Maintenance schedule

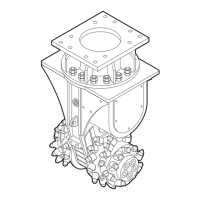

daily, before and after operation Cutter drums:

Check if all round attack picks exist.

Check the round attack picks for wear and play in the pick box.

Check the head lengths of all round attack picks for even wear.

Check the wear in pick boxes and wear sleeves.

Check charging spirals for wear.

Check cutter drums for jammed steel parts.

Note: When cutting abrasive materials (e.g. concrete, sandstone) and additional spraying of

the cutter drums with water, it is necessary to reckon with increased wear of the individual pick

boxes.

Gear:

Check for oil leaks.

Check the gear for unusual noise.

Check the tightness of threaded connections.

Check wear plates for wear.

Hydraulic motor:

Check for oil leaks.

Check for overheating.

Check the hydraulic motor for unusual noises.

Check the tightness of threaded connections.

Rotatable upper part:

Check the tightness of threaded connections.

Check the rotatable upper part for cracks.

Hydraulic hoses and fittings:

Check the hydraulic hoses for wear and leaks.

Check the fittings for leaks and tightness.

Check the leakage oil line for contamination.

Check the adapter plate for cracks.

Check hydraulic lines for leaks and damage.

Check the pipe clamp receiver on the carrier.

after shift Clean transverse drum cutter

weekly Check the bolted connections at the hydraulic lines and tighten as required.

after the first 50 operating hours Change hydraulic oil filter cartridge.

after the first 100 operating hours to be done in a workshop:

Change gear oil when you perform heavy cutting operation (e.g. reinforced concrete)

after the first 200 operating hours to be done in a workshop:

Change gear oil when you perform normal cutting operation

every 500 operating hours Check oil filter cartridge, replace if necessary.

every 1000 operating hours to be done in a workshop:

Change gear oil when you perform heavy cutting operation (e.g. reinforced concrete)

every 2000 operating hours to be done in a workshop:

Change gear oil when you perform normal cutting operation

if necessary Replace bent and damaged pipes.

Replace damaged hoses.

Check wear at the adapter plate bolts.

Replace round attack picks

to be done in a workshop:

Replace cutter drums

Replace rotatable upper part

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

40 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Loading...

Loading...