◆

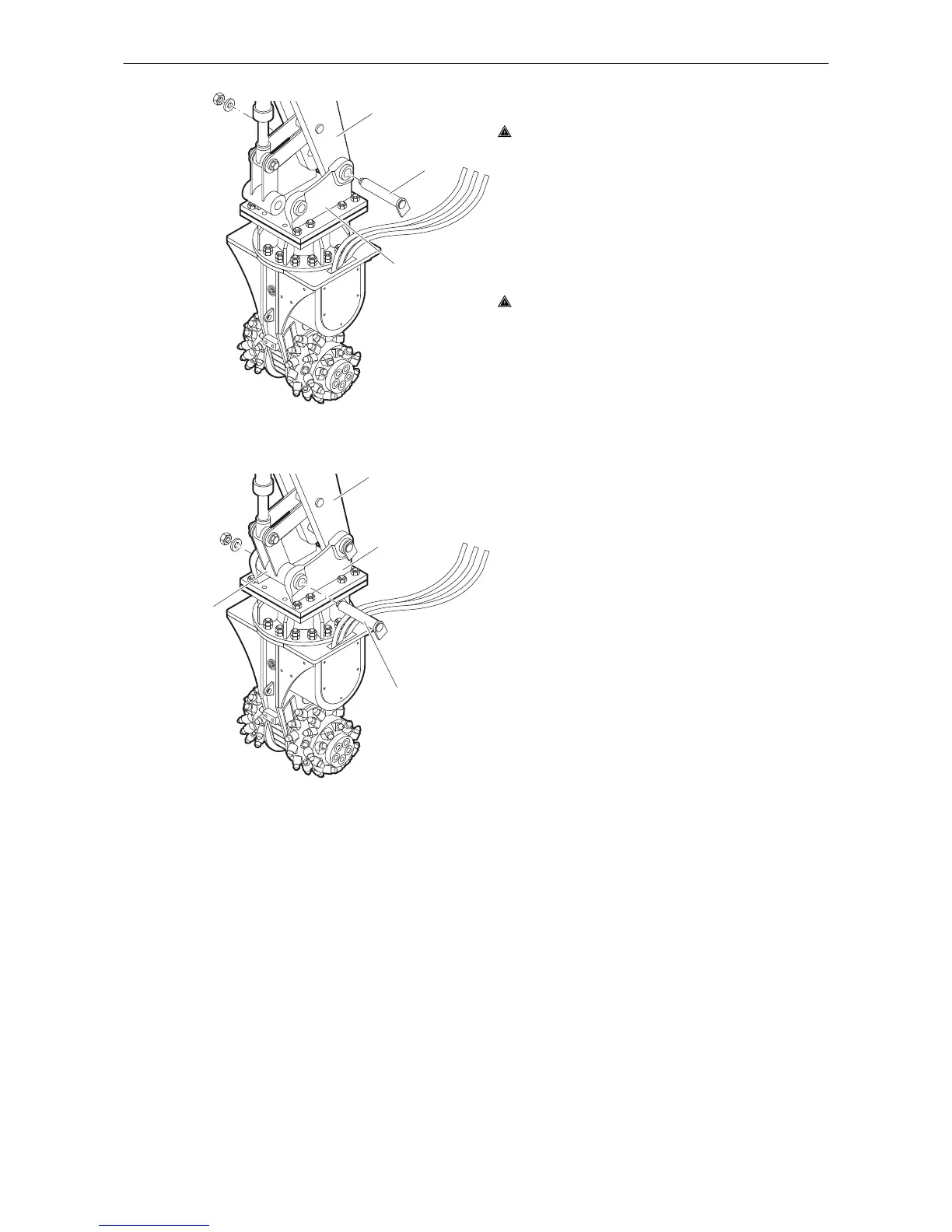

Extend the bucket cylinder until the bore in the

linkage (G) links up with the bore in the adapter

plate (C).

◆

Install the linkage bolt (F) and lock it.

◆

Carefully move the bucket cylinder into both

end positions.

The adapter plate must not be stopped by

mechanical stops in either position. Consult the

Atlas Copco Customer Center/Dealer in your area

if the adapter plate is stopped by a mechanical

stop.

First installation

WARNING Risk of death due to defective

first installation

Faults during the first installation or commissioning

can lead to life-threatening situations and may

cause considerable damage to property.

►

Have the first installation exclusively conducted

by authorised specialist personnel.

►

Do not undertake unauthorised first installation.

WARNING Unexpected movement

Sudden movements of the carrier may cause

serious injury.

►

Secure the carrier such that it cannot move

unexpectedly.

►

Observe the carrier manufacturer’s instructions.

NOTICE Damage due to incorrect oil pressure

setting

Incorrect oil pressure setting can result in severe

damage to property and the environment.

