SH-300

User’s Manual Software Part

Page 51 of 103

2.8 Operation Example

Subject: The Drying Boxes Control System

Control requirements:

(1)Via SH-300 to monitor the work status of three groups of heating units;

(2)Via SH-300 to observe the actual temperature and change the preset temperature of the

drying boxes;

(3)Via SH-300 to observe the actual speed and change the preset speed of the motor;

(4)Via SH-300 to set alarm information of abnormal work;

Operation Procedure:

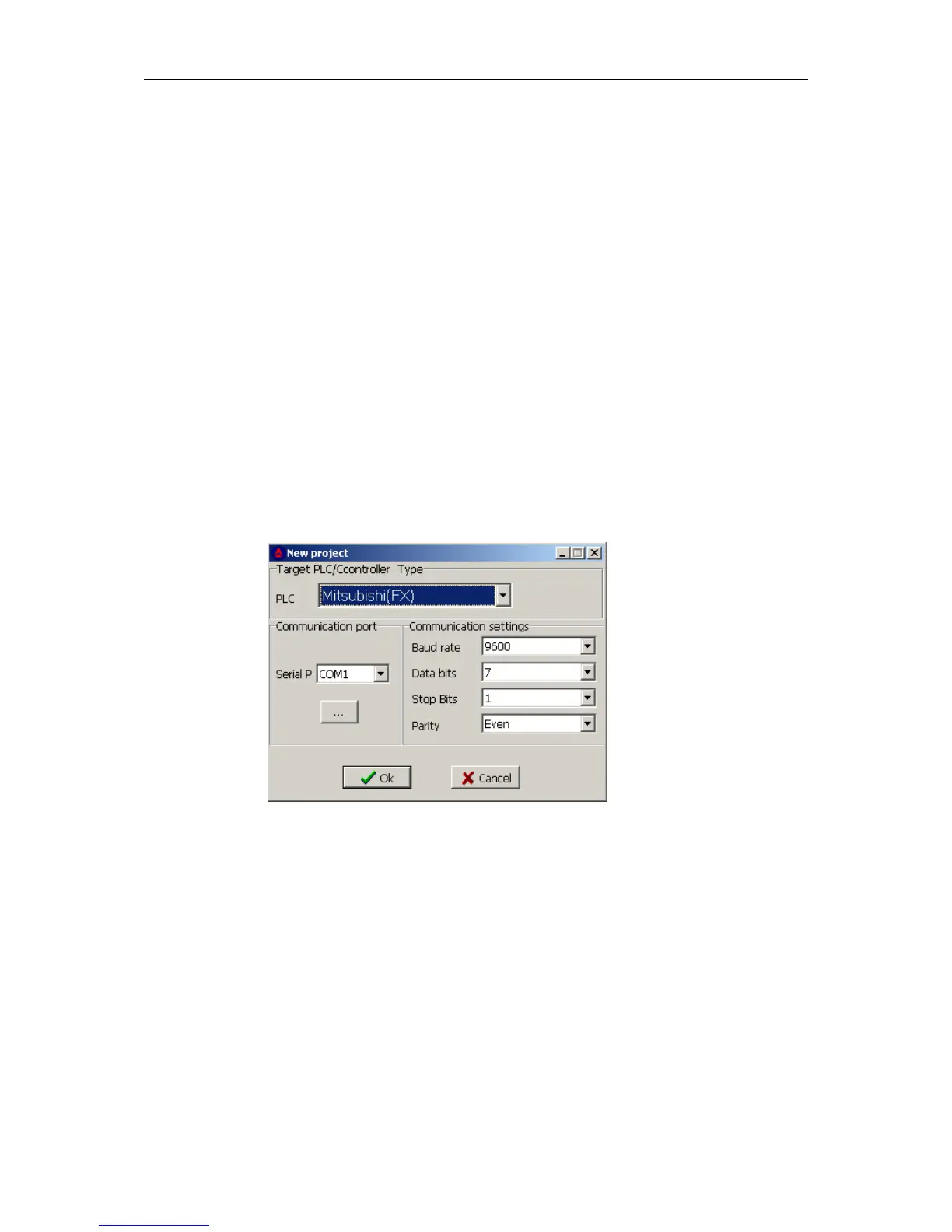

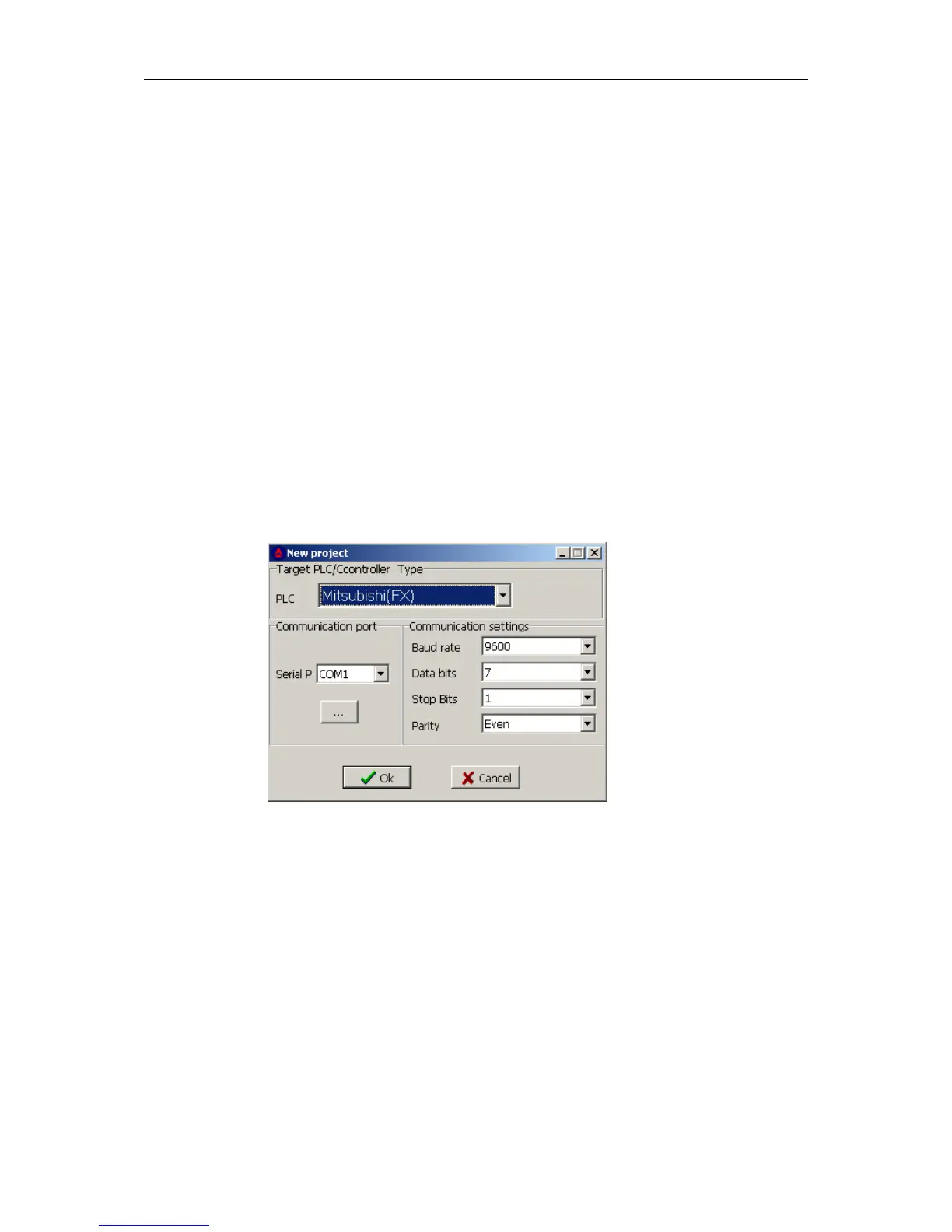

1. Open SH300 software and click “New Project”, a prompting dialogue frame will be shown as

follows:

Select PLC type (take Mitsubishi (FX) for example), COM port and the other corresponding

parameter and then click OK to confirm.

2. Make the main Screen 1 “Drying Box Control Menu” and input the text “Drying Box Control

Menu” in the screen description bar.

Set function key ①, set its property for jumping to Screen 2 and input the text “Temp” for

temperature setting on its right;

Set function key ②, set its property for jumping to Screen 3 and input the text “State” for state

monitoring on its right;

Set function key ③ , set its property for jumping to Screen 4 and input the text “Motor” for motor

setting on its right;

Input the text “【ALM】Alarm list” which can prompt user to press ALM key to enter alarm list

bar.

Loading...

Loading...