OPERON D 850 SURGICAL TABLE

SERVICE

700000120 Rev. 1

5-7

Auxiliary Hand Pendant

The auxiliary hand pendant is a backup pendant

for use in case of a primary hand pendant

problem, or a power problem that disables the

CPU, main electric pump and/or the primary

hand pendant. It is identical to the primary hand

pendant and can be used to replace the primary

pendant.

The primary hand pendant sends commands to

the CPU via connection J24 on the CPU board.

The auxiliary hand pendant has all the functions

of the primary hand pendant with the exception

of AUTO DRIVE, HI/LO, SLIDES, FLEX,

REFLEX, CHAIR, UROLOGY, RETURN-TO-

LEVEL, OFF, and ON. The active functions on

the auxiliary pendant are back-lit.

An illustration of the auxiliary hand pendant

along with functions descriptions is provided in

the General Information of this manual.

The auxiliary hand pendant provides power to

the solenoids as long as the selected function

button is pressed and held. It does not activate

the hydraulic pump.

There are no field serviceable parts in the

auxiliary hand pendant. It must be replaced as a

complete assembly.

WIRING

The Appendix contains drawing 86799 which

identifies and locates all of the electrical wiring

and electronic components, as well as the

connections for each.

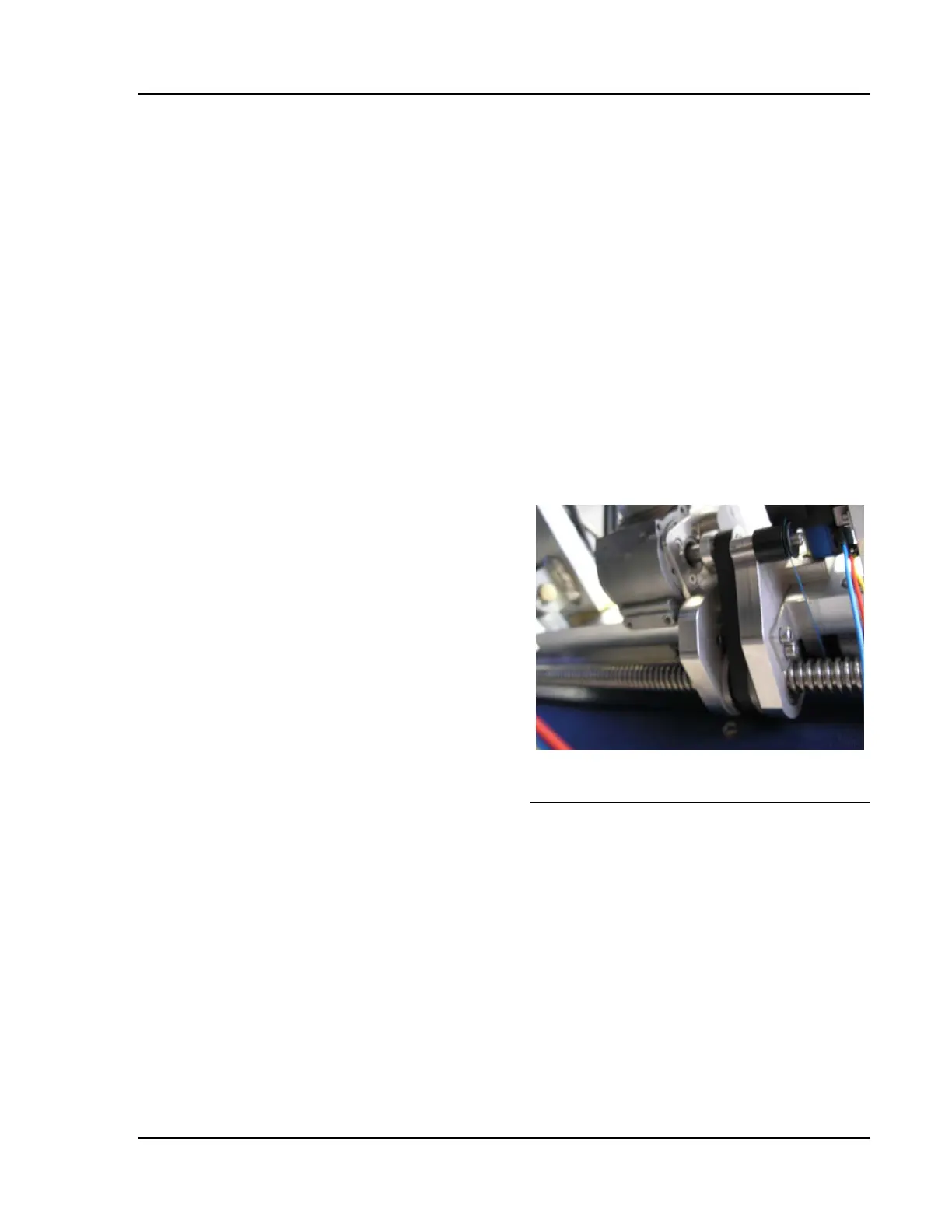

MECHANICAL SLIDE SYSTEM

The slide system uses a 24VDC motor to drive a

timing belt which, in turn, activates a slide screw

to slide the table top from head to foot. The DC

motor is reversible by controlling the current

direction, so no additional gearing is required to

achieve bi-directional motion. The motor is

secured in its mounting bracket by rubber

isolators that prevent vibration transfer to the

frame.

Components of the slide system were chosen for

high reliability and to minimize maintenance

requirements.

The motor provides high torque from a compact

design to fit in the space under the table top.

The motor assembles to the table top frame. The

motor, drive belt, the slide gear screw, nut and

its associated support bearing and mounting are

field replaceable.

Figure 5-16 Slide Screw Drive Belt And

Potentiometer Cable Routing

Loading...

Loading...