Contact the Atlas Copco Customer Center/Dealer

in your area before removing the check valve.

◆

Clean the area around the shut-off valve on the

left side of the boom.

◆

Remove the end cap from the shut-off valve on

the boom and save for future use.

◆

Unscrew the end cap from the pressure line

and save for future use.

◆

Connect the pressure line to the shut-off valve

fitting of the supply line on the left side of the

boom.

◆

Clean the area around the shut-off valve on the

right side of the boom.

◆

Remove the end cap from the shut-off valve of

the boom and save for future use.

◆

Unscrew the end cap for the tank line and save

for future use.

◆

Connect the tank line to the shut-off valve fitting

of the return line on the right side of the boom.

Note: To transport leakage oil from the hydraulic

motor of the transverse drum cutter, use the

separate leakage oil line of the carrier. If a

separate leakage oil line is not available, it is

necessary to install one ( see chapter First

installation / Install separate leakage oil line).

Installation of a leakage oil line to drain oil to

tank is the responsibility of the operator.

NOTICE Environmental damage due to

hydraulic oil

Hydraulic oil is environmentally harmful and

must not penetrate the ground or enter the

water table or water supplies.

►

Collect any hydraulic oil which escapes.

►

Dispose of it in accordance with the

applicable environmental regulations.

◆

Position an oil receiver tank beneath the

leakage oil line of the transverse drum cutter.

◆

Use a funnel to fill up the leakage oil line with

hydraulic oil until it overflows.

◆

Connect the leakage oil hose from the

transverse drum cutter onto the separate

leakage oil line of the carrier's boom.

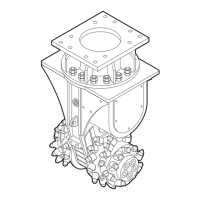

Mechanical mounting aspects

You need an assistant to attach the hydraulic

attachment to the carrier.

◆

Agree on hand signals with your assistant, to

enable him to help you placing the carrier in the

proper position to attach the hydraulic

attachment.

◆

Lower the stick of the carrier into the holder

provided on the adapter plate.

WARNING Injury by impacts

A sudden movement of the carrier may cause your

assistant to be hit and injured by the boom or the

hydraulic attachment.

►

Only move the boom very slowly and in a

controlled manner while an assistant is within

the danger zone.

►

Always keep sight of your assistant.

WARNING Hands and fingers being cut off

or hurt

Bores and surfaces can act like a pair of scissors

and cut off or hurt parts of your body.

►

Never use your fingers to check bores or fitting

surfaces.

◆

Let your assistant instruct you until the bores in

the adapter plate (B) and in the stick (A) are

properly aligned.

◆

Install the stick bolt (C) and lock it.

Loading...

Loading...