◆

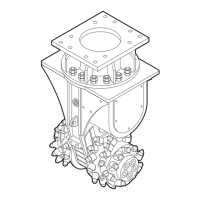

Carefully loosen the oil filler screw (A) using an

Allen key and allow any pressure in the gear to

drop.

Any available oil pressure will drop.

◆

Fully unscrew the oil filler screw (A).

Note: It is important that the oil filler screw (A) is

unscrewed first. This allows the oil to run off

more quickly and effectively.

◆

Loosen and unscrew the oil drain plug (B) using

an Allen key.

Note: The oil drain plug (B) is located exactly

opposite the oil filler screw (A).

◆

Allow the oil to fully drain off.

◆

Clean the oil drain plug (B) and opening with a

cotton cloth.

Note: The oil drain plug (B) and oil filler screw

(A) are fitted with a magnet that attracts metal

filings.

◆

Check the oil drain plug (B) for metal particles,

if necessary remove.

◆

Screw in the oil drain plug (B) and tighten using

an Allen key.

◆

Dispose of used oil in accordance with the

applicable environmental regulations.

Fill up gear oil

◆

Clean the oil filler opening with a cotton cloth.

◆

Fill up gear oil as per the specifications (see

chapter Media/consumables). Gear oil volumes

(see chapter Technical specifications).

Note: It is important to fill until the oil is level

with the oil filler screw with the transverse drum

cutter in a vertical position (cutter drums down).

Always check that the system has been

correctly filled with the transverse drum cutter

installed on the carrier.

◆

Clean the oil filler opening with a cotton cloth.

◆

Screw in the oil filler screw and tighten using an

Allen key.

◆

Clean the transverse drum cutter (see chapter

Cleaning).

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

43

Loading...

Loading...