Follow the safety and operating instructions of

the carrier when connecting the leakage oil line

to the hydraulic oil tank.

◆

Attach the leakage oil line to the pre-installed

connection on the hydraulic oil tank and tighten

with the required tightening torque.

◆

Install the leakage oil filter at an appropriate

location on the carrier.

Making the hydraulic connections

NOTICE Faulty hydraulic installation

The carrier must have a suitable hydraulic

installation to operate the hydraulic attachment.

Improperly installed lines and incorrectly rated

sizes may cause the oil to heat up and the

hydraulic attachment to be damaged.

►

Only use hydraulic lines of the rated sizes as

instructed (see chapter Technical

Specifications).

►

Check the rated size of the hydraulic lines on

existing hydraulic installations! All supply and

return lines for the hydraulic oil must have a

sufficient inside diameter and wall thickness.

►

Route all hydraulic hoses in a torsion-free

manner.

◆

Switch off the carrier.

◆

Depressurise the hydraulic system according to

the manufacturer's safety and operating

instructions for the carrier.

◆

Close all shut-off valves in the installation at the

boom, if no quick couplings are used.

NOTICE

Damage to hydraulic parts

Polluted hydraulic lines and connections may

enable sand, fragments of material and dirt to

penetrate the hydraulic attachment and damage

the hydraulic parts.

►

Clean the hydraulic lines and connections prior

to connecting the hydraulic lines.

◆

Have dirty hydraulic lines rinsed through by a

specialist company.

◆

Clean dirty hydraulic line connections with a

suitable grease-dissolving universal cleaner.

◆

Observe the cleaner manufacturer's information

on safety and use.

NOTICE Property damage due to unauthorised

removal of the check valve

Removing the check valve from the tank line of

hydraulic hammer systems leads to destruction of

the hydraulic motor of the transverse drum cutter.

►

Never remove the check valve from the tank

line of hydraulic hammer systems.

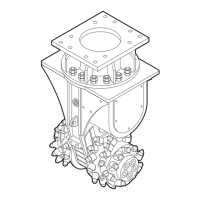

The transverse drum cutter is supplied with 3

hydraulic hoses, already installed by the

manufacturer:

•

Pressure line to the transverse drum cutter

•

Tank line with check valve to the carrier

•

Leakage oil line to the carrier

Note: Installation of a hydraulic circuit suitable for

operating a transverse drum cutter on the carrier is

the responsibility of the operator. The actions and

safety requirements pertinent to this can be found

in the carrier's operating manual.

For operation of the transverse drum cutter,

required adjustments (pressure and hydraulic flow)

on the carrier are the responsibility of the operator.

•

Consult, for installation to a carrier with

hydraulic hammer system, installation plan 1

(see chapter Hydraulic installation version 1 for

hydraulic hammer).

•

Consult, for installation to a carrier with

hydraulic shear system, installation plan 2 (see

chapter Hydraulic installation version 2 for

hydraulic shear systems).

Note: If it is necessary to remove the check valve,

e.g. when connecting to a hydraulic shear system

for backwards and forwards rotation, it is

necessary to guarantee that the pressure in the

tank line is at least 5 bar higher than that in the

leakage oil line at all times. This pressure

differential must be measured, documented and

communicated to Atlas Copco to prevent the

warranty on the hydraulic motor becoming null and

void.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

28 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Loading...

Loading...