◆

Check all bolted connections regularly for tight

fit (see Chapter Bolted connections / tightening

torques).

◆

Tighten loose bolted connections and hose

clamps to the torque required (see Chapter

Bolted connections / tightening torques).

Checking the hydraulic

attachment and adapter plate

for cracks

◆

Secure the carrier such that it cannot move

unexpectedly.

◆

Check daily, before and after operation all load-

bearing parts and welds of:

•

all the hydraulic attachment,

•

the adapter plate

for cracks.

◆

Ensure repair or refinishing in good time to

prevent greater damage.

Checking the adapter plate

bolts for wear

◆

Carry out this visual check whenever the

hydraulic attachment has been removed from

the carrier.

◆

Check the adapter plate bolts for excessive

wear such as cracks, pitting or severe erosion.

◆

Rework or replace worn bolts.

Change gear oil

The following maintenance activities are carried

out in the workshop.

The gear oil is critical for the service life of the

gear. It is also important to use the correct type

and quantity of gear oil for the transverse drum

cutter.

WARNING Risk of injury due to a failure to

observe the minimum clearances

A lack of space for assembly when changing the

oil on the transverse drum cutter inside buildings

can lead to accidents!

►

When working on the transverse drum cutter

inside buildings always ensure sufficient space

for assembly.

WARNING Risk of injury due to oil pressure

in the gear

Loosening the oil filler screw or oil drain plug on

the transverse drum cutter too quickly can result in

severe injuries.

►

Prior to all work on the hydraulic system

depressurise the complete system (see chapter

Depressurising the hydraulic system) and

safeguard it against a restart.

►

Carefully loosen the oil filler screw or oil drain

plug and wait for the pressure to drop.

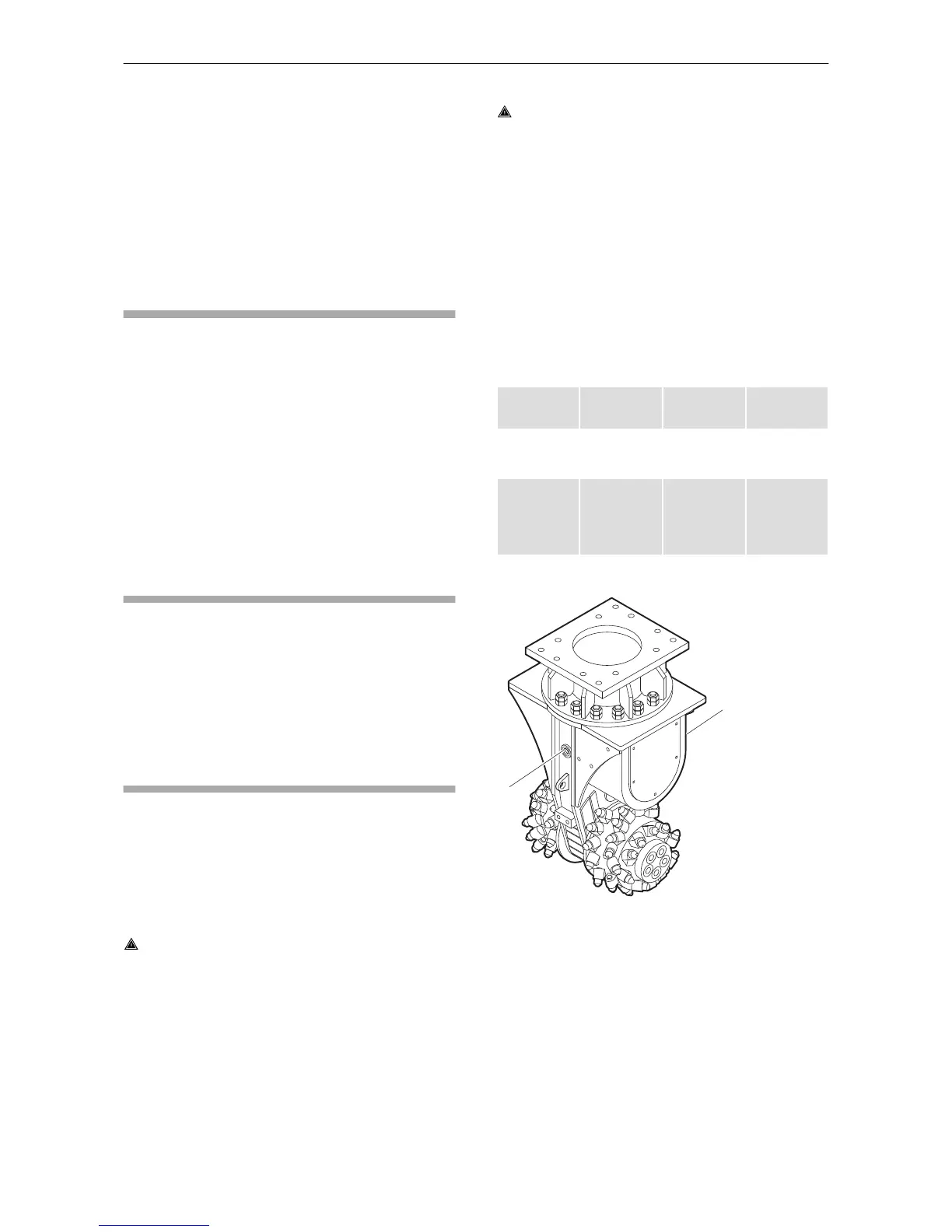

Oil change intervals

The following tables detail the oil change intervals.

Gear oil

change

1st interval 2nd interval Subsequent

intervals

With normal

cutting

operation

200 operating

hours

2000

operating

hours

Every 2000

operating

hours

With heavy

cutting

operation (e.g.

reinforced

concrete)

100 operating

hours

1000

operating

hours

Every 1000

operating

hours

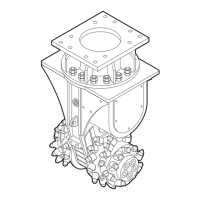

Preparation

A. Oil filler screw

B. Oil drain plug

◆

Position the transverse drum cutter horizontally

on the assembly stand.

◆

Switch off transverse drum cutter and

safeguard.

Drain off gear oil

◆

Position the oil receiver tank beneath the oil

drain plug.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

42 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Loading...

Loading...