4 August 2016

www.ascbp.com

Light Gauge Metal Roof and Wall Panels

Installation Guide for Delta Rib

™

, Delta Rib

™

III, Nor-Clad

®

, Strata Rib

®

& 2½ Corrugated

Roof Preparation

ASC’s Light Gauge Roofing can be used in both

new construction and retrofit roofing applications. We

recommend the installation of Light Gauge Roofing over

a continuous rigid substrate such as plywood, wood

decking, or over in ter mit tent supports. Contact ASC for

additional information.

The following steps need to be taken to prepare the roof

for installation of Light Gauge Roofing panels:

New Roofs:

1. Make sure there are no nails or other objects

protruding from the substrates that might puncture the

underlayment or the roof panels. Clean all debris from

the roof.

2. Check all details for possible roof penetrations

which must be added to the deck prior to roof panel

installation.

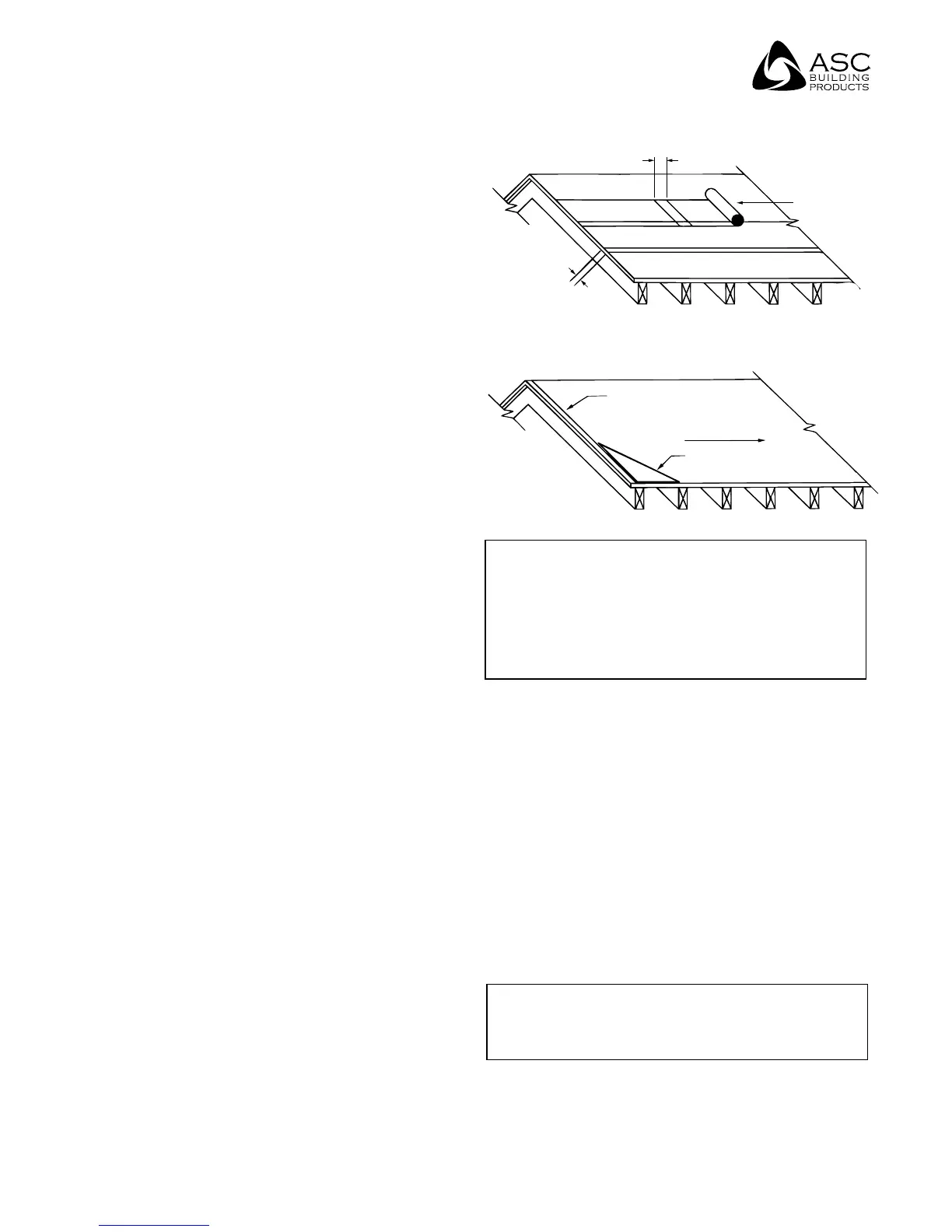

3. Cover the entire roof deck with a minimum of 30

lb asphalt-saturated felt paper. Some synthetic

underlayments may be used in place of felt with our

roofing. Installer must ensure they meet the minimum

standards of 30 lb felt and that the manufacturer

has approved them for use with metal roofing. For

applications over spaced framing other types of

moisture barriers may be required. Begin at the eave

and roll the felt horizontally (parallel to the eave).

Allow each con sec u tive course to overlap the previous

one 3 inches. Overlap the end a minimum of 6" when

starting a new roll of felt. Areas of felt paper that have

been torn or cut should be replaced or repaired prior

to installation of the metal roof. (See illustration #1).

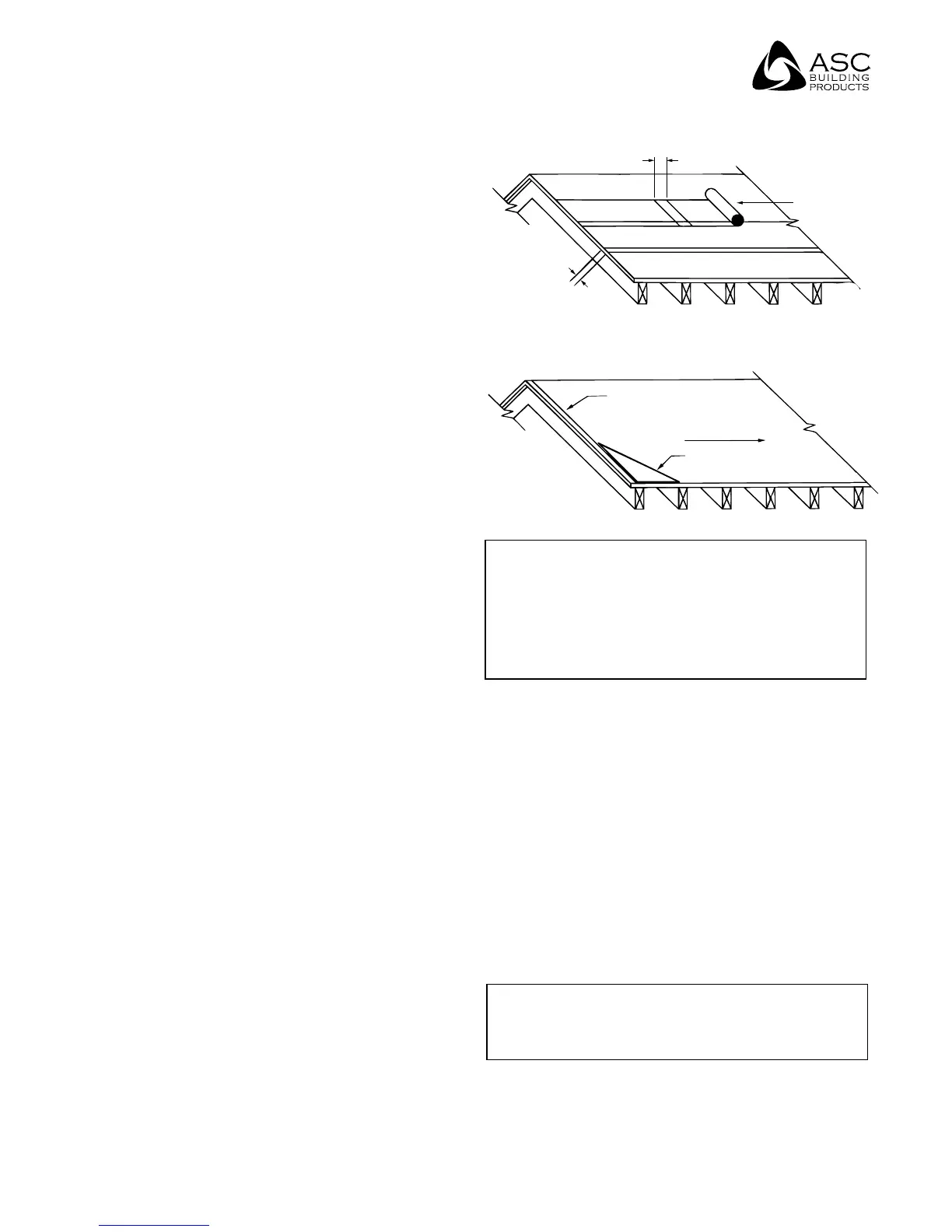

4. Place an alignment line along the gable end where

the first roof panel will be installed. This line must

be parallel to the gable edge of the roof deck

and square with the eave line. Check the roof for

squareness by making a 3' line across the eave. (See

illustration #2).

Completing the 3' x 4' x 5' triangle should place the 4'

edge of the triangle parallel with the gable. The first

roof panel will be placed parallel with this line. Slight

variations or out-of-square conditions up to 3" can be

covered by the gable trims shown on page 18.

5. It is very important to measure the entire length of

the roof from gable to gable. Correct placement

of the panels will allow the panel’s ribs on each

side to be covered by the gable flashing shown on

page 18. This will create a symmetrical appearance

on both gables. Should this be impractical, the

adjustable gable detail on page 29 can be used.

3" SIDE LAP

30# FELT PAPER

ILLUSTRATION #1

ILLUSTRATION #2

ALIGNMENT LINE

DIRECTION OF

PANEL APPLICATION

3' x 4' x 5' TRIANGLE

4'

5'

3'

Note:

In areas where snow, ice, and heavy rain conditions exist,

a high temperature cold-applied rubberized underlayment

should be used in lieu of felt in the valleys. Felt on the

remainder of the roof will lap over the membrane where

the two meet. See Valley page 13.

Existing Roofing:

Some jurisdictions will allow reroofing over existing roofing

without the need for tearoff. Check with your local codes

or building department for your specific requirements.

For best results, Light Gauge Roofing requires a relatively

smooth and flat substrate. Application over rough and/or

uneven surfaces is not recommended, for example, wood

shingles.

If the roof is to be stripped down to the existing decking,

follow the procedures for new roofs on page 4. Be sure to

check the existing roof and repair any damaged areas prior

to installation of the new roof system.

Note:

Do not apply Light Gauge Roofing over roofs with

structural damage or trapped moisture.

Loading...

Loading...