Installation

WARNING Hot hydraulic oil squirting out

The hydraulic system is under high pressure. If

hydraulic connections come loose or are

disconnected, hydraulic oil will squirt out under

high pressure. Hydraulic oil squirting out can lead

to serious injury.

►

Depressurise the hydraulic system before

connecting or disconnecting the hydraulic

circuits of the hydraulic attachment (see chapter

Depressurising the hydraulic system).

WARNING Risk of death due to defective

first installation and commissioning

Faults during the first installation or commissioning

can lead to life-threatening situations and may

cause considerable damage to property.

►

Have the first installation and commissioning

exclusively conducted by authorised specialist

personnel.

►

Do not undertake unauthorised first installation

and commissioning.

Media/consumables

The following consumables are used when

operating the hydraulic attachment:

Mineral hydraulic oil

All hydraulic oil brands prescribed by the carrier

manufacturer are also suitable for use when

operating the hydraulic attachment.

However, the oil should comply with viscosity class

HLP 32 or higher.

In summer and in hot climates, oils of viscosity

class HLP 68 or higher should be used.

In all other respects the regulations of the carrier

manufacturer are to be taken into consideration.

Optimum viscosity range = 30 - 60 cSt

Max. start viscosity = 2000 cSt

Max. oil temperature = 80 °C

Special conditions apply to using the hydraulic

attachment at low temperatures (see chapter Low

ambient temperature).

◆

Check the oil filter!

An oil filter must be integrated in the tank line of

the hydraulic system. The maximum mesh

width allowed for the oil filter is 50 microns; it

must have a magnetic separator.

Non-mineral hydraulic oil

NOTICE Mixed hydraulic oil

Never mix mineral and non-mineral hydraulic oils!

Even small traces of mineral oil mixed in with non-

mineral oil can result in damage to both the

hydraulic attachment and the carrier. Non-mineral

oil loses its biodegradability.

►

Only use one type of hydraulic oil.

If you are using non-mineral oil it is imperative that

the name of the oil in use be indicated when

returning the hydraulic attachment for repair.

In order to protect the environment or on technical

grounds, hydraulic oils are currently being used

which are not classified as HLP mineral oils.

Before using hydraulic oils of this kind it is

imperative to ask the carrier manufacturer whether

operations with such fluids are possible.

Our hydraulic attachments are basically designed

for use with mineral oils. Consult the Atlas Copco

Customer Center/Dealer in your area before using

other hydraulic oils approved by the carrier

manufacturer. Following initial assembly and after

any workshop repairs, our hydraulic attachments

are subjected to a test run on a test bed powered

by mineral oil.

Gear oil

Media /

consumables

Temperature range Part number

AC Fluid Traction

Gear 100

-15 to +40 °C

5 l (1.32 gal)

4812 0082 71

20 l (5.28 gal)

4812 0082 72

209 l (55.21 gal)

4812 0082 73

AC Fluid Gearbox

100

-20 to +30 °C

5 l (1.32 gal)

4812 0082 74

20 l (5.28 gal)

4812 0082 75

209 l (55.21 gal)

4812 0082 76

Preconditions for the carrier

The carrier must fulfil the following criteria in order

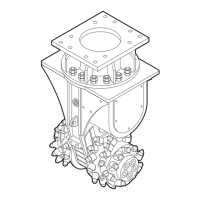

that a transverse drum cutter can be attached to it:

•

A complete hydraulic hammer or shearer line

right to the end of the carrier boom must be

available.

•

The motor's pressure line is set to max. 350

bar.

•

The pressure of the tank line is at least 5 bar

above the pressure of the case drain line.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

24 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Loading...

Loading...