OPERON D 850 SURGICAL TABLE

PRINCIPLES OF OPERATION

Rev. 1 700000120

3-4

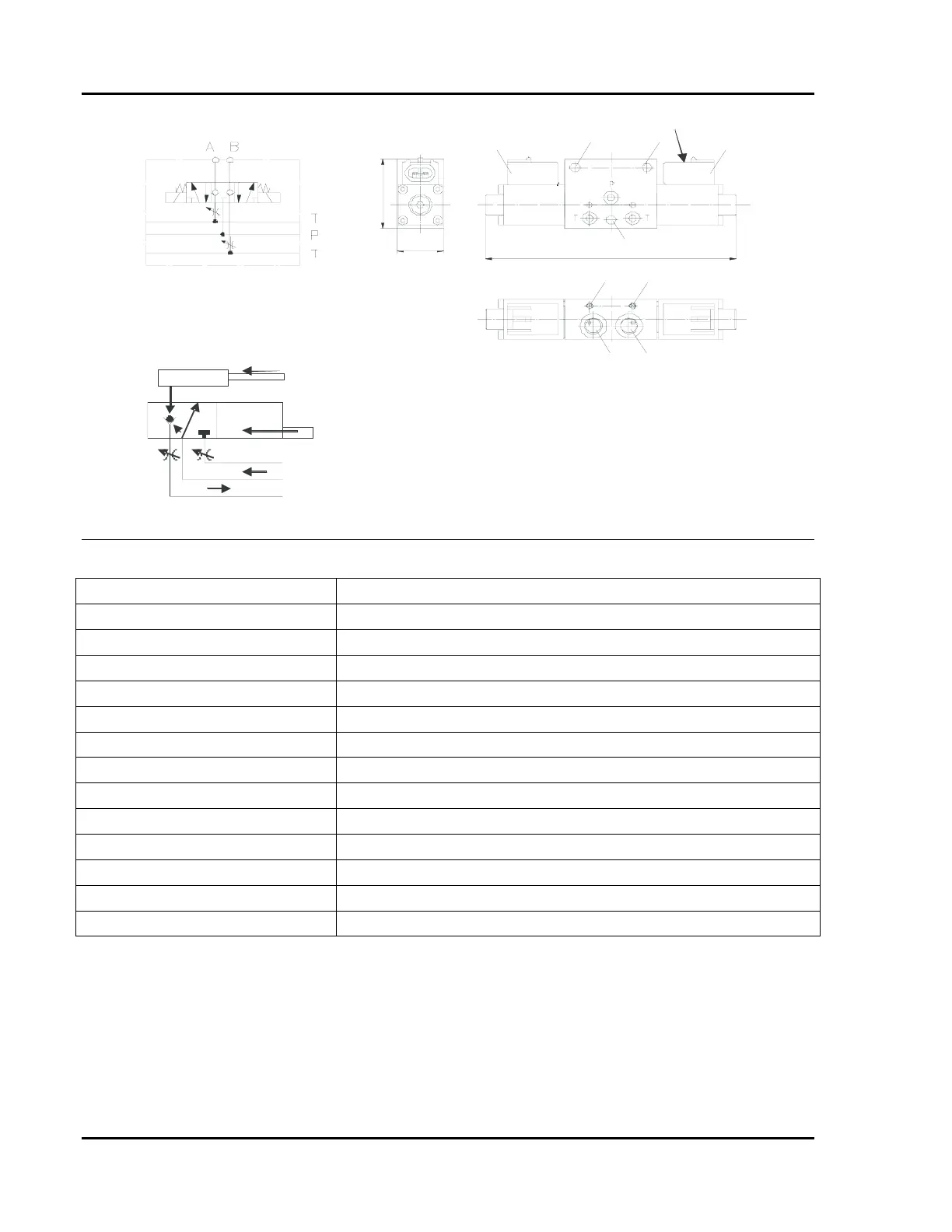

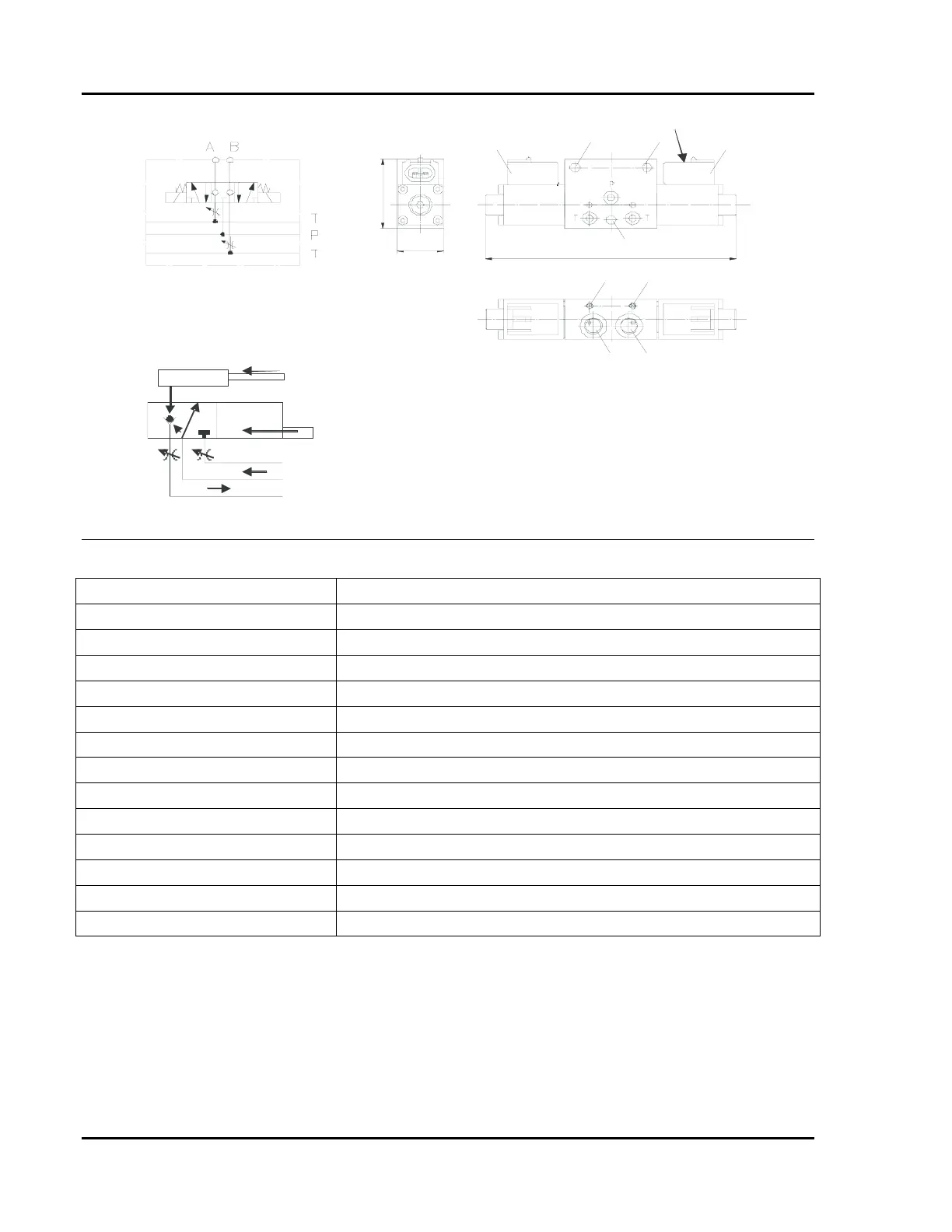

Neutral Position

Energized Position

Solenoid Coil

P Pressure Line

T Tank or Return Line

A, B Outputs Ports to Cylinders

1 Flow Control Adjustment Screws

2 Solenoid Coils Electrical Connection

3 Hydraulic Connection (M10)

4 Mounting Holes (0.21”/Ø 5.3mm)

Item Function

Ø

2

26

ca. 140

3

3

1

1

4

44

2

4

4

Figure 3-6 Manifold Valve

TABLE 3-1 MANIFOLD VALVE OPERATING SPECIFICATIONS

Parameter Range

Operating Pressure Up to 3626 PSI (250 bar) depending on flow rate

Flow Rate 61 in.

3

/min (3 dm

3

/min) maximum

Ambient Temperature -22 °F to +212 °F (-30 °C to +100 °C)

Pressure Medium Temperature

-7 °F to +176 °F (-20 °C to +80 °C)

Pressure Medium Hydraulic oil per DIN51524 and DIN51525

Viscosity Range 0.0006 in.

3

/s to 0.0195 in.

3

/s (10 mm

3

/s to 320 mm

3

/s)

Filtration 25 μm to 40 μm

Installed Position Any

Seal Material NB Rubber

Nominal Voltage 24 VDC (18 to 32 VDC)

Power Consumption 10 Watt (per solenoid)

Electrical Connection AMP Superseal Series 1.5 plug (double-pole)

Duty Cycle 100% ED

Manifold Valve Operation

The manifold valves operate as follows:

1. Hydraulic pressure is applied to the P

(pressure) fitting of a valve.

2. A solenoid coil (item 2) is energized by

an 18V -32V DC signal.

3. The coil forces the 3-position solenoid

spool to move. This is illustrated in the

section of the graphic labeled “energized

position”.

4. Fluid flows from the center pressure line

out to the cylinder.

5. A pilot pressure pushing on the check

valve opens the return path.

Loading...

Loading...