►

Before installing the hydraulic attachment to the

carrier check the oil pressure setting of

pressure line with a hydraulic flow tester.

►

Check the tank line pressure with an additional

manometer mounted between hydraulic flow

tester and tank line.

►

Ensure the technical specifications are fulfilled

(see chapter Technical specifications).

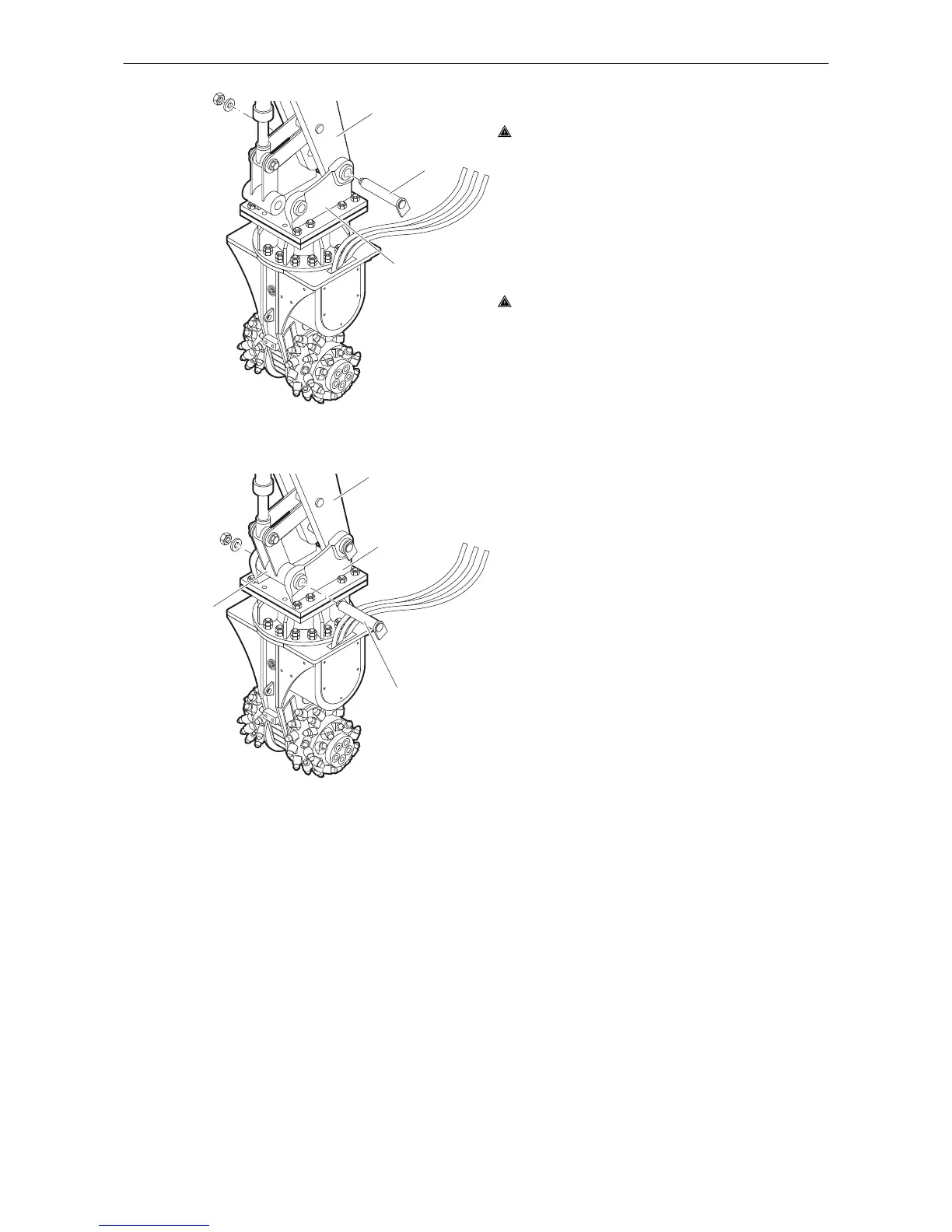

Filling hydraulic motor

Note: Prior to first commissioning the hydraulic

motor of the transverse drum cutter must be filled

with hydraulic oil (see chapter Technical

specifications).

Install separate leakage oil line

The separate leakage oil line including separate

leakage oil filter must be installed from the shut-off

valve on the boom to the carrier's hydraulic oil

tank. The operator must pre-install a suitable

connection on the carrier's hydraulic oil tank for the

leakage oil line.

NOTICE Damage due to incorrect installed

hydraulic hoses

Incorrectly installed hydraulic hoses can result in

severe damage to property and the environment.

The maximum pressure of the leakage oil line is

3 bar.

►

Install hydraulic hoses such that they always

possess sufficient play for turning and rotating

motions of the boom.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

27

Loading...

Loading...