•

The pressure in the leakage oil line is of 3 bar

maximum during operation.

•

The cabin of the carrier must be protected by

means of suitable measures (e.g. armoured

glass) against damage due to flying rock.

•

The cabin of the carrier must allow an adequate

view of the working area.

•

Lighting with a minimum strength of 150 Lux

must be attached to the carrier and this must be

protected against damage.

•

An EMERGENCY STOP device must be

available at every operating and driving position

and this must always be functional.

•

An acoustic warning signal with manual

activation must be available on the carrier and

this must always be functional.

•

All actuation elements present at the operating

and driving position must be equipped with a

dead man's switch.

•

All purchased parts must comply with the

specifications of the carrier manufacturer.

Preconditions for adapter

plate

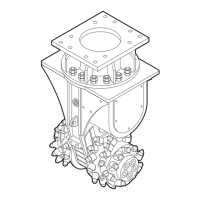

The transverse drum cutter is supplied with a

rotatable upper part. This rotatable upper part has

a standardised hole pattern so that it can be

mounted to an adapter plate.

The mating areas of adapter plate must be ground

plane (surface roughness Ra 12.5 / max.

planeness deviation 0.5 mm)

Note: The adapter plate is not included in the

scope of delivery of the transverse drum cutter.

Manufacturing the adapter

plate

Construction Tools GmbH also supplies base

plates to manufacture adapter plates alternatively

to the adapter plates supplied.

NOTICE Adapter plate cracking

The adapter plate may crack if it is not designed

for the high load.

►

Take not only the weight of the hydraulic

attachment but also the crowd force of the

carrier, possible vibration etc. into account

when dimensioning the adapter plate.

►

Ensure that the design conforms to the state of

the art.

►

Have the web plates welded to the adapter

plate base plate by a qualified welding

specialist.

The base plate is made of the material EN10025-

S355 J2G3.

◆

Have the web plates designed and

manufactured or procure web plates to fit your

carrier.

◆

Ensure that the web plates are welded to the

base plate side marked "TOP".

The adapter plate must not strike in any position

during operation of the hydraulic attachment.

Construction Tools GmbH does not design,

manufacture or sell web plates for adapter plates.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

25

Loading...

Loading...