WARNING Hands and fingers being cut

off or hurt

Bores and surfaces can act like a pair of

scissors and cut off or hurt parts of your body.

►

Never use your fingers to check bores or

fitting surfaces.

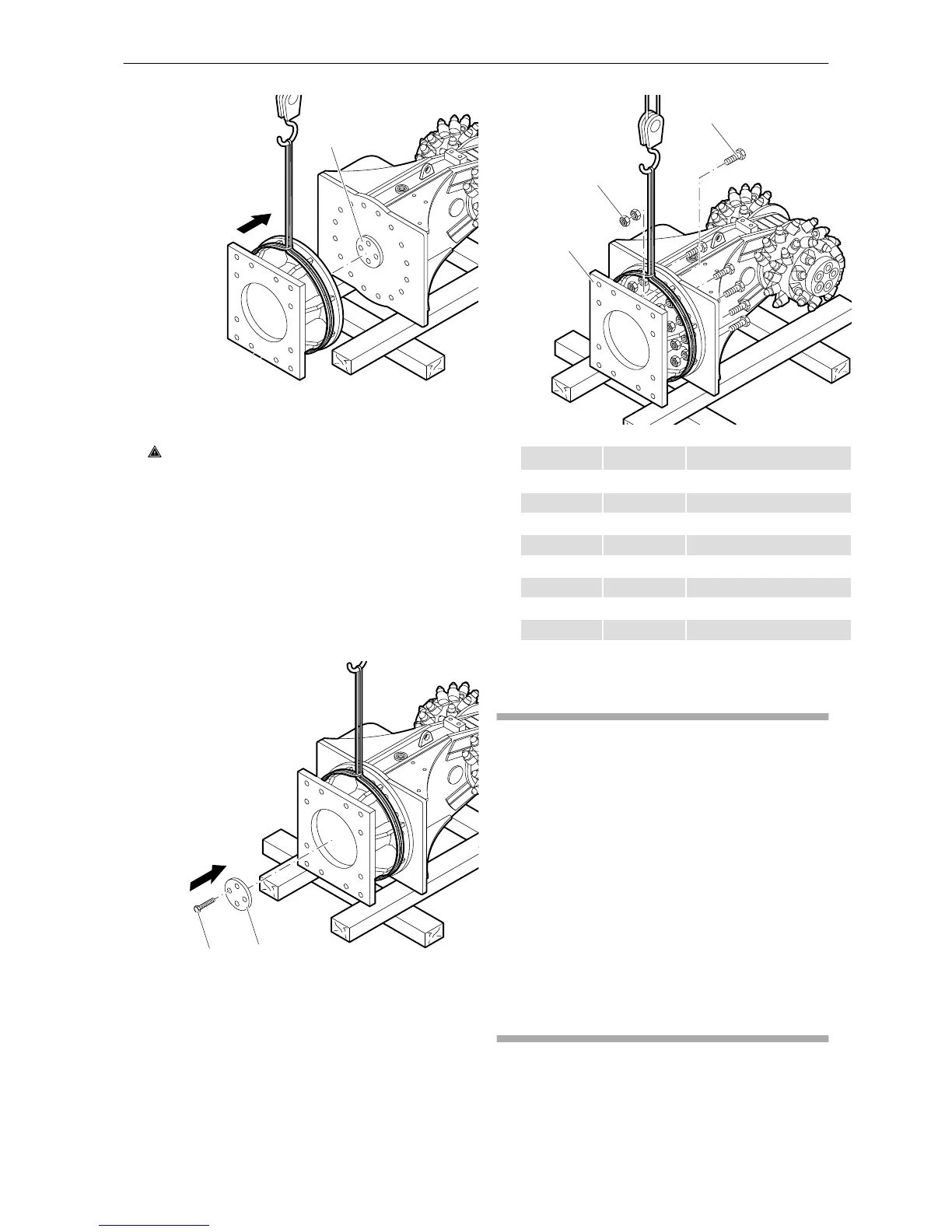

2. Ensure that the hole patterns of the rotatable

upper part and the transverse drum cutter align

with each other.

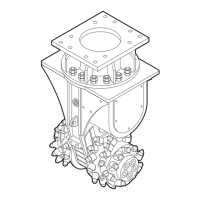

3. Attach the fastening plate (E) of the centre bolt

and fix with the screws (D).

Type Size Tightening torque

DC 200 M 12 84 Nm (62 ft lbs)

DC 400 M 12 84 Nm (62 ft lbs)

DC 600 M 16 206 Nm (152 ft lbs)

DC 1000 M 20 415 Nm (306 ft lbs)

DC 1200 M 20 415 Nm (306 ft lbs)

DC 2000 M 24 714 Nm (527 ft lbs)

DC 2100 M 24 714 Nm (527 ft lbs)

DC 2900 M 30 1428 Nm (1053 ft lbs)

5. Put counter nuts (B) on the screws and tighten.

Checking hydraulic lines

◆

Secure the carrier such that it cannot move

unexpectedly.

◆

Perform a visual inspection of all lines (pipes

and hoses) from the pump to the hydraulic

attachment and back to the tank, before starting

work.

◆

Tighten loose bolted connections and hose

clamps to the torque required (see Chapter

Bolted connections / tightening torques).

◆

Replace damaged pipes and/or hoses.

Checking and cleaning the

hydraulic oil filter of the

carrier

An oil filter must be integrated in the return circuit

of the hydraulic system. The maximum mesh width

allowed for the oil filter is 50 microns; it must have

a magnetic separator.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

53

Loading...

Loading...