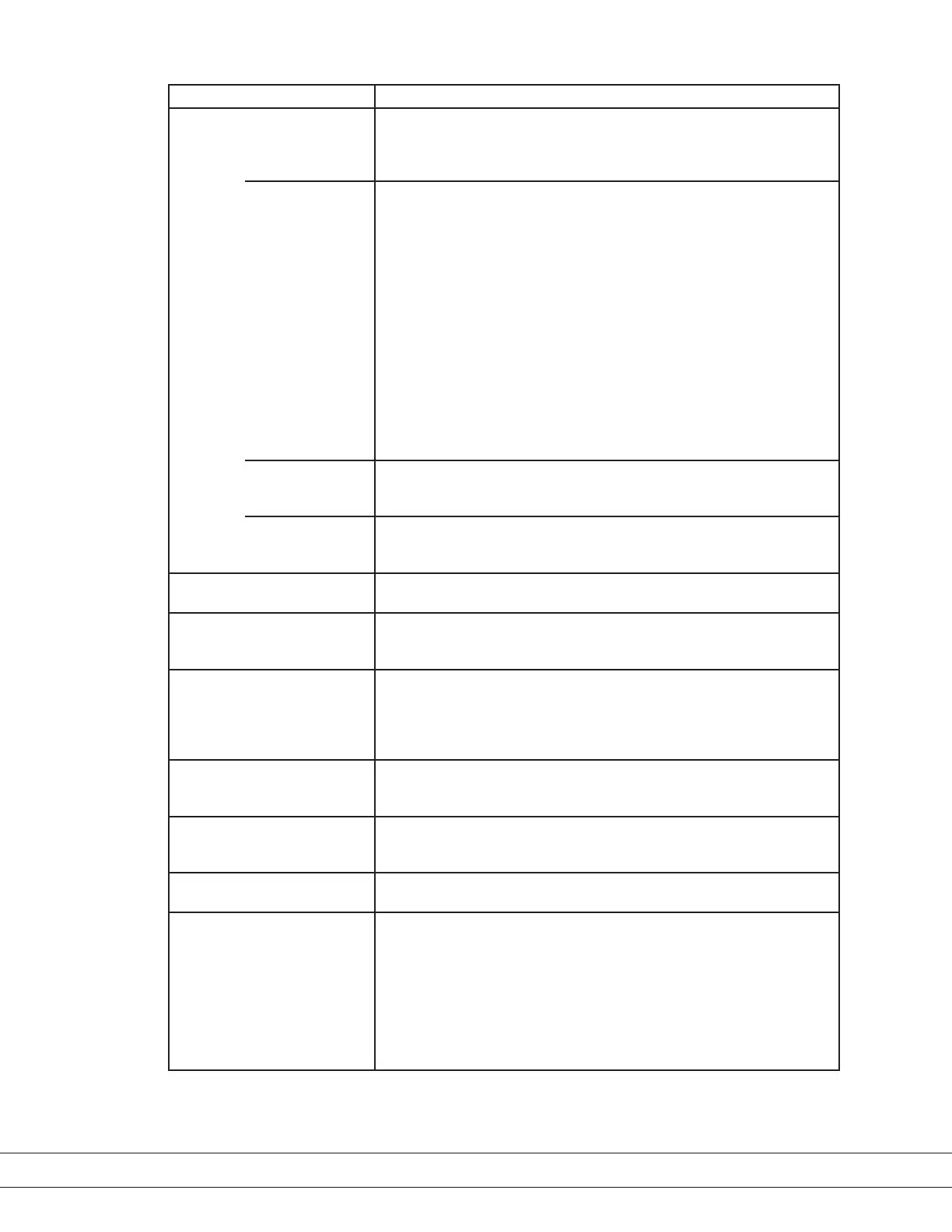

Component Function

Heatsink Absorbs heat from the Mirror during the Cooling Stage. The heat is then

transferred to the atmosphere through the Heatsink ns. During the Warming

Stage, the Heatsink serves as a passive source of heat by using the surround-

ing ambient temperature to heat the mirror.

Optical Systems The 241CE II Analyzer employs two Optical Systems in its Measuring Cell:

• One detects hydrocarbon condensation on the rough, black surface.

• One detects water condensation on the smooth, reective surface. (This

water dewpoint measurement is for internal use only, used for compensa-

tion in the calculation of HCDP measurements.)

For each optical system, light from a light-emitting diode (LED) is directed to

a mirror surface through a Polycarbonate Window. The optic-path windows

are truncated cones and thus will remain seated rmly even with high-

pressure gas samples in the Measuring Cell. The placement of the optic-path

windows and Phototransistors are not symmetric, as suggested by Figure 1-3.

These elements are located, by design, so that when condensation occurs

– either hydrocarbon on the rough surface, or water on the smooth surface –

the intensity of light at the respective phototransistor increases. This arrange-

ment is possible because of the dierent wetting properties of the two types

of liquids.

O-ring The gas sample chamber is formed by the Mirror Support and the cavity

machined within the aluminum cylinder. The gas seal between the two parts

is created by an o-ring.

Sample Inlet/Outlet The Sample Gas Inlet and Outlet channels are simply bored through the alu-

minum cylinder. Both the Sample Inlet and Outlet connections contain ame

arrestors.

Pressure Regulator Used to adjust the sample gas ow rate. This regulator is labelled “Flow Ad-

justment” on the analyzer backpan.

Purge Air (Gas) The purge air (gas) supply creates a dry atmosphere within the Thermoelec-

tric Cooler (TEC) compartment to prevent ice from forming, which can dam-

age the cooler.

Purge/Shut In

Solenoid Valve

Controls the ow of the sample gas. At the start of the Purging/Hold Stage,

the solenoid valve is opened to allow the sample gas to purge through the

Measuring Cell. At the end of the Purging/Hold Stage, the solenoid valve is

closed to stop the ow and to enable the Measuring Cell to equilibrate to the

process stream pressure.

Relief Valve The overpressure Relief Valve, which is set to release at 13.8 BARG (200 PSIG),

prevents the solenoid valve from becoming over-pressurized (attaining full

line pressure) in the case of a failure of the pressure regulator.

Bypass Valve The Bypass Valve allows a small ow rate during the measuring cycle. The

ow rate through the bypass is approximately one-tenth of the Purge/Hold

Stage cycle ow (called a “trickle purge”).

Vent Line Vents the used sample gas to atmosphere or to an approved low pressure

(<50 PSIG) are header.

Electrical Leads The analyzer is controlled by a single Microcontroller board which, along

with the power supplies and other electronic components, is contained in an

enclosure separate from the Measuring Cell Assembly (Figure 1-4). Communi-

cation between the Microcontroller board and the Measuring Cell Assembly

is via Electrical Leads which pass through the Measuring Cell seal mounting

assembly. The Microcontroller monitors the mirror temperature, controls the

mirror cooling rate, adjusts the brightness level of the LEDs, monitors the

light intensities at the phototransistors, controls the sample valve, and deter-

mines whether a dewpoint is detected.

1-8 | 241CE II Hydrocarbon Dewpoint Analyzer

Loading...

Loading...