Depressurising the hydraulic

system

Even when you have switched off the carrier, a

considerable residual pressure can still be present

in the hydraulic system.

A residual pressure can still be present in the

hydraulic attachment even after you have

disconnected the quick-release couplings or closed

the shut-off valves.

The hydraulic attachment can only be

depressurized using the hydraulic system of the

carrier, by allowing hydraulic oil to drain to the tank

via the return connection.

Depending on the type of hydraulic attachment, the

internal leaks, the oil temperature, the type of

hydraulic oil and the design of the hydraulic

installation of the carrier, the time required to

relieve the pressure can vary.

Observe the following steps in order to

depressurise the hydraulic attachment:

1. Ensure that the hydraulic oil in the hydraulic

attachment and in the carrier has a

temperature of at least 0 °C. If necessary, pre-

heat it to at least 0 °C.

2. The hydraulic attachment must be connected to

the hydraulic system of the carrier device, i.e.

the hydraulic hoses must be connected up and

the respective shut-off valves in the supply pipe

and in the connection to the tank must be

opened.

3. Place the hydraulic attachment on timber

support blocks laying on the ground.

4. Depressurise the hydraulic system according to

the manufacturer's safety and operating

instructions for the carrier.

5. You must wait at least another 60 minutes until

the pressure has been relieved through

leakages.

6. When you have made sure that no more

pressure is present in the hydraulic system,

you must disconnect the hydraulic connection

to the carrier. Close the shut-off valves or

disconnect the quick-release couplings, so that

no hydraulic oil can flow back from the carrier.

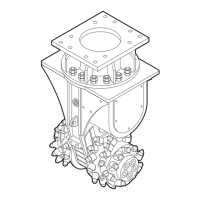

Cleaning

Clean the transverse drum cutter daily after use.

NOTICE Environmental damage due to hydraulic

oil

Hydraulic oil is environmentally harmful and must

not penetrate the ground or enter the water table

or water supplies.

►

Collect any hydraulic oil which escapes.

►

Dispose of it in accordance with the applicable

environmental regulations.

NOTICE Damage due to improper cleaning

►

Never strike the round attack picks, cutter

drums or the gear with a hard object, e.g. a

hammer, in order to free them of a trapped

fragment or contaminant.

Note: When cleaning with a high pressure cleaner,

be aware of the safety labels. These must not be

damaged by a water jet.

◆

Wipe clean areas to which safety labels are

attached by using a cloth.

◆

Clean all other areas of the transverse drum

cutter thoroughly with water.

◆

Remove contaminations in the intermediate

spaces between the round attack picks and pick

boxes.

◆

Ensure that no residual contaminants are

located beneath the pick (e.g. fresh concrete).

Such residue could harden and set the picks

fast in the boxes.

Checking bolted connections

◆

Secure the carrier such that it cannot move

unexpectedly.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

41

Loading...

Loading...