Disposal

WARNING Risk of injury due to improper

disassembly

Stored residual energy, sharp-edged parts, pointed

tips and corners on or in the machine or on the

requisite tools can cause injuries.

►

Prior to starting work ensure that there is

adequate free space.

►

Handle parts with exposed sharp-edges

carefully.

►

Ensure order and cleanliness at the place of

work! Loosely stacked or scattered parts and

tools can cause accidents.

►

Disassemble parts correctly. Be aware of the

weight of parts. These may be heavy. If

necessary use lifting gear.

►

Secure parts so that they do not fall or topple.

►

Consult the Atlas Copco Customer Center/

dealer in your area in case of ambiguities.

NOTICE Environmental damage due to

consumables

Hydraulic and gear oil are environmentally harmful

and must not penetrate the ground or enter the

water table or water supplies.

►

Collect any such consumables which may

escape.

►

Dispose of them in accordance with the

applicable environmental regulations.

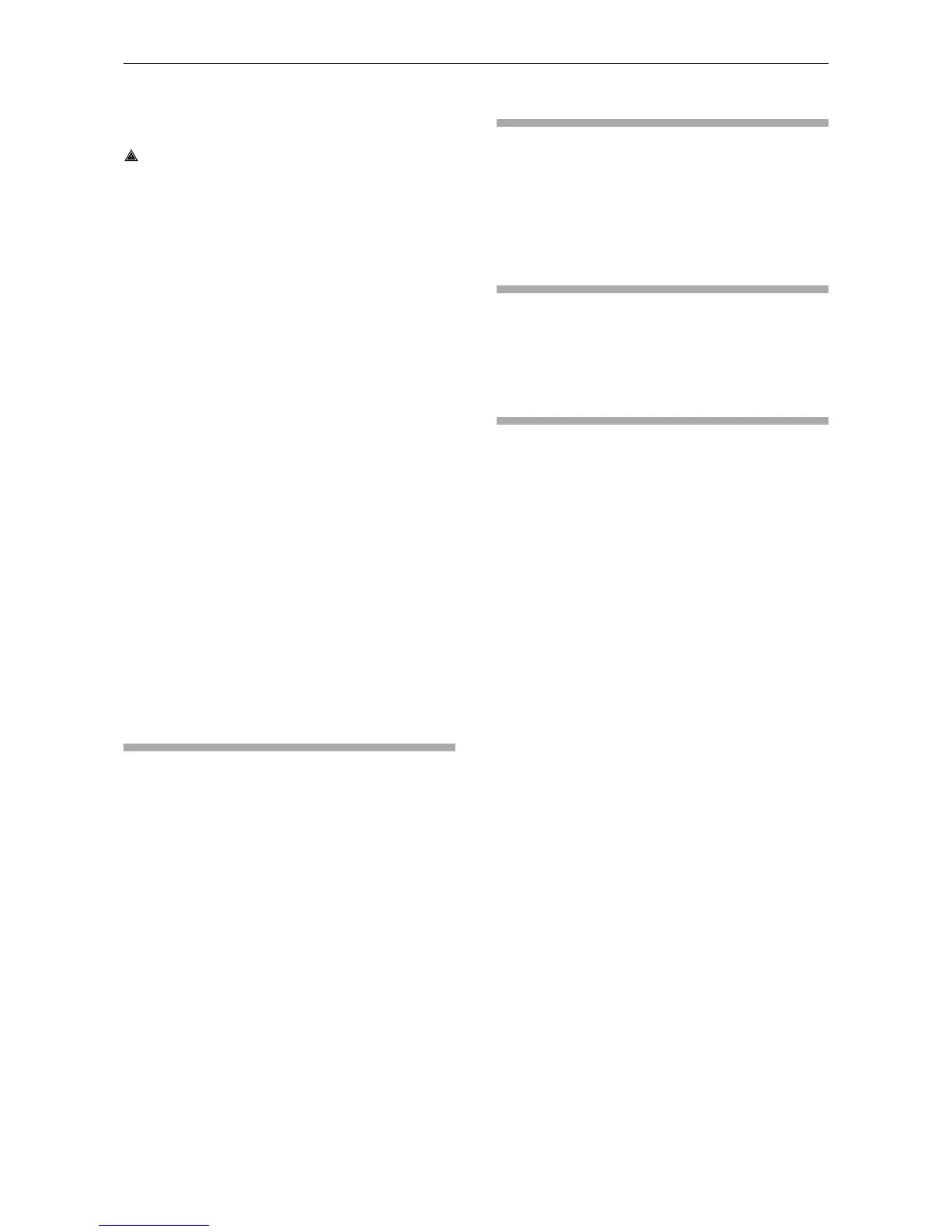

Transverse drum cutter

◆

Switch off the transverse drum cutter and

secure against a restart.

◆

Remove the transverse drum cutter from the

carrier (see chapter Removing the hydraulic

attachment from the carrier).

◆

Remove the adapter plate (see chapter

Removing the hydraulic attachment from the

carrier ).

◆

Remove the hydraulic hoses from the

transverse drum cutter.

◆

Clean the transverse drum cutter (see chapter

Cleaning).

◆

Dispose of the transverse drum cutter in line

with all applicable regulations or consult an

authorised and specialised recycling company.

Hydraulic hoses

◆

Drain the hydraulic oil from the hydraulic hoses

and collect it.

◆

Dispose of the hydraulic hoses in accordance

with the applicable regulations to avoid

environmental hazards.

Hydraulic oil

◆

Collect any hydraulic oil that escapes.

◆

Dispose of it in accordance with the applicable

environmental regulations.

Gear oil

◆

Collect any gear oil which escapes.

◆

Dispose of it in accordance with the applicable

environmental regulations.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

63

Loading...

Loading